hey folks,

recently got bitten by the bug. will attempt to build one based on IKEA liatorp. Question: from your experience; does it have to bee mena17? or would 11 / 14 do?

will likely have more questions… but this is the first one…

I think a smaller motor would work, although I don’t have experience with a nema 14 myself. I do have my motor current turned very far down (0.3A, IIRC). The only friction comes from the belt, basically. There arent any other mount stls available besides the 17s though. I am excited to see your build.

Ignore me, I’m derp.

This is the zen XY, which is the sand machine.

Yeah, where you drag around a hunk of steel with invisible forces!

Well damn, so it is. Whoops.

Im mostly a dreamer but now and then actually finish stuff to. We will see where this lands.

My plan roughly;

- Source a used IKEA Liatorp Coffey table (the square one) - inspired by @2mas hoping to land one around $50

- Measure it extensively and make accurate sketchup model to figure out how much space there is to work with for motors etc

- Learn more about the electronics see questions below

- Source parts

- Build

Random thoughts/wants/background info:

I like the IKEA Liatrop because of W compatibility

I would like my build to be replicatable, easy-to-use and low cost so that we can grow the userbase.

I want the ball to be able to move under the entire glass part of the table with as little “dead” sand as possible

I want warm LED-stip (this will probably need 8-10mm of height)

I concerned that although beautifully designed the zenxy parts on thingiverse will take up too much space vertical.

Im “fluent”/ confident enough in sketchup to produce new parts if needed.

Although I have had 3D-printers for more than 10yrs I have managed to stay away from the Merlin/sailfish/reprap/gcode/rambo side of things.

Would like as silent steppers as possible: need to have the special silent driverboards?

Current Questions:

- Controler board: the ones for sale on this site seems to control 4 or more steppers. From what I gather, I only need 2 - what is the cheapest most hazzle free board to buy?

- Workflow/connections: would like to avoid display, buttons and sd-card change on finished unit. Im guessing/hoping for raspberry pi -> driver board. Is this possible?

Remember that 2mas’s build wasn’t a ZXY. I think that one used smooth rods, IIRC.

Do you want cheap or hassle free? My v1pi image has CNC.js installed, which works with grbl. There are a ton of grbl boards out there. You will need to change the configuration before flashing them to be corexy, so you will need to be able to reprogram it regardless.

Ahh, the old: ’pay peanuts get monkeys’ true here as well… so recomended board: rambo mini?

The mini rambo will work easily. @vicious1, do you preflash for ZXY? Then you can install the v1pi image and use either cnc.js or octoprint (because the MR is Marlin).

No I have never shipped a board flashed with Zen firmware you need to edit the exact table dimensions so you do not mess up/skew the corexy if you exceed the boundaries.

As of now;

1. Source a used IKEA Liatorp Coffey table (the square one) - inspired by @2mas hoping to land one around $50

1. Source a used IKEA Liatorp Coffey table (the square one) - inspired by @2mas hoping to land one around $50

2. Measure it extensively and make accurate sketchup model to figure out how much space there is to work with for motors etc

2. Measure it extensively and make accurate sketchup model to figure out how much space there is to work with for motors etc

3. Learn more about the electronics see questions below

3. Learn more about the electronics see questions below

4. Source parts

4. Source parts

5. Build

5. Build

Im working on a new design for a ”low profile” under carridge and a cpl of questions have come up. Can output from sandify be used on a system that uses x and y instead of corexy?

(Is the actual motor commands done in that gcode or is it interperd by firmware on whatever board you use?)

The output can be used with “cartesian” (regular x and y) machines as well as corexy, etc. The gcode just tells the machine where to go. The details of HOW it gets there is dealt with in the firmware and varies with configuration.

What Pete said. I use a little grbl board with mine. The gcode is pretty generic, since it is just G1 commands driving around. Any of the math to move the motors in a corexy machine is done by the firmware, not sandify.

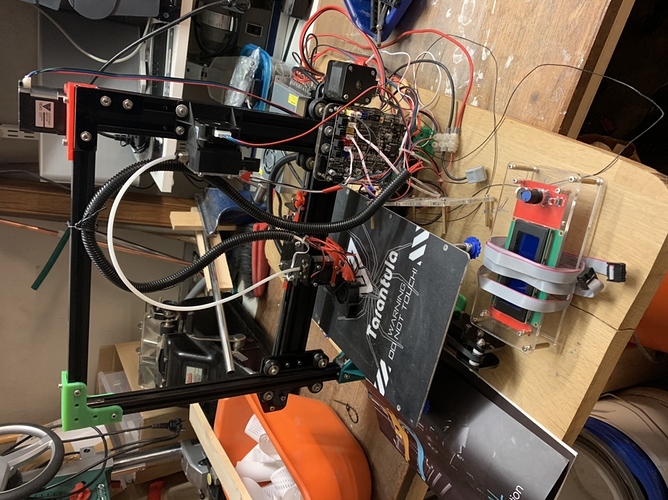

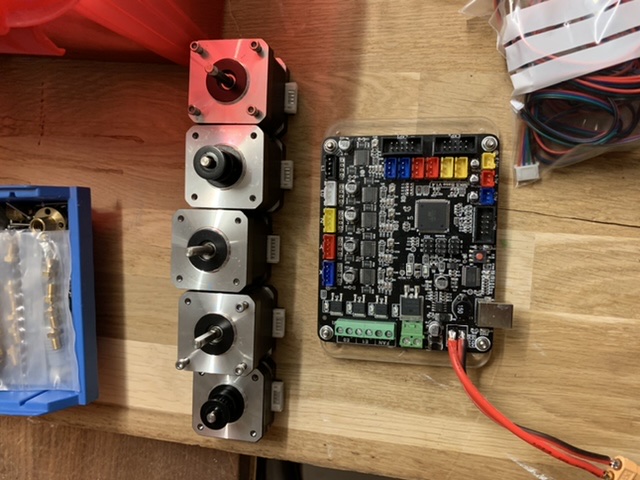

Picked up another donar machine… $60 on blocket / (~craigslist). Then sold the unwanted parts from both machines for $65 on facebook.

Net result: 10 steppers, 2 boards with lcd, 2 china power supplies (a bit scared of these). And a lot of other keeper parts…

Have also spent lots of time on low profile x/y 3d printable parts. no where near yet, but its coming along. Pics to follow eventually

Seems like you and I have similar ideas, just my scrap 3D printer parts came from my own pile, and the IKEA table came from my basement. I chose the LACK table because it’s cheap, and so many hacks already exist for it, I couldn’t resist adding another.

I see in your box of parts 5m of belt… that’s not enough. My Lack table needed 7.5m, taken from a 10m roll. The LACK table is 90X55cm, the LIATORP is 93X93. I dont know what the glass size is, but probably larger than my UTRUSTA glass shelf (35X57cm)

I think you are looking at 14-15m of belt required to go around that span. You need enough for twice around the area, plus a bit for CoreXY kinematics.

I’d like a nice repeatable larger scale table, too.