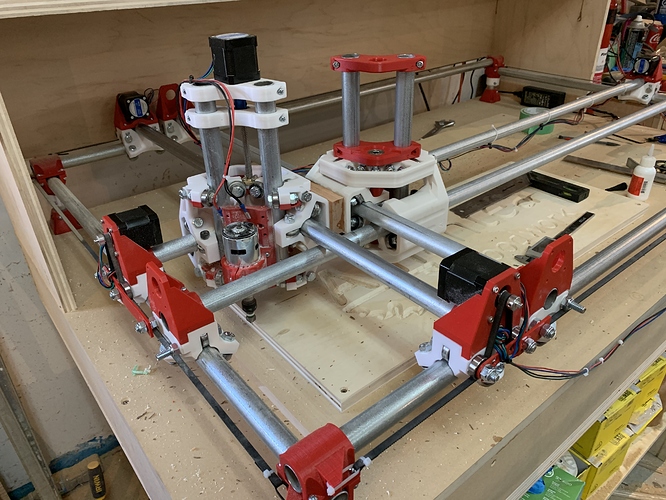

Added some lateral stiffness to the gantry

Yep, that’s weird. But pretty neat. Any plans on mounting something to the other core? Dual operations!

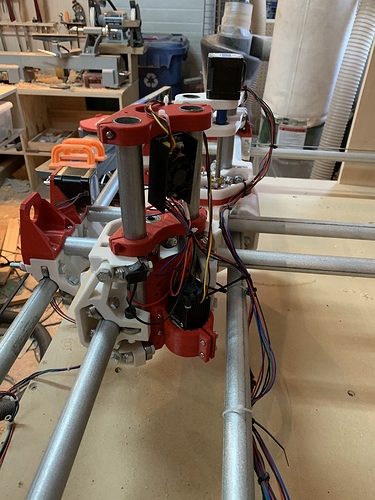

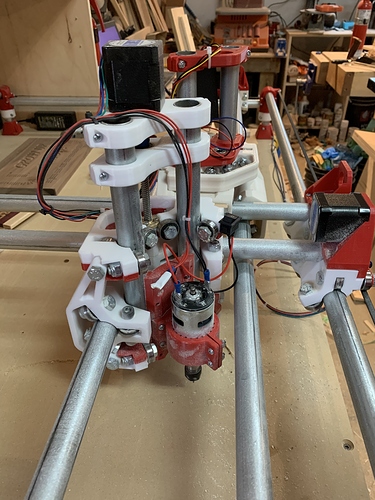

Yeah, actually printing a holder for my laser as we speak. Laser needs no z movement, that’s why there is no stepper in the second z.

Also facing backwards less chance of viewing the laser accidentally

Yeah, that’s what I see. There’s gotta be something like the dual extruder offset that can come into play here somehow.

Interesting.

Pro’s

More stiffness/rigidity in the 3 dimensions as you double up.

Ability to add in extra laser at same time.

Con’s

Larger area needed for space but actual printing area is reduced for the size.

More tubing - Not much of an issue

More printing - Not much of an issue

If you have the space, then this makes sense. I’m fighting for every spare centimetre, so this doesn’t help at the moment, but you never know …

Is there anyway to measure the rigidity improvements?

Thanks

Rob

Maybe also a little extra weight in the total center assembly? Perhaps some mid-span supports on the frame could help there.

My spindle only weighs 396 grams, so my center area is about as heavy as as anyone else’s with their Dewalt 660. So far I have not noticed any sag. Might add some support anyway though.

I lost 2” in the y, and I think 6” in the x. Total cutting area is now 22”x 39”

That spindle is half the weight of mine and you probably have twice the rigidity…

Do you mind telling us where you got it?

Thanks

Rob

Can I ask what Laser you are using?

Thx.

I also use their GRBL based control board