I have not tried a pure bowden in years, I bet they are way better now.

I didn’t like it on my grid bot. Maybe I was just doing something wrong. But I was never trying to break speed barriers either. I still think I am probably printing way too slow.

That is right you tried linear advance and everything right? I thought that might really help.

There are a whole slew of new tiny/light/small direct drive extruders coming out now. Bondtech has one, there are others. Orbiter maybe? I would like to try one, just unclear which to try…and they seem pretty pricey.

With Core XY drive system you have one motor that drives X-Y and another motor that drives X+Y.

Add another motor and belt and maybe you can make a “Core XYE” system where the third motor drives X-Y+E.

Or May I throw out the idea of Remote drive. Where the motor is attached to a drive cable type thing.

Sorta like this.

I used to think that was the best idea ever, but it turns out that drive has about as much free play in it as a regular Bowden, but the cost significantly more.

I did. But don’t take my fail as a real data point. I was also trying to figure out some phantom bed issues back then.

The thing I just couldn’t shake was that corners just always looked rounded over. I just couldn’t figure it out.

But there are a lot of people, with a lot more experience than me, that are convinced.

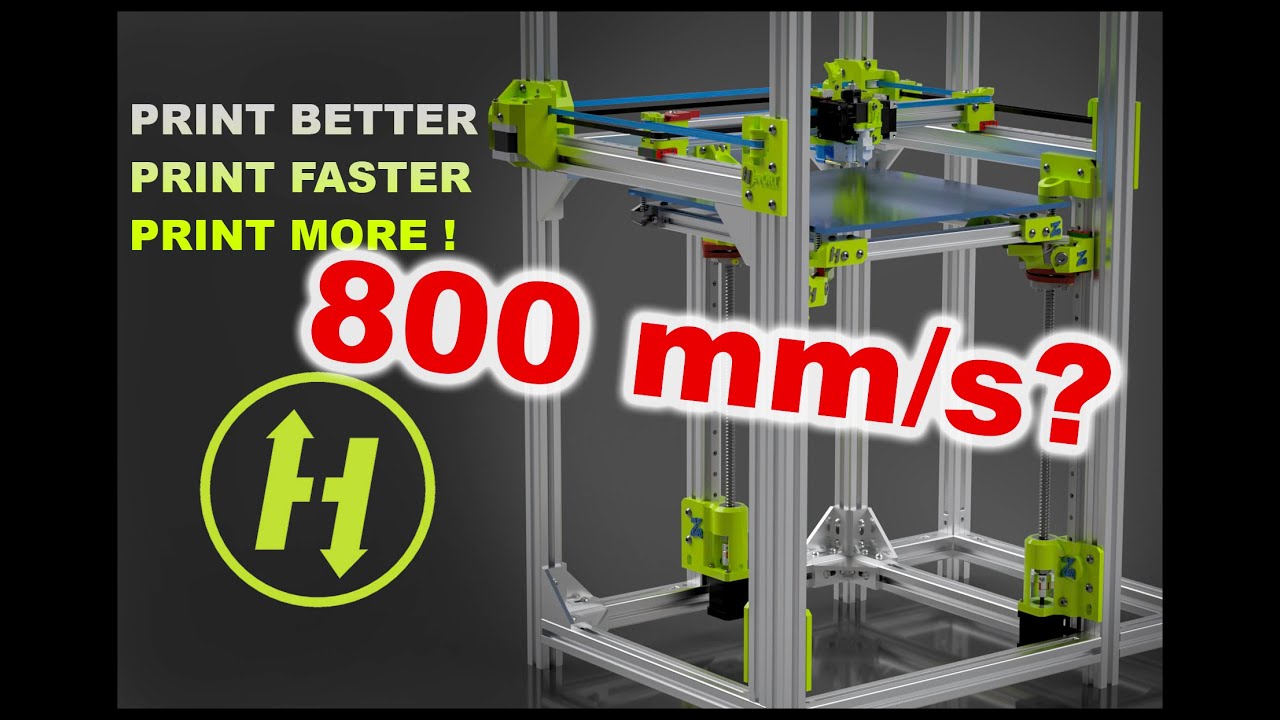

There are some very fast printers that use direct drive though:

In general not a great idea, even for expensive, high-quality printers.

You can run them unattended, but I’d always check on them in regular intervals.

I had a horrible thing happen to my printer maybe two years ago now, using possibly too old (?) PLA filament.

It probably bubbled strongly while being extruded and started caking up all around the nozzle, which caused the extruded string at some point to catch the debris, and it all went down stream from there.

It kept on printing and printing until the entire extruder and everything around it was covered in PLA. At some point pressure inside the extruder must have been so high that material started to flow out of the tiny tolerance gap between the heat break and filament inlet.

I managed to clean up some metal and hard plastic parts with a heat gun and lots of patience - imagine an archaeological excavation in plastic -, but the extruder couldn’t be saved. It had bent itself at a certain point and inflated the thin heat break. It was a mess!

Mine did that the other day. But it was recoverable.

I just heat it up a bit (I think I did 160C) and it come off the hot stuff pretty easily. The cords were my big worry, but some careful plastic cutting with flush trim cutters and it was free.

Hehe, I knew that would come up. I agree with you, but my life is too short to only print when awake…

NIIIIIICE!

I love it.

Can you believe some people put cars in nice work spaces like that?!

I put Harleys in mine.

Looks like you are right on track with our LR3 build, By the weekend you will have all the furniture and every little thing in place, “by wife request”,  and plenty off time to play with us

and plenty off time to play with us

we know you have all the parts printed already!!!

we know you have all the parts printed already!!!

I’ll see your rain and raise you moving in Texas in August…

Yea, we moved here last August. Was 95 the day we moved in.

Ah. So you had a cool front roll through. Lucky

Good luck on the move. I love starting with a clean slate. I do wish I had spent more time in the initial setup of my shop. I did quite a few things to ‘just get it out of the way’ and I’m pretty sure I’ll never actually go back and do it the way I wanted. Initial plan was to put in all cabinets with doors to house everything to keep dust off of stuff. And I ended up just re-using a bunch of knock together metal shelving units.