Hello everyone

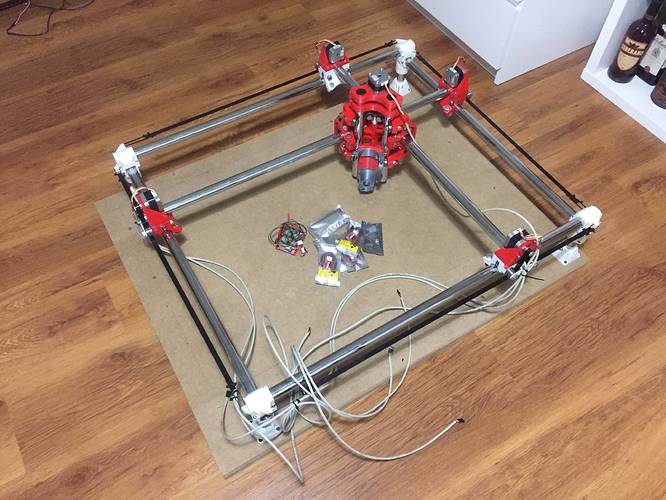

so I just bought myself an unfinished MPCNC. It seems pretty well assembled but there is some stuff to add and fix. I have a few questions and I’m hoping You guys can help me out a bit.

- The machine has some slack from the Z screw and nut so I want to replace it with a proper leadscrew and an anti backlash nut. Will something like this fit inside the standard Z axis assembly? Also has anyone tried using these on an MPCNC as I think these might be even better?

- Should the belts be steel or glass fiber reinforced?

- I need to get a spindle for it but for now I want something cheap and reasonably quiet (quiet as in spindle quiet, I know cutter makes noise regardless) Is this spindle with the "mach3 power supply" any good to get started or just complete garbage?