As I knock one item off my ‘todo’ list, more seem to pop on.

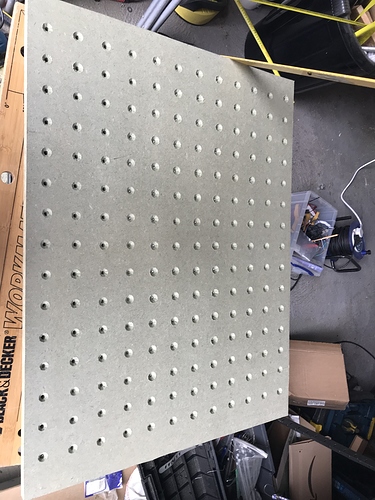

I have already seen that the bed of my MPCNC is not level, though it’s pretty flat.

If I look from bottom left (0,0) towards top right, it was clear that a pen that was lightly touching the bed, but as it went to max X and max Y (top right), it was around 1mm to 1.5mm off the bed.

So I thought I’d measure what was out. Simple enough job…?

So I pulled out my cheap digital caliper. I only trust these to 0.1mm as they were exceptionally cheap about 10 years ago, but that’s enough margin for me.

The first problem is that they aren’t designed to work the way I want them to, I want to measure the distance from the bed to the 25mm tube. The calipers are designed to measure stuff inside the jaws and there’s no nice long flat level edge on the top or bottom of them to rest against the bed. So I thought I’d actually design something in Mac FreeCad to hold the head of the caliper in a stable position and at right angles to the bed. I’ve never used anything but Google Sketchup for design and that was 6-7 years ago, but it can’t be that difficult, can it> Well, I can now scrub Mac FreeCad off my list of well designed and stable Mac products. After the 5 or 6th crash in an hour I gave up. It was just impossible to keep it going.

So I then moved to Fusion 360, it’s free, I’m not breaking any license terms as my income from this is significantly less than £0 to date. It then transpires that you need to have some sort of brain operation twist your brain through 90 degrees to get the hang of it. All I wanted to do was draw a simple block, put two screw holes in it and cut a T out of it. Six hours later and feeling like I’d reengineered the entire Apollo space program, I had two blue blocks in my hand, that 1) fitted my calibers 2) were stable.

I look at the simple (and it was simple) block and look at what Ryan has engineered for MPCNC and I want to cry. Six hours to get two blocks of printed plastic (and eight blocks thrown in the bin as they were wrong). How the devil did Ryan design the thing of beauty that is the Z gantry? Was there a crossroads at midnight , a bloke in a black hood, animal sacrifices and Robert Johnson involved?

Anyway, I now have a device that I have designed and printed by myself and I start to measure my MPCNC. I realise that the absolute numbers are irrelevant and that it’s the difference that’s important.

So here they are:

I have tried to keep this simple as there are lots more measurements I took  I have started building up a mesh. You’d never guess I love data…

I have started building up a mesh. You’d never guess I love data…

Bottom left (0,0 ish) is the datum point. What I am measuring here are the Z values, a +ve Z value is out of the bed and up in the air and a -ve Z value is towards the floor. This matches the Z axis movement in Marlin.

The numbers back up what I thought. The gantry is very slowly moving away from the bed as it moves along the X and Y axis.

Now there appears to me to be two solutions:

-

I run a small planing run across the spoil bed (not shown) to level it.

-

I shim the stepper motor mount points on the X and Z axis tubes that hold the Z axis gantry by a small amount so they are trued.

Since I have to do point 1 anyway, is there any value in shimming the stepper motor mounts. It’s easy enough to print a couple of 0.6mm and 0.3mm shims to level things up, or am I worrying about things that I should ignore.

Views and comments welcomed.

Rob

It’s partly to avoid using those fiddly little connectors for DuPoint and JST fixings. Still waiting for the scars on my fingertips to heal.

It’s partly to avoid using those fiddly little connectors for DuPoint and JST fixings. Still waiting for the scars on my fingertips to heal.