I have a manual way to reduce lead in on the How-To page. It should not be noticeably oval, maybe a little less pressure or better hold down? If the hold down tape was loose at all it will change all sorts of things.

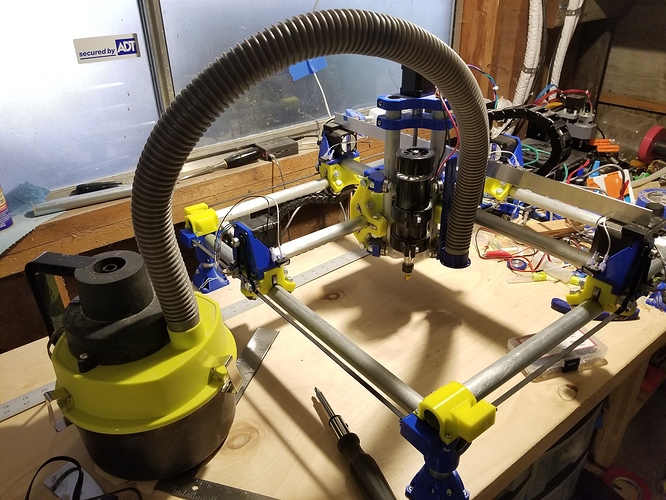

Just wanted to update that I’m finally getting the machine dirty

I finished cleaning up and routing wires, added Jamie’s awesome joystick and moved it out to our storage space under the sunroom. No climate control, but it’s insulated at least.

500W china special spindle mounted up and cutting!

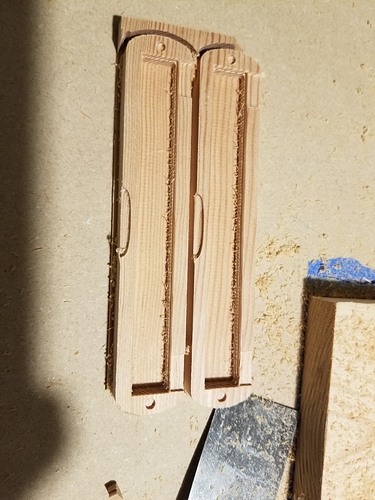

Got some more time in. Made a quick dice box in doug fir. Only 2 min cleanup, not too bad. Pockets I created for hinges needed to go all the way back instead of leaving a 1mm space and I think I’ll pre-drill the screw holes. End holes are for magnets to secure the box when closed.

Hardest thing was definitely figuring out CAM steps that would produce nice results without taking ages.

Next trick is finding something nice to engrave or inlay into the top.

For reference, this is a smaller 12mm die.

Fun project. Now that you have the basic shape made you can swap it out for all sorts of designs on the top in a short amount of time. I have a feeling you might get some requests from friends for custom ones.

And once Con seasons resume…

In parallel working on signs for kids rooms. Carved from red oak, sculpey inlay with bake and bond glue, baked (lower temp, longer per youtube tip) and then faced and sanded. Pretty happy, but it’s not as clean as I’d hoped. Sculpey ended up being a bit brittle and chipped off some.

Still, kids are happy. Just need to pick between danish oil and minwax finishing paste wax after testing on some blank wood.

Hey, it’s sign for a room full of kids right? You think there’s ANYTHING in the “real” Ravenclaw common room that ISN’T scratched, chipped or dented? 8^)

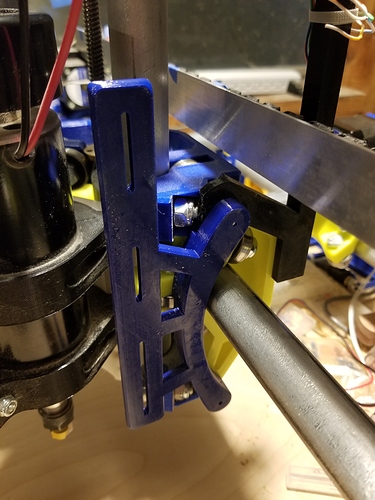

I shrank it by 20" and am attempting to add dust collection. I made a magnetic mount that attaches to two bolts on the middle bit. The hose holder is height adjustable so I can set it to the top of the workpiece. I still need to design the end that actually sucks near the bit. I was a bit worried about the short hose not twisting gracefully and the magnets (and sleeved bolt heads) wouldn’t be enough, but I can jog the machine extends w/o issue. Hopefully no torsion on Z since it’s not attached to the Z.