Here’s the pricing and parts breakdown so far, if anyone is looking to replicate this in Australia.

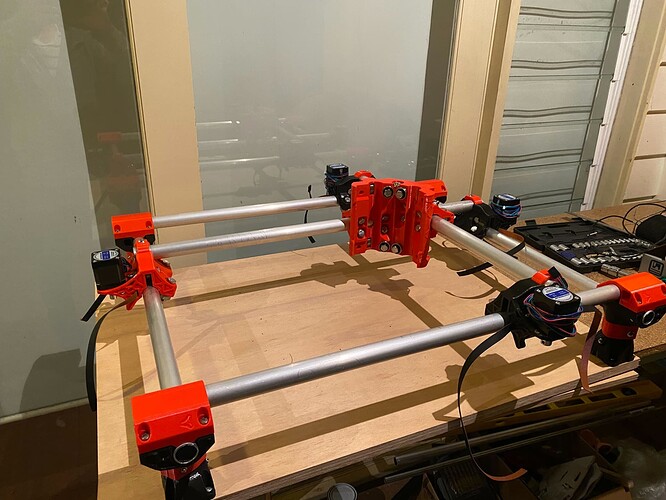

I’m building an F model, with 25mm conduit. Initial build is default sizes as per the MPCNC calculator,

450mm x

330mm y

81mm z

MPCNC parts printed using an Ender3V2, ESUN PLA+ red and black filament from Jaycar. $39.99 per spool,

Total - $80

Conduit - Metal Mate 25mm x 1mm x 3m - 2@$27.21

Total - $55

Stepper Motors - AliExpress

[5PCS Nema 17 Stepper Motor 4-lead 48mm 59Ncm(84oz.in) 2A 1m Cable (17HS4801) Nema17 Step Motor for DIY 3D Printer CNC Robot XYZ] -

Total - $79

Bearings - ebay, [10pcs/set 608-2RS Rubber Cover Sealed Shafts Deep Groove Steel Ball Bearing H4AU] - x6 pcs,

Total - $31

Hardware - Konnect AU -

|Hex Head Bolt Stainless Steel DIN931 G316/A4 M8 x 40mm|50|$0.46|

|Machine Screw Stainless Steel Pan Head Phillips G316/A4 M3 x 10mm|30|$0.10|

|Machine Screw Stainless Steel Pan Head Phillips G316/A4 M5 x 30mm|70|$0.55|

|Hex Lock Nut Nylon Insert Stainless Steel DIN985 G316/A4 M5|70|$0.06|

|Hex Lock Nut Nylon Insert Stainless Steel DIN985 G316/A4 M8|50|$0.15|

Total - $84

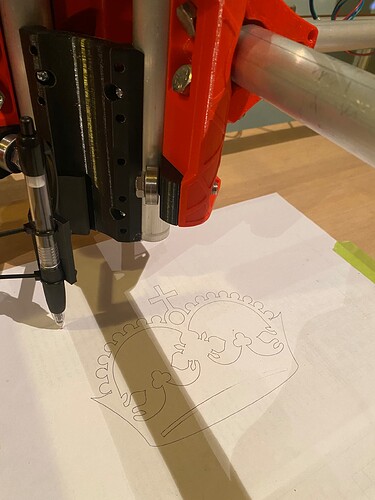

Makita Router - Bunnings - model RT0700CX

Total - $269

Pulleys, Timing Belt, Idlers - AliExpress

LINK CNC GT2 Timing Pulley 16 teeth Bore 3.17mm 4mm 5mm 6mm 6.35mm for 2GT Synchronous Belt Small backlash 16Teeth

5mm, 10mm, Silver

AU $0.64x5

LINK CNC 3D printer 2GT Open Timing Belt width 9mm 10mm mute dustproof For Motor

10mm, RF dustproof

AU $1.87x4

LINK CNC 2GT 20 Teeth synchronous Wheel Idler Pulley black with Bearing for GT2 Timing belt Width 10mm 20teeth 20T

A bore 5mm, silver, For belt width 10mm

AU $0.76x10

Total - $33

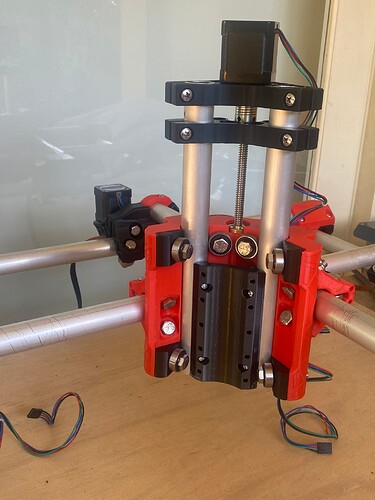

Couplers - AliExpress

4pcs Aluminium CNC Motor Jaw Shaft Coupler 5mm To 8mm Flexible Coupling OD 19x25mm Dropshipping 3/4/5/6/6.35/7/8/10mm

5x8

AU $6.32x1

Total - $7

Lead Screw - AliExpress

3D Printer T8 Lead Screw Trapezoidal OD 8mm Pitch 2mm Lead 2Mm 8mm 200mm 250mm 300mm 350mm 400mm 450mm 500mm with Repair Nut

Pitch 2mm Lead 8mm, 300mm, China

AU $7.40x1

Total - $8

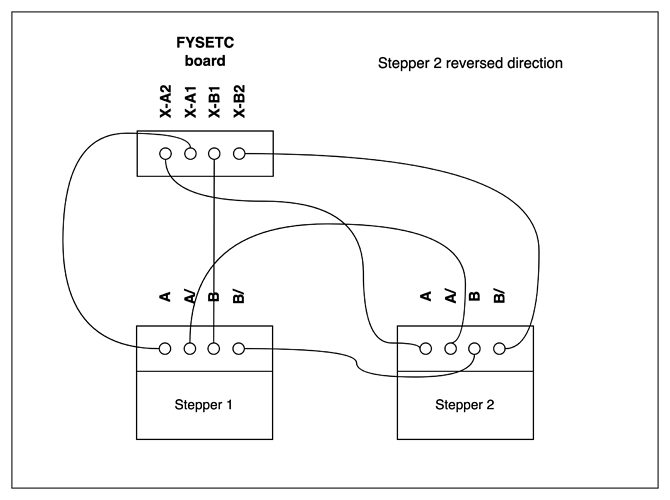

For a controller board I’m using a mates FYSETC with FluidNC so far. Have yet to test this out with the steppers.

For the base board I’m using Marine Ply sheets from Bunnings, 18mm and 12mm. Total - $120

Total cost so far $766. Not expecting that to increase significantly from here as all parts have now been sourced.