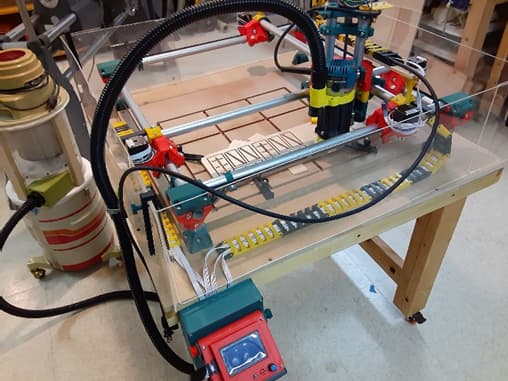

Finished the MPCNC build recently and wanted to post some info on the build. The build bed is approximately 450mm (18”) square with a build height of approximately 89mm. The router is a Makita RT0701C. To keep the wiring neat, cable chains were printed and added as pictured. In addition, an enclosure to house the controller board and display was added and a dust collector/router holder system was designed and added. The files for the electronics enclosure and dust collector/ router holder are posted on Thingiverse. Following are descriptions of the table, electronics case, and dust collector/router holder.

The table is a simple construction of 2x4s, 3/4” shelving pine boards, and ½” and ¾” MDF panels.

The table base is constructed of 2x4s held together with 6” carriage bolts. Lockable casters are added to make the table easily movable around the shop.

The table top frame was constructed of pine shelving boards (3/4”), providing a level frame for the MDF table top.

The table top was constructed of ½’ MDF screwed to the table top frame, providing a flat surface for mounting the MPCNC and build bed. This structure provided a surface that was flat in the X and Y to well within a millimeter.

Next, the MPCNC was mounted, leveled, and checked for square. Many descriptions of this process on the site so not included here.)

After mounting and checking the basic functions of the MPCNC, a cable chain assembly was printed and added to keep the cabling orderly.

A sacrificial build bed of ¾” MDF was added. Once the bed was attached to the table top, it was leveled using a surfacing cutter and T-slots added hold downs. (Surfacing the bed and cutting the t-slots made quite a mess of MDF dust. I’d suggest getting your dust collection installed before cutting the slots.)

To tidy up the build an enclosure for the electronics was printed and installed on the side of the table. The enclosure contains the Rambo 1.4 board, LCD display, two fans, and the electrical connections. This case is on Thingiverse at (thing:5359280).

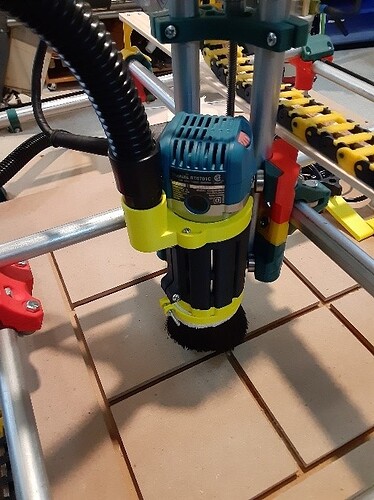

To address the dust that the MPCNC produces I looked for dust collection designs and ideas. Nothing worked for me so I designed the following. It has the advantages of being integrated with a router holder, takes minimal build bed space, and has a removable skirt base. So far, the design has worked well to collect chips and dust during several sessions. The design is on Thingiverse at thing:5431747.

The dust collection/holder design integrates the router holder and dust collector for a Makita router for the MPCNC Primo.