Good to know I’m not.telling my BIL dust is OK not.my place I just helped

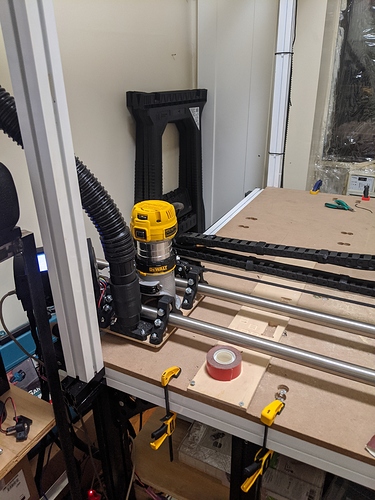

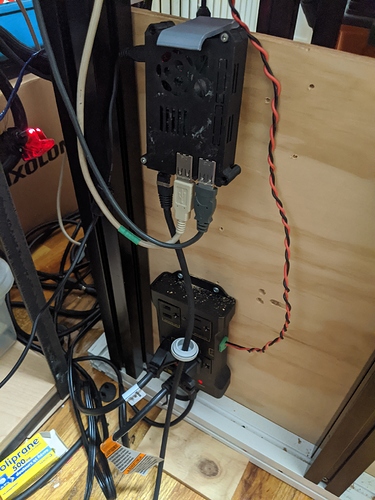

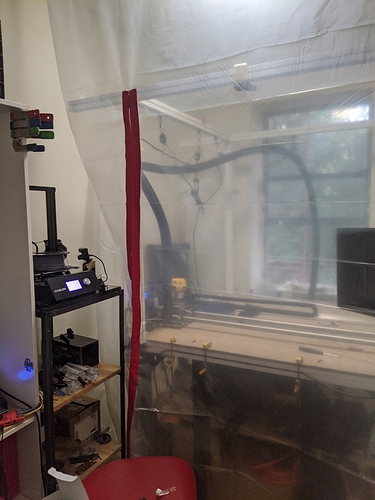

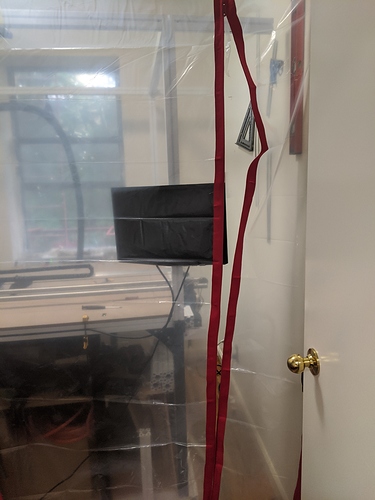

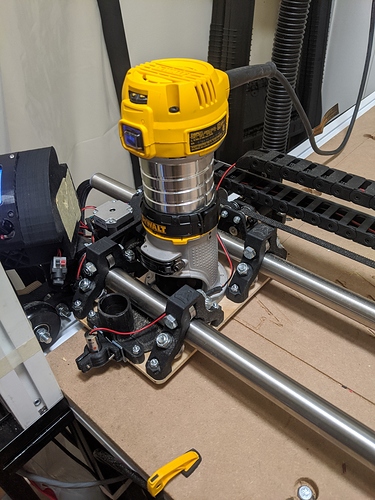

Here is the update from work done this week! All I need to do is add the air filter that arrived today and I think I’ll be done for a bit. I got a SuperPID controller for the router but think about getting a 2nd router to take apart, maybe a Craigslist deal as to not kill my warranty in 5min.

Nice! I’m working on my dust collection system so this gives me some good ideas.

Great! Glad I could be of assistance! It’s really helped me not to bug out over the amount of dust I’m going to generate in an apartment bedroom next to some 3d printers…good ol NYC

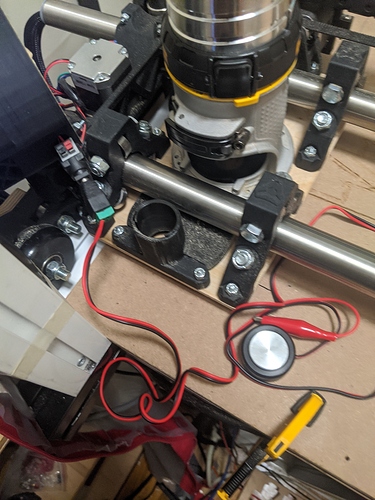

So I spent majority of the day tuning/testing yesterday but I did get a chance to hook up this bad boy that came in the mail!

No more paper sliding! w00t

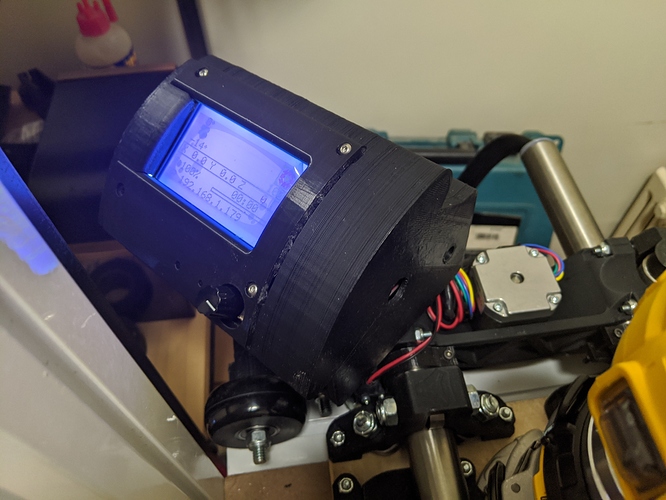

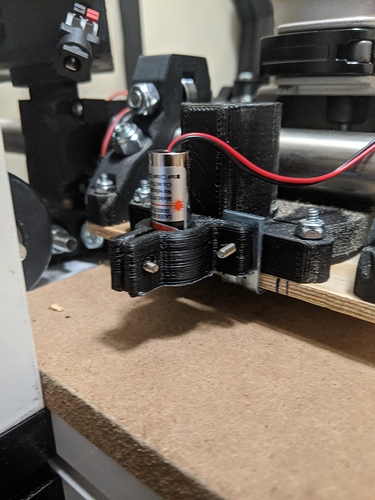

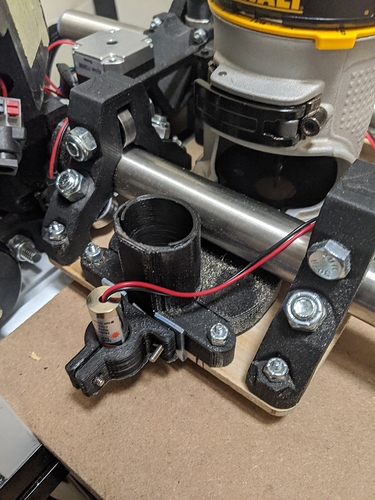

Ok so here I might have lost it but here’s a targeting laser for setting x0 y0 position!

Some of you might think this is worthless but since I started using one on a cammaster machine a few years ago it’s hard not to go back to it. Super easy to add, just a bunch of gcode. Between this and the z-probe I’m super excited about this machine! Thanks for your designs @vicious1

So, you jog until this is at 0,0. Then the gcode knows the offset, so it moves the machine tool there and sets 0,0? Neat. I guess you could also set the reverse of the offset and not move.

That is exactly how it work Jeff. Super easy to setup. I can provide the direction and g code if anyone wants. I only perform the move the confirm the position at the end. You could just set the position and leave it where ever it is.

I have a big bag of red line lasers sitting here!

DO IT! it makes setting my X0Y0 so much quicker IMO

Great build. Could you please elaborate a bit what you actually do in the GCODE? is that a custom command you mean for your LCD or something you add to the start one?

@mrjadez the gcode once you have chosen the position with the laser is as follows:

G92 X0 Y133 ;Reset Coordinates to the Laser

G1 X0 Y0 F6000 ;Moxe to X0 Y0

M42 P57 S0 ;Turn Laser Off

Y133 is approximately the distance the laser is from the center of my bit. Essentially what you want to do is reset X and Y to the position of the laser. To make it easy for myself I drew some lines on my spoilboard with a pen and then lined everything up at the highest point in the Z axis.

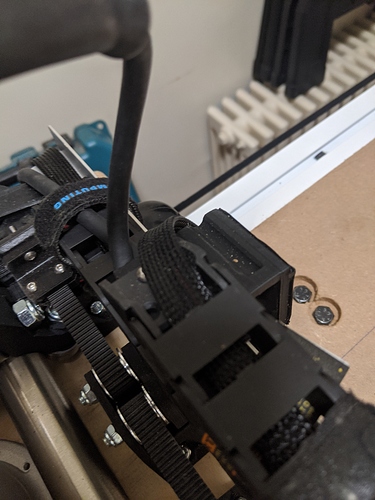

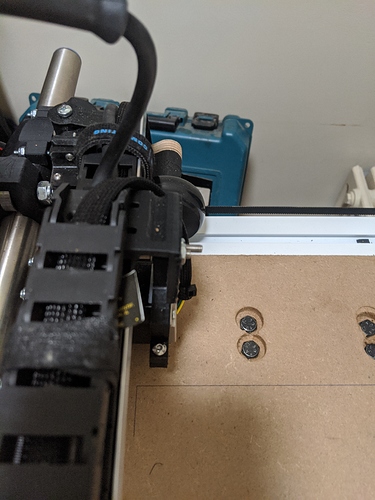

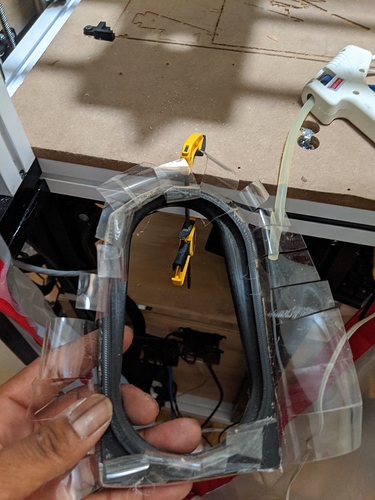

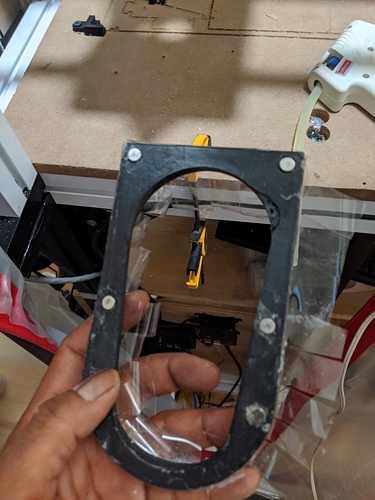

Check out my dust shoe! It works surprisingly well. Attached with 12 some small magnets

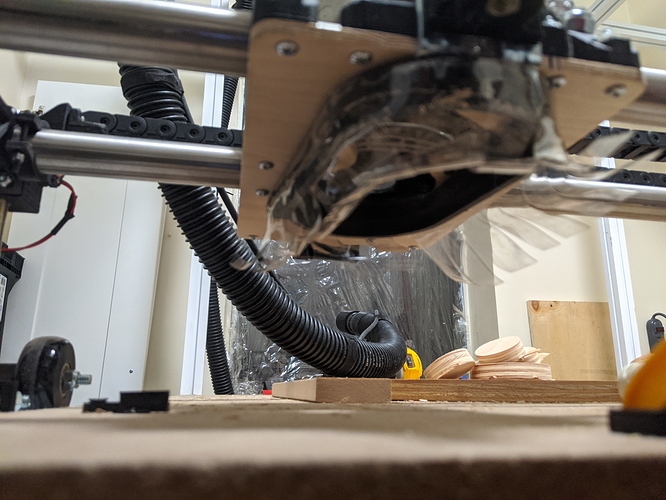

I also added some extra wheels underneath in attempts to create some more rigidity in the gantry, we’ll see if it actually does anything

Nice let us know how it goes. I’ve seen a similar design on dust shoes for workbee and they apparently work great but they were using cyclone via bearings or magnets. I will see if I find a link.

I am just finishing up my build. Wired it all up and I have some weird static and screen powers on on any axis movement even though there is no power source?? Ftw.

I’ve tried disconnecting each axis and trying just one and still same issue.

Ok powering it on after flipping lcd wires on the Rambo the axis each works fine. Not sure why moving motors produces the static to power the lcd. New to stepper systems so not the smartest with all of this!

I think moving the motors by hand makes them almost like a generator. My Rambo did the same thing

I get the same static when I move it off power. I’ve seen this mentioned before.

Are those sweeper sheets on the dust shoe rigid enough to hang down and actually block the thrown pieces?

There’s no almost about it. There’s no functional difference between a DC motor (stepper or otherwise) and a DC generator. Coils and magnets convert between electric energy and kinetic energy/torque. In fact, you need to be mindful of that fact, and not shove your gantry around all willy-nilly. If you generate sufficient back-voltage, you could fry your controller/drivers (or at least, pop a fuse). Some controllers are more robust (IIRC, the Rambos have decent protections), while some just let the magic smoke out if you look at them while thinking about moving the gantry…

How are those bottom support wheels going for you? Ryan’s original was essentially this from what I’ve seen but bit more structured like a classic v-slot panel with 4 wheels on a rail concept. In v2 he ditched those bottom wheels so I never bothered adding support at bottom of the v2 design.

Be interesting to know if it makes the gantry more solid on alu cuts as I have some plans for future cutting.

They were until they got caught up int the router bit somehow. So im trying out some different materials now, I will report back