I’d say it was a long journey to get here but I only just found this website 2 weeks ago! Dug into the forums and decided on the size I wanted and started printing the parts the moment all the plastic came in the mail.

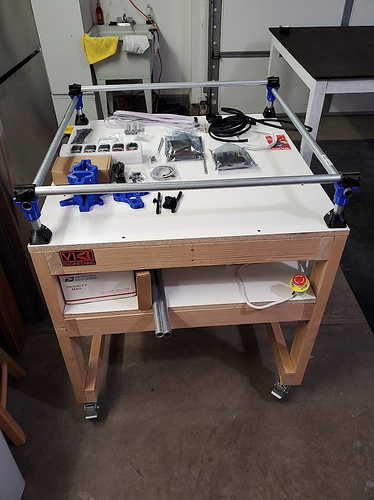

Built this table the following weekend after I heard a 2’x2’ build area was sturdy enough for wood.

Started putting it together before all the parts were finished printing haha

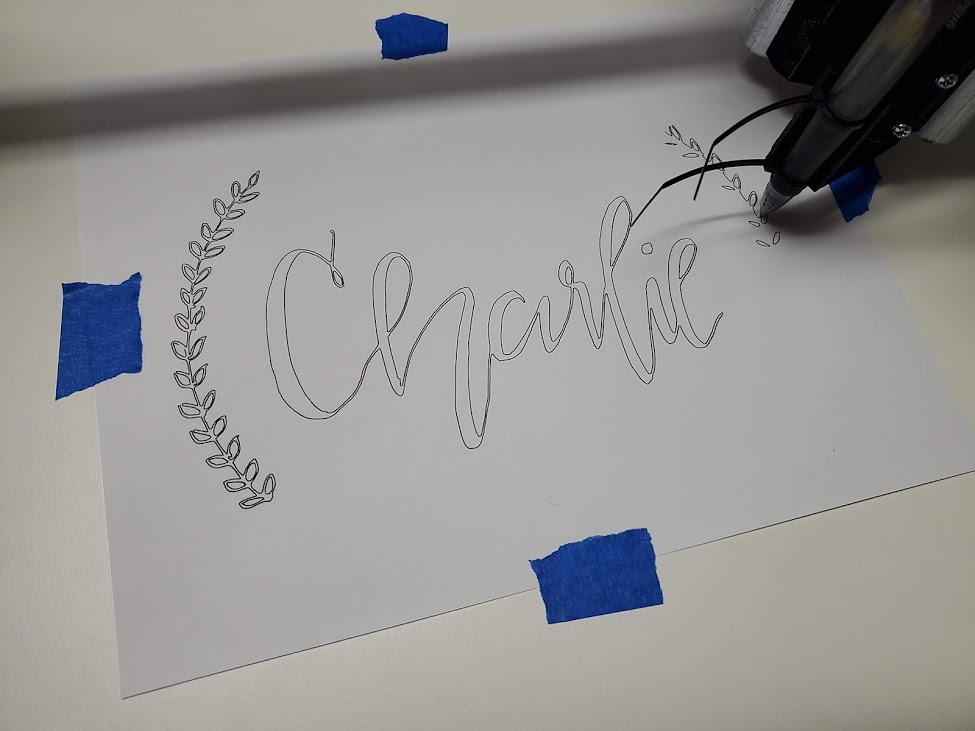

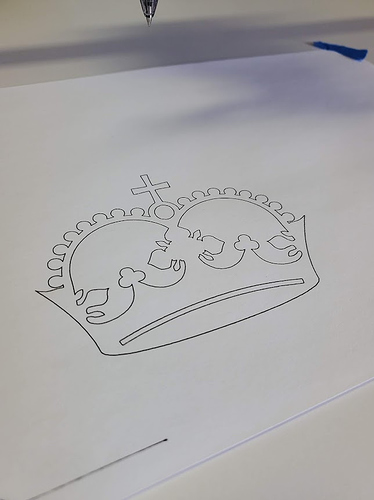

And aside from the really long tension bolt from being too tight for the first test, it still worked remarkably well! I even figured out how to convert my Wife’s art into dxf files that i could draw with.

And finally Last night the DW660 came in and I was ready to start cutting! I started with the foam because I was pretty worried I’d ruin something, but it turned out surprisingly clean for my first CNC projects.

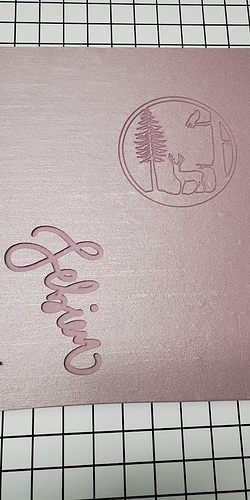

Then my wife threw together a quick little home sign and I dove into Fusion360 (I’ve been using it for years with 3D printing) and I got the CAM all set up for my first wood project.

I couldn’t be happier with this experience and I’m really grateful for all the help I received from the Forum! It’s felt longer than 2 weeks but man am I excited to dive into more projects! Now i just have to clean up all the cables underneath the machine and figure out how to use all my different end mills I bought from the store!