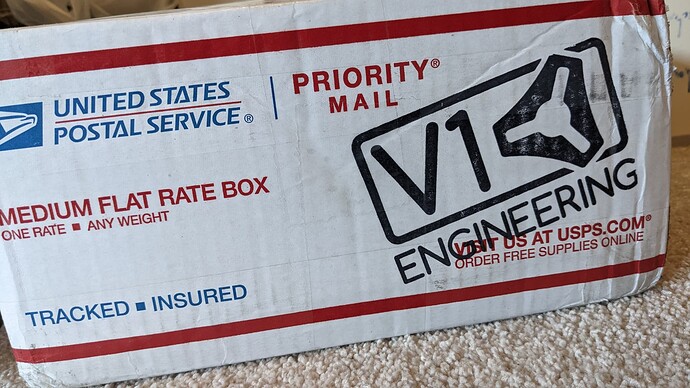

So the journey begins, Primo kit and extras already arrived from Ryan!

I’ve acquired the tubing, after guidance from the forum not to buy pipe, due to one focused on internal diameter vs outer diameter. Originally looked at conduit but was put off by the galvanized finish, many recommended DOM but I settled on the more expensive stainless steel as I didn’t want to deal with ‘potential’ rust. As Ryan’s design looks so good I want my build to have the a polished look. I purchased the pipe from Metal Supermarkets and also had them make all the cuts I need for a 12" x 24" work area.

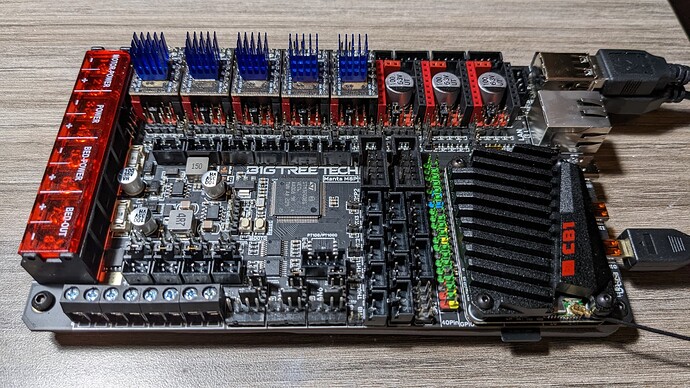

As a fan of Klipper I went with the Manta M8P, which has the added benefit to drive a couple extra steppers if I can come up with something creative. The benefit of the Manta is that it hosts an on board Raspberry Pi (Compute Module version), in order to communicate with the control board. Granted this is a little overkill for the CNC, but I really like my 3D printing workflow with Klipper and wanted to mimic here. Due to the supply chain issues of an actual Raspberry Pi, this solution made perfect sense as BigTreeTech produce their own Compute module, the CB1, more readily available and a small step in performance above the Pi 3.

I’m hoping to leverage an old monitor to display the Mainsail interface, with a remote keypad for control. I’ve already tried running a lightweight browser on the CB1 to view Mainsail, but it’s a little too clunky from a performance perspective. So I’ll consider switching to a Raspberry Pi CM4 in the future or repurpose an old laptop.

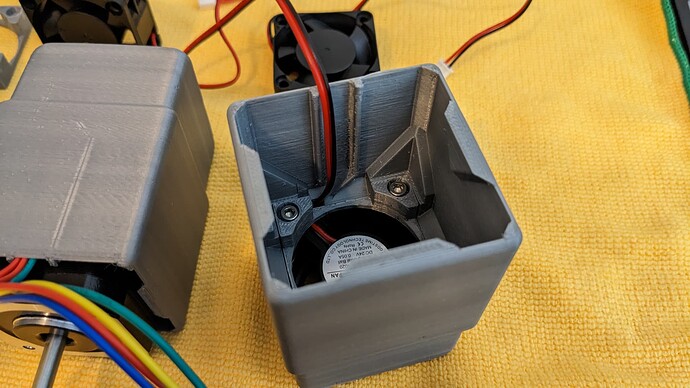

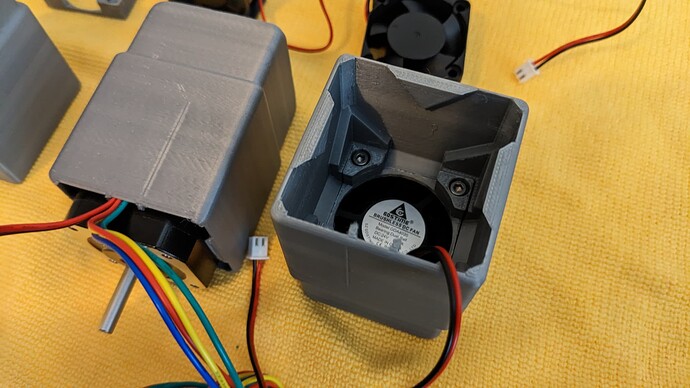

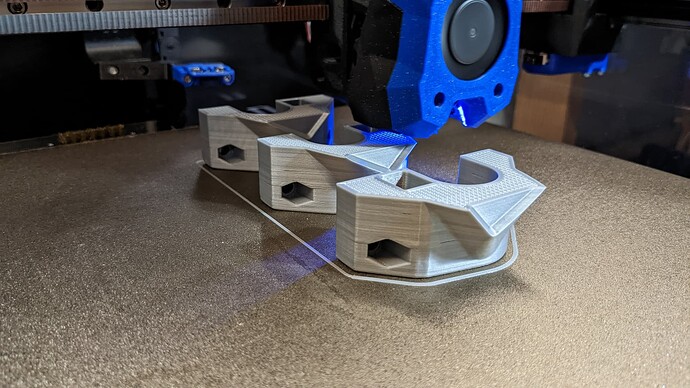

I’ve purchase 4 rolls of silver Spata3D PLA+, and while I haven’t yet tuned the printer for speed I have for PLA and started churning out printed parts. As I have a habit of over engineering, I am printing at 51% Gyroid infill as it’s supposedly the strongest for stressed parts from all directions. However, it is adding hours onto each part, so expecting a couple of weeks worth of printing ahead.

I went with silver filament for all parts, to match the look of the stainless pipe, which will be a contrast to the teal colour of the Makita router.

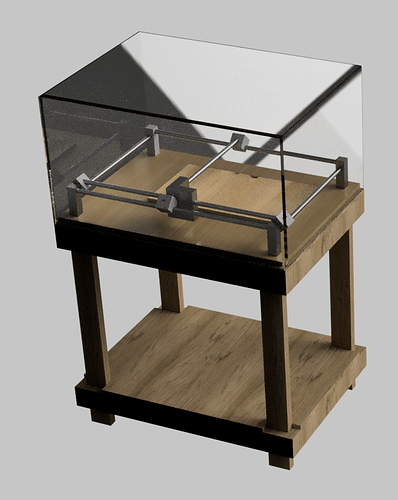

I plan to mostly cut wood with some experimentation on metals, so I plan to build an enclosure with air to clear the chips, and vacuum around the outside edge to keep clear… will see how that works.

I’m sure it won’t look identical to this but this is the kind of thing I’m going for.

I’ve just reassembled my machine (23.5 - pre burly) and am going with Klipper as well.

I’ve just reassembled my machine (23.5 - pre burly) and am going with Klipper as well.