I did it 2.75 times:grinning:

I only printed it twice…

I slept though most of it so no problem

Slept through one, worked through the other.

I saw all the failure pics and got nervous. So I printed it at 85% of 40mm/s and laid awake in bed sweating…But the wife kept checking on it so that was probably what did it.

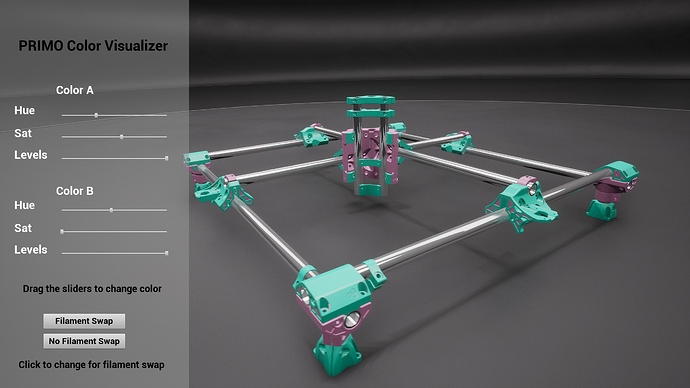

Ok, if anyone cares to play around with it, the unofficial Primo Color Picker App is done to the point its going to be (now with added filament swap options).

It’s a zipped windows executable (465MB - not for the faint of heart) you can download from my google drive. Download, unzip, open the folder, launch PrimoColorPicker.exe

https://drive.google.com/file/d/1TOb_xfjjQ9rQ3lEAj2VUsmHlmIrZhPO3/view?usp=sharing

That is too cool!

Well I printed 15 or 20 of those dang things and have been printing production on it since release…sometimes I can’t believe you guys think I know what I am doing.

That’s a lot of filament!!!

I agree. I had them sitting around thinking I could do something with them. Every time I looked at them I kept thinking about all the wasted time and filament so I tossed them out yesterday.

Best tube cut experience I’ve had was by using a hacksaw and a steerer tube cutting guide on a mountain bike fork.

This time I ordered cut ss tube from metals depot. I’m hoping the cutter person sets a guide/fence once for all same-length pieces!

You need one of those plastic recycler/extruder thingys.

Can’t wait for that and a pellet extruder. They seem to be getting pretty close with them.

The ones I have seen don’t produce consistent filament thickness yet; but its going to be amazing once we get that down!

How the frig do they make filament to begin with? The technology exists… They just don’t want to share

What is the max weight for a spindle on the primo? Looking at water cooled spindles or air cooled

There is a Youtube video of a MPCNC (Not Primo) running a 2,2 KW watercooled spindle.

I personally think putting a water cooled spindle on is less than optimal. The extra weight requires slower movements, especially starting and stopping movement, which wipes out any gain you would get for having a stronger motor. The DW660 has plenty of power at the speeds we move and is a very good match for the rigidity of the MPCNC. No need to go to the extra expense.

Naa, it’s all out there. Getting the equipment to make good filament is expensive.

I am considering adding end stops to my upgrade. In the shop, Mostly Printed CNC’ there are 2 different types listed, end stops and roller end stops. Is there a preferred, one over the other? The roller is listed as a little cheaper. I think that they both have some advantages.

Either will work. Get a few extras. I usually end up snagging the lever and breaking it off the switch.