According to PrusaSlicer at default “0.20mm QUALITY” settings, with the core at 70% infill:

- Gyroid: 420g

- Rectilinear: 452g

This tells me that Gyroid at the same infill % uses less filament than Rectilinear.

According to PrusaSlicer at default “0.20mm QUALITY” settings, with the core at 70% infill:

This tells me that Gyroid at the same infill % uses less filament than Rectilinear.

What spindle did you order?

My field is being discussed! excitement attempted to get under control

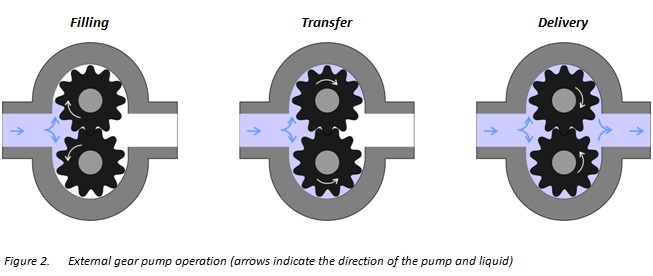

All jokes aside the thing you two are talking about is called a gear pump. You put an extruder on the back side of it to melt the plastic and provide pressure to the gears in the pump. The gears are 2 intermeshing gears that sit in a housing with fairly tight tolerances all around. The gears spin to move the plastic around the outside of the housing and since the volume of the space between the gear teeth and the walls of the housing is very controlled you can very very precisely control the flow of the plastic by changing the flow rate of the gears. So really the extruder is mostly just there to provide heat and push the plastic to the back of the gears.

Trying to include a picture here:

I only explained the external gear pump because I think it’s easier to visualize. The internal one is almost like a Wankel Engine with off center movement around. Same concept though, just inverse.

That makes me feel a lot better about the weight issue. Stronger and weighs a little less at the same infill %.

Pretty sure there won’t be any frowning here, especially considering that you’re actually printing parts! Most important thing is that you get it working.

The consensus is that the actual cutting and dust collection make more noise than the tool, but I got a proper dust collector and used a 611 on my second mpcnc, and the noise difference is remarkable. I wonder how the power difference of an 800w spindle stacks up to the 660w dewalt, being different manufacturers and all.

Remember, part of the reason so many things work at all is BECAUSE Ryan designed it to be flexible and adaptable. That’s partly the POINT. The more I think about it, the more incredible it really is.

Can you share specs and photos of your setup? I’m in the process planning a new build right now so I’d like to get your take.

First-time build squad, reporting in!

Got my pipes - 25.6(!)mm SS from Jegs[dot]com. (Btw, the forum is only allowing me one image since I’m a new user [and no links! hence the [dot]com above and broken URL below], so for those interested, here’s the URL for the pic of the pipes I tried to embed here: https ://forum.v1e.com/uploads/short-url/sRwP3AhUQzJJkHrEJpzFldoBG4D.jpeg)

Also got most of my printed parts:

And the 660 arrives on Friday! I’m beyond excited.

Just waiting for that hardware kit to drop…

I ordered this one: https://www.aliexpress.com/item/32696148057.html

It is 800W with 65mm diameter. The 1.2kW spindle is 80mm and I assume a bit heavier. I searched the forum and have seen some people use a 500W aircooled spindle and some up to a 2.2kW water cooled one - so I came to the conclusion that this one is a good compromise between weight and power.

You still need the power supply VFD?), water pump, and collets for that one very pricey. I have a solid 55mm air cooled version linked on the parts page.

Thanks Ryan, I ordered the matching VFD from the same shop 110V 400Hz output with 110V 50Hz input. Actually it was the only one I found that had a version that supported 100V input.

I am just on a - maybe futile - quest to reduce the noise of the machine wherever I can. My ShopVac is already enclosed in a box with sound proofing materials. And the new Primo will end up on a space that will fit under my rollable workbench. And I will try hang a heavy sound proofing curtain around it once everything is working to reduce the dentist sound.

Was that Jegs brand or All star brand they sell on their website?

I ordered 8x8’ of the Jegs brand. They seem fine, and arrived fast.

i already have the EMT, but i also kinda want to go ahead and buy the 1" stuff and start printing now.

In general, spindles are only quieter while not cutting.

Good to hear. So the OD is within 25.4mm ballpark? (Except the ground weld line)

huh. looks like all star.

hadn’t unwrapped yet.

25.46 OD with ~2 wall.

give or take (crappy caliper)

Got my pipes - 25.6(!)mm SS from Jegs

Did it work with the 25.4 version? I only have access to 25.6mm tubes (~1.5mm thickness) and am afraid it might be too big…

My primo is a black / blue color scheme (but I printed my nut traps in red)…

Shhhhhhh

all star