Dang, how did you do that so well without CAD? Slicer magic?

I hope the answer is a ruler.

Slicer magic!

I am glad it was not a ruler, I would have felt so lazy!!!

My calipers don’t get that big…

Primo Core Test.zip (6.5 KB)

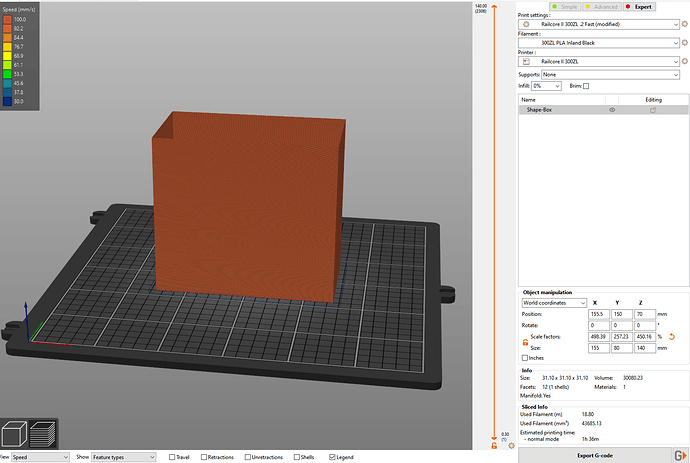

What do you think. Print vase mode, no tops or bottoms. That allows you to slap a tape measure through the middle and check the diagonals. They should be equal and

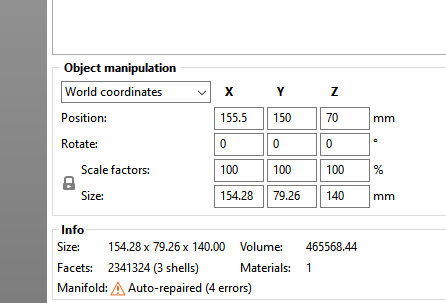

208.87mm x 161.25mm

I print most of my calibration cubes in vase mode. Makes good small screw holders when I taking things apart.

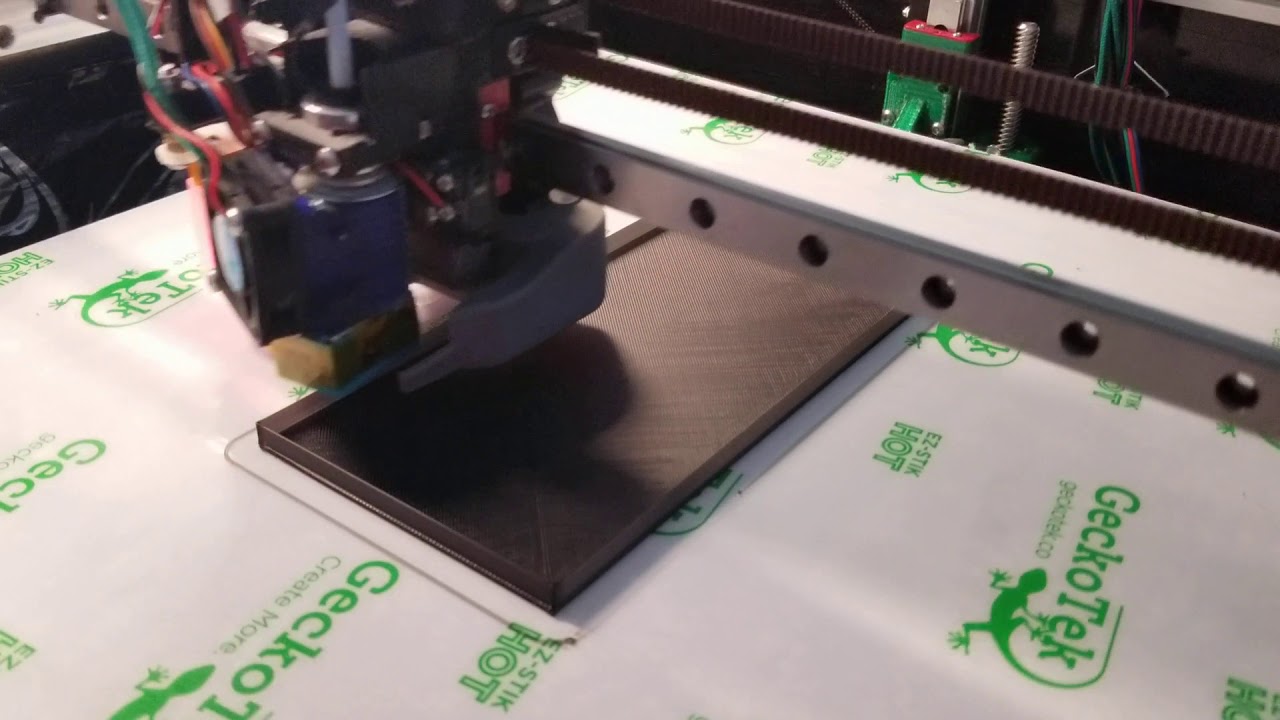

I’m already printing a test vase. Has to have a bottom. No way it will stick without that.

Brim? Hard to measure accurately on the outside of it

Diagonals on the bottom.

I think this is actually almost a necessity for a self printed Core. No amount of adjustments can compensate for a crooked print. And we all know almost zero people have ever checked anything beyond “does my axis move 10mm”.

I have a feeling we are going to discover that a majority of all printers have a wonky Perpendicularity on one or more axis.

It has rounded corners so there are no bulges or ringing from acceleration.

Fancy! I just had prusaslicer make me a box…

My printer’s datasheet says 18x18x18cm. Should be fine.

Cant you just print a regular core with 0% infill?

I don’t want to know  my primo is working great so far. If I don’t lift the feet with a tool length measure to often I’ll be ok have done this 3 time in the last week and you cant get a flat bottom with 1 or 2 legs a different length

my primo is working great so far. If I don’t lift the feet with a tool length measure to often I’ll be ok have done this 3 time in the last week and you cant get a flat bottom with 1 or 2 legs a different length

I don’t think so. Too many bridges with the bolt holes.

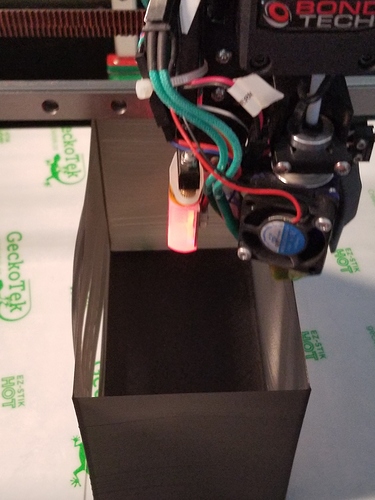

Okay, I think with the tall flat walls that we need some infill.

The front is bowing in as well.

Actually, all four sides are bowing in.

I restarted that print and about two hours in it failed again with a shift in the y axis. Shut it down and started looking for issues, turns out the heat sink on the driver for the y axis was barely attached. My guess is the driver overheated and shut down. Now to wait on some thermal paste.