Nice, I went light grey and red instead

Most 3d printers can easily be adapted to use either. I haven’t done the modification myself, but iirc its just a new heat break, nozzle, and heatsink (since those are sized for your filament size), though that is assuming your extruder can be adjusted that wide (you might need a new extruder).

Might be less hassle to sell it. Although, it does look like that stuff is marginally cheaper a lot of the time. Not so much selection, though. Now you got me thinking. I’m gonna build another printer and use my ender 3 for all functional/quick prints in pla. Maybe he should just get a dual z and a direct drive with 3mm filament, and I can just run whatever color I can find…

Funny, I was thinking that I’d eventually build an extruder for the MPCNC with a 1.0mm nozzle, and a 2.85 Volcano to feed it. Use the big machine for the big, coarse prints.

Need to build an MPCNC first, of course.

I got rid of my 2.85 mm printers because filament selection, variety, and availability is terrible. This is because there are only a small handful of printers that still use 2.85 mm, so manufacturers and vendors don’t tend to worry about supporting them. Right now it’s easier to get (and cheaper) because so much 1.75 mm is sold out; but thats not generally the case.

Check out Dui’s build:

He has made some amazing (and huge) prints with his. It is not for everybody, but with the right amount of patience and knowledge, it can clearly make some great results. I often encourage people to avoid it if they don’t have a 3D printer, or they are hoping for creatily-like projects, but for making huge prints with a big fat nozzle, it is more than possible.

After perusing the Dui’s thread I told my wife I’m going to make a large scale 3d printer… she gave me this look  and said, “So your fail pile can get bigger?”

and said, “So your fail pile can get bigger?”

I took that as an approval to proceed. I’ve got the filament now, why not build the machine!

How do I like this comment more?

The understanding of a wife

For the uninitiated, understanding != support/concern/enthusiasm… at all.

Summary

In fact, you probably get more of one without the other. When they don’t know what the heck you’re doing, they try to support you. Once they figure it out (note the comment about the fail pile), you get eye rolls and resigned sighs.

I’m going to get a toaster oven so I can turn my fail piles into plastic blocks to CNC. It’s a win-win!

Use plenty of air! Don’t want it melting.

I just built a highly temperature controlled toaster oven for reflowing circuit boards. What’s the ideal temperature for casting PLA ingots?

I would assume it was similar to extrusion, although that is still forming it through the nozzle. Do you need some kind of presd to smoosh it flat, or are we assuming gravity will do it?

I haven’t tried it yet, but I’m planning to start at the lower end (180C) and work from there, following the same general approach people use for HDPE (i.e., heat until soft, fold, repeat, and eventually compress into a block.)

It turns out annealing PLA is a thing, so it’s worth thinking about cooling, as well. (though, if you’re planning on machining it, you probably want it annealed?)

For machining, it won’t matter.

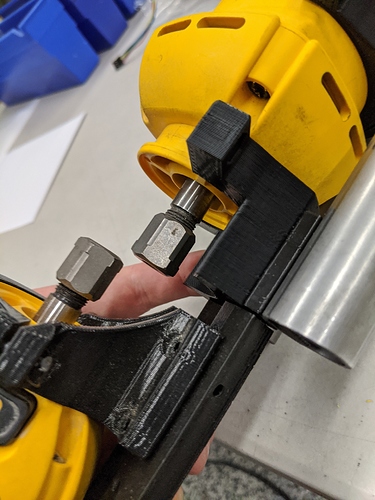

Okay, knowing that each individual change I made probably has a pretty small impact in overall machine rigidity I had to change everything to add them all together and have something substantial.

I think this change alone, even if nothing else is better, should be significant.

Because we can tuck behind the universal mounts.

Spoke too soon, looks like it needs 5mm or so. Bummmmmer

Should still leave it 7-8mm closer than it was. Pretty solid win still.

Those are some sexy looking curves at the top of the Z axis, even if you are trying to hide them behind a power cord.

I kind of like the current monolithic mounting plate. It seems like it provides a little more stability, even if it does increase the internal stress (assuming it’s “correcting” a misaligned hole or two). This seems like it will require a more precise placement of the mounting holes. But that’s just me being lazy…