Did you use the up to date models, or have you got the files from right after the release? There was a misalignment that was corrected, this was last summer.

I seem to have this issue as well. one set of clamps the rail is pretty good and the other has a fair amount of play. even after tightening the core clamps to the core a bit more and messing with the tension bolt. Im using the 23.5mm files that were uploaded the end of august.

I ordered the printed parts a week or so ago from here so I would assume they are the current version.

Yes, they should indeed be. I’m not sure of other options. Sometimes things straighten out when they are used for a while.

There are some clamps that are made to compensate for the early error, but I’m not sure which version and when these came out, sorry to say.

Ive looked around and seen that and that seems to be for the 25mm versions. The 23.5mm version fikes havent been updated at all since their initial upload, on thingiverse at least.

Maybe the 23.5mm version never had this specific error to begin with? I remember that talk of this error occured when European users got hands on the 25mm version.

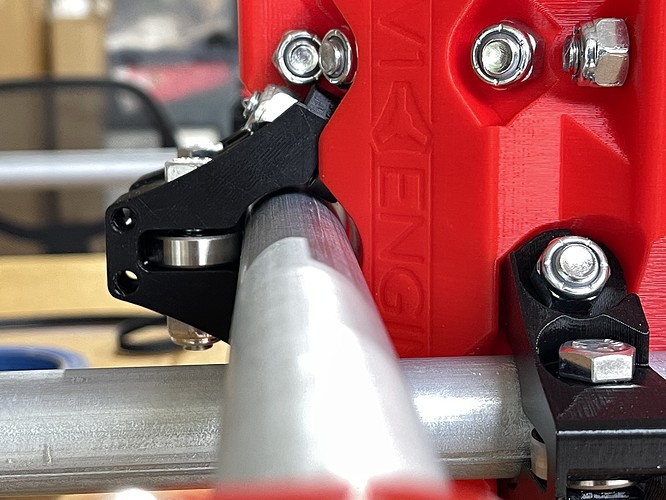

Yeah I assume so but I still have a decent wobble when the gantries are stable and I push or pull the core in either direction. not all the core clamp bearings make contact,

For what it is worth. I have the 25.4mm Version “J”

If you bought the parts from Ryan it is not the parts.

Yep. That’s why I didn’t print them myself. I am sure it’s an error on my part but I can’t figure it out. I am hesitant to start clamping down on the nuts.

Are the pipes straight and even (round)? It’s surprising to see how lousy the quality of stuff is, when you start to look closer…

On a related note, working out a similar issue on my primo I realized the procedure for tightening could be slightly modified to help this. The bolts that hold to the core have some finite slop. So if you tighten those first and the bearing happens to lock in to a loose position, it won’t move much when you tighten the outer bearing/clamp bolt.

To compensate for that, I snugged the clamping bolt first, then tightened the core bolts while holding their heads toward the pipe, then backed off and retensioned the clamp bolt. This sets the core bolts tighter against the pipe, making the clamp bolt much more effective at securing the core.

Anyone else observe this? This is with parts printed a few months ago from the primo J tv page.

[edit: On a side note… the core clamp material is under a lot of stress (by design) and it’s dimensions are very critical to alignment and positioning. Given the cross sectional area of the clamps, combined with the heightened stress, we are likely seeing a lot of creep in these parts. This should be a primary target for folks looking to perhaps cut some aluminum parts for their mpcnc. It also makes it where designing in some bit of preload is not a bad idea. Heck, might even be reasonable to have clamp versions for older cores that may have worn in/creeped core bearing holes.

I had this problem. My pipes aren’t perfectly round. I found if I rotated the pipe a few degrees tightened up.

I haven’t mic’d them but the same tube is snug on the x gantry clamps but loose in the y side. I am going to try truglodite’s suggestion and see if it helps.

I’ve just started my assembly and notice this as well - the trucks, rails, and feet are all solid, but the core can wiggle in both the X and Y clamps.

I will try Kev’s suggestion and see if the core bearings can be seated closer to the tubes.

I have that same issue. Part of my issue is I think my cross tubes are slightly bent. At some points along the axis it’s nice and tight, and at other spots it’s loose.

I used DOM tubing I bought from Jegs and they came in slightly warped. I’m thinking about getting SS tubing.

Did you find a solution to your problem?

I was having this exact same issue on my Primo that I just assembled. I followed Kevs Solution, and that fixed the issue for me!

omg dude. You absolutely saved me! my tubes have a rough average diameter of 24.7mm… when i followed the v1 instructions to the T… i had really loose sloppy rails! nipping up the outer bearing first before tightening the inner 2 has completely fixed my issue! its smooth as a nuns nunny now… so thank you very much, im on my second set of bearings now and i reprinted the core and clamps because i was sure id ruined mine with overtightening stuff while figuring out the issue only for the new core and bearings to have the same issue! wish id have found this sooner ![]()

Had the same issue with the J series core clamps on 25.4mm straight tube. Using Kev’s method solved my problem also. Thanks @truglodite