This is history in the making! This printer really seem like “next gen”, while being affordable and accessible for a DIY crowd. The thought of coming over to test out tpu hammers is making me smile

I have a back to back test print coming off in about 40 minutes. I will put up a picture.

Tangent…I just got an email from one of my professors from years back. Looks like a solar collector/concentrator I designed should be ( ) getting mounted to roof of the new engineering building at SDSU. How freaking cool is that!

) getting mounted to roof of the new engineering building at SDSU. How freaking cool is that!

And you say this can all be built in a wood frame instead of Al extrusion?

<mr_burns>Excellent…</mr_burns>

Absolutely

Hard to take pictures of this stuff. Subtle ripples are gone, same parts in the sun and in led lighting.

Getting there!

Personally, I would have been quite happy with the first ones! But the new ones are even better! I just read through this entire thread last night and have to say how impressed I am with your design process and relative speed that you have created this thing in. My (simple) projects take much longer for some reason

Thanks!

When I am having fun and making progress I get a little obsessed. I caught myself getting irritated when orders would come in because I would have to stop to pack and ship.

That isn’t good. So now I do both at the same time. One order one printer thing, etc.

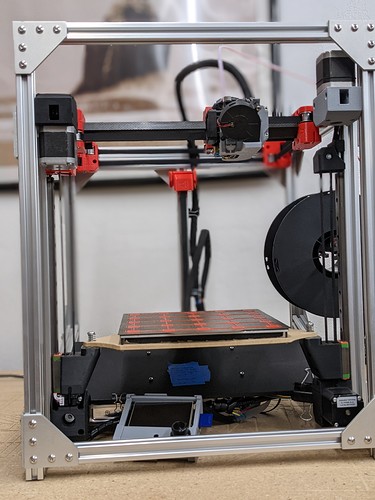

20mm CF tube is in customs (Hopefully for less time than my last V1 order) The 300mm Z MGN12 linears are en route too. 310X310mm heated bed with magnetic build plate is already here.

Can’t wait to start printing/cutting parts for this!

Well, it’s getting real close.

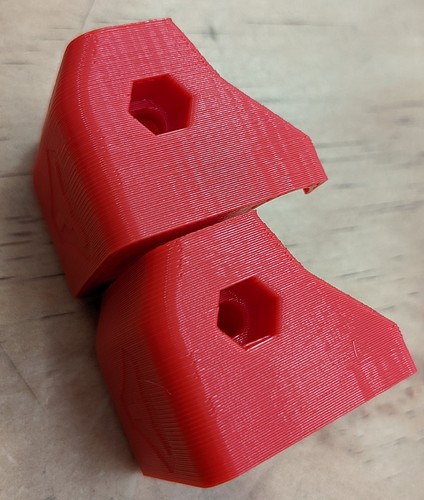

Some minor tweaks on the Z sliders, and try to make the stepper mounts look a bit fancier. Functionality…I am very happy as is. I am just trying to make it look a bit more interesting and work in wire routing.

The new Hub (center) is feeling really good.

I have some wire routing ideas. That Hemera fan mount is fugly.

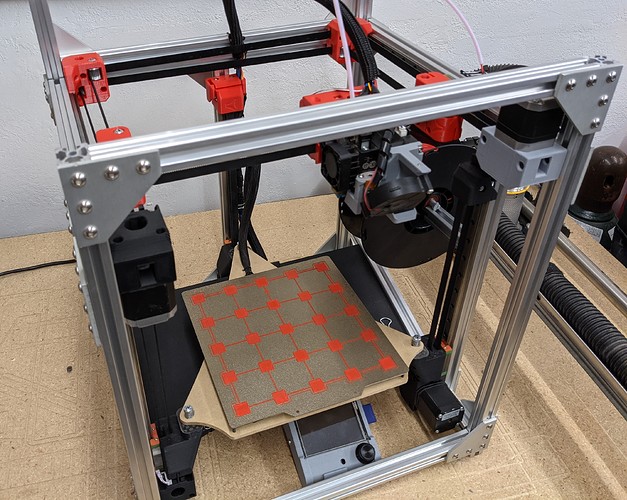

That leveling print on the bed was from this morning and the new Hub. It is by far teh best I have ever done. 200mmx200mm and flawless as far as I am concerned. Autolevel and bilinear leveling take a considerable amount of time but I think being able to use the entire plate will offset the time lost. The steel bed I have on it is larger than my heated bed, that is why it might not look like 200x200.

I do like the 5015 fans though, I have a bunch of them because they’re very effective and reasonably quiet air movers.

I was thinking that I’d do a Bowden setup for this, but I’ve been looking at those Hemera extruders, and really, I’ve never had much luck with the Bowdens myself, so I’ll likely go that way. More stuff to buy, but if this ends up taking over as my main printer (Which it looks like it will) then it’ll be well worth it.

You’re going to need to put the SKR Pro with 6 drivers back in the store though!

Okay, this is just way too much fun. Time to re run the tuning tests. This print is flawless other than slicer stuff like coasting and retract. At 42mm/s there is zero ringing now. I am going to ramp it back up. Volumetric from the Hemera says 52mm/s with the same settings should work. Slicing now.

Keeping the fan, just ditching the angle.

I think a Bowden with linear advance would work pretty good these days. Or those remote drives we talked about earlier. This would be a fun platform to run some comparisons.

Yeah 6 drivers, I have spares for sale. I will look into it.

Or being able to add one extra (like you do with belt) to the order.

Well…25% faster, 52mm/s .32mm layers (10mm^3). This is like 99% as good as the last. Slight hint of an accel bulge on the logo. I am confident I can tune that out now with Teaching Tech’s tools. This is the max recommended by E3D for this hot end, but they are clearly being conservative.

For now I will focus on the hardware again. I have a stepper mount ready to print. Might add a little decorative touch first.

I like my Milwaukee m12 brushless drill. It is compact, and all of the electronics are potted. When I get the head too hot, I can turn it upside down in a bucket of water, and run it till the vented water is cooler. The last time it got hot I had put 4 holes in a 4x4 Pressure treated post with a dull spade bit. The Milwaukee batteries are expensive, so I now run aftermarket ones since the original ones died after 8 years.

That would feel crazy to dunk my tools in water…on purpose!

Still need a name.

I am happy with these parts. Next up is work on the wood frame, the extrusion frame is nearly done.

Mostly wooden and printed 3d printer

Mowop 3dp

Mowoap, mostly wooden or aluminum and printed 3d printer… sorry, brain functions are slow, and creativity suffers alongside…

CFXY - Carbon Fiber XY

MPXY- Mostly Printed XY

DeltaXY since the bed movement is similar to a Delta printer

3DXY

CFC- Carbon Fiber Core