The biggest “IF” is that Carbon fiber rail. The linear rails are extremely heavy every mm adds soo much, not the carbon fiber (or maybe even aluminum) including all the motion parts it is so much less moving mass. I know this shows a hemera (worst case), but if it was just a bowden the mass starts to make a larger difference. Will it hold up for long, is if worth the larger dims? I have it built and it is light, rigid as heck, and smooth.

Makes me want to rebuild the zen with one.

Railcore uses a mgn12 rail for the Y rail. I think the hevort and the voron also use them.

If you can swing it, belts for the Z would be better than screws.

X?

That is the part I thought needed to change the most. The bearing block and the CF motion stuff are roughly the same weight. So that leaves the rails. CF=.115g/mm (300mm=34g), Linear is 0.6g/mm (300mm=180g). That linear rail and beaaring block is nearly a standard bed (220x220 Al bed with a pei coating weighs 430g).

A 220mm capable linear X axis with bearings is almost the same exact weight as a bed. So for small prints no real diffence from a bedslinger…why bother.

The second “IF” is Z belts…with no gear reduction. That is how this works as shown. I have talked a few people about this and getting all sorts of info. The largest downside I see is the minimum resolution is 0.01mm with 0.9 degree steppers and 16T pulleys. I don’t think that is an issue. BUT…homing, ABL, and Z baby stepping to get the ultimate first layer might want a bit more than that.

In the end I use a bigger nozzle and am looking for some inexpensive speed. Fun so far but I am just about ready to run a test once that bed mount gets worked out.

Why no gear reduction? You could easily add belts and pulleys to get a better ratio

Well hopefully it isn’t needed. If it is should be an easy swap and I have a ton of small gt2 loops.

Well, guess I’m out, then.

From what I am seeing, Marlin doesn’t actually do 3 Z stepper homing/leveling yet? It has to be reprap firmware or klipper?

I have no idea why I am messing with this so much I should have started messing with the LowRider instead.

Nevermind I found it, “Z_STEPPER_AUTO_ALIGN”

Do you have the RailCore II Barry, or the previous one? That printer is looking great. I swear it looked a bit different last time I saw it.

Railcore II. Same one they had across from us at mrrf last time we were there.

So, uhhhhhhhh, onto the lowrider then?

Nope.

Sorry for lack of updates, been real nuts around here playing nurse.

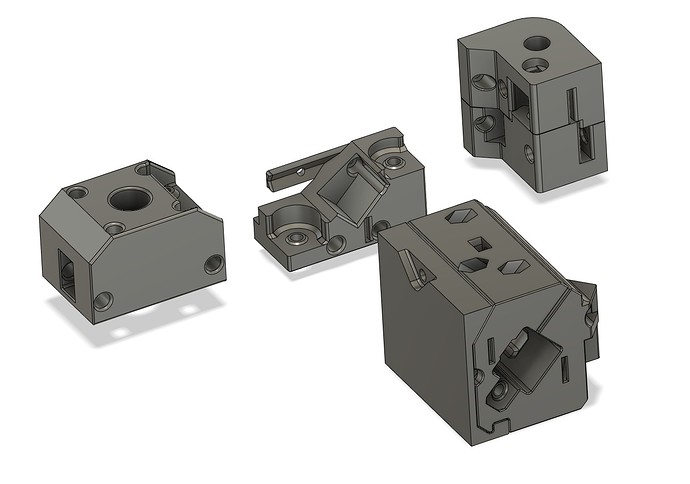

I took the downtime to learn fusion. To learn fusion, I started over and made a new printer assembly. I am A few days further than I was with the old(er) model and it payed off I like this one better…and I am starting to get the hang of Fusion. Makes me want to start over and do it more proper but, I am not much a of glutton for punishment.

I challenged myself to do it with fewer unique parts, so far I think I pulled it off by a lot.

I think the top (XY Axes) uses less hardware that the previous one and 7 unique printed parts including the tool mount (you print multiples of some of them).

I hope to put together a feature complete real set tomorrow evening. If it works out, I will probably share a picture or two.

I want 3 pictures. Go big or go home.

One take it or leave it.

I forgot the fusion assembly is very different as well (translation, slow going). I put together the real parts made a few more edits so I will reprint… but so far so good.

I know it doesn’t show a lot…but that is all the XZ parts. Using belt pieces for triggers, pretty sure I have never seen that before. Feels super smooth. My previous wood box doesn’t fit so I will try to slap together a extrusion frame ASAP, or cut a new frame. To do either it would be best to get the CAD assembly done though.

The tool mount is as simple as it gets, works so good. One screw solid hold, easy to modify. Easy to get off in case of a nasty clog.

Belt anchors and tensioning is working great, super simple, minimal.

Learning a lot.

Here I thought it was just me…

I know my CAD skills are poor, though. I’ve been thinking that I want to give Onshape a serious run. There are things that I’m sure I am doing badly in FreeCAD, or else there are things I want to do that it just doesn’t.