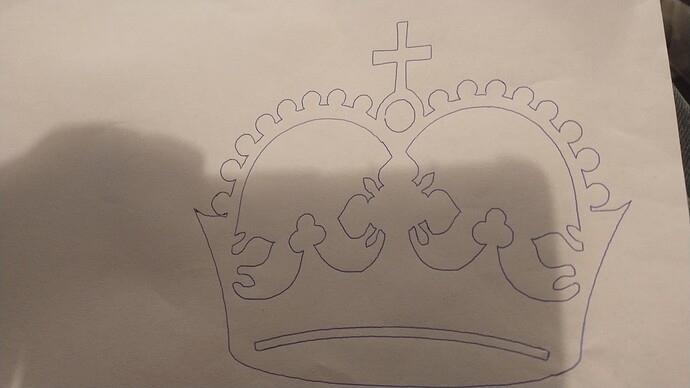

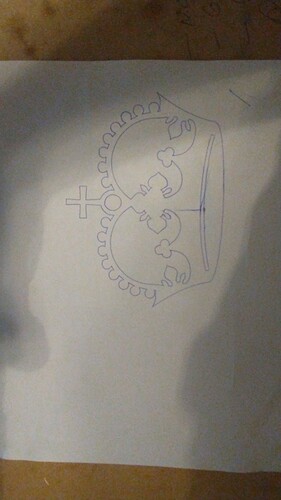

I had my cnc draw this. Pretty amazing when you do something like this.

I’ll send more pictures later. If I don’t get this out of here, my wife is going to sell it to pay a divorce attorney.

hmm, that is not v1 engineering stuff. What have you got there.

Looks like the crown is too tall, steps per mm seem to be off on that axis.

Other than that, congratulations.

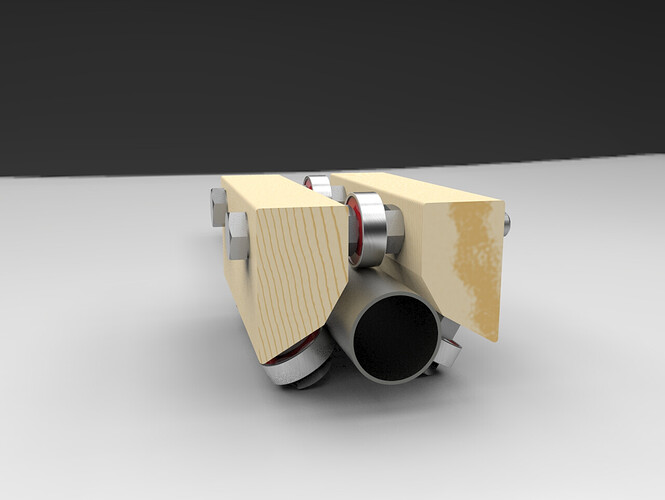

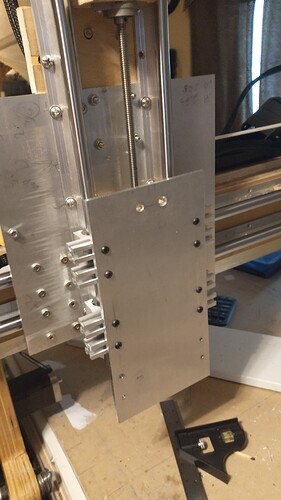

Oh… I see angle aluminum and V groove bearings. I was considering using those on a build I drew up in OnShape at one point. I bought the bearings (Pricey those) and the aluminum. But then had to wait a few months before I could build. By then I completely changed the design (a few times).

Very intriguing machine you have there. Do tell how that goes. I am especially curious to know how the edge of the aluminum will wear over time. Does it flex under a load? How did you get the bearings positioned correctly? Can you adjust tension on one of the bearings?

I also see a NEMA 23 stepper. What are you using to drive that? What will you use the machine for? What are you doing to me? One picture and a no description! This is like lighting brownie scented candle in the house. I smell the goods but I don’t get to eat!

Congrats on the machine. So far it looks great.

I built it with birch wood. I also upgrade the x axis and z axis to linear rails and bearing block. thanks for the reply.

It’s really experimented really. the only aluminum I have on it now is the y axis. i changed x and z axis to linear rails and bearing blocks. The y axis is a strip of 2 inch aluminum. there’s a little wear but that’s the v bearings that rolls on them. I had to readjust the bearing because of the wear. I doesn’t wear anymore.

I am using 548 or something like that. They are external drivers.

I am using that drufelcnc, and it calculates the pulses per mm. It’s not accurate evidently. I had to use it to get it in the ball park. Then fine tuned it. I would make a line x and then y. If one was longer I would bring the readingdown in increments. Its better now. Ineed to do some more fine tunings. the tubes I bought for the lowrider, I am going to ribbit nuts in the bottom of the tubes and bolt them down as the y axis. PUt this on the bottom of the gantry plates and run across the tubes. with this

I really don’t want wood, I may see about aluminum. With this I can put bolts under the tubing about every 10" thanks guysI Upgraded the x and z linear rails.

Interesting, how are you attaching the the bolts to EMT? Welding, or drill keyholes, or something else?