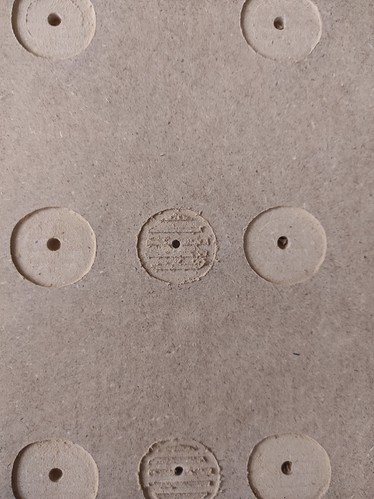

So i have lowrider2 and this was my first job… waste board milling… and the circles are really out of shape… different sizes and shapes… no lose bolts so i have no idea how can i improve that

Share a bunch of pictures of your build, please. Maybe we can spot something like white belts.

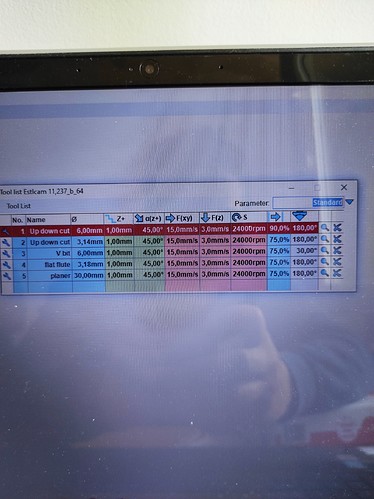

Also share your CAM settings.

Will be posting a video of the build later when i come to the shop but here is the picture from estlcam… i used same settings as on v1 page but thinking that is more for the crown/pen test and the feedrate 15mm/s is to fast… or am i wrong? Also 90% stepover is way to much i think

Yeah I agree stepover could be reduced, and 15mm/s is a little fast but I have gone faster with less deflection than what you are showing.

When I first set up my Lowrider I got results almost identical to that from loose grub screws on the stepper shafts.

Have you tried drawing a big 300mm x 400mmm triangle and then measure the hypotenuse which should be 500mm. I had circularity issues when my machine was not perfectly square. It wouldn’t explain those steps though, those look like grub screws or loose belts.

Also I found a .3mm finishing pass really helps, especially when doing linear pocketing like you are doing

Checking grub screws is my go-to every time I encounter a problem.

With the up/down cut bits the first few mm of cut is forcing all the chips right into the stock. Switch to an upcut bit if you have one until this is figured out. Nevermind the stock tearout until the machine is solid.

Everyone’s machine is different, but a consistent cam setting is something like 20%-40% stepover at 6-10mm/s with a depth of cut at 1x tool diameter up to 4mm.

Circles are quite challenging. A rough cut then finishing cut is advisable. Leave some stock on the rough cut then follow up with one or more finishing passes.

And check the grub screws.

Examined my up/down bits and (depending the characteristics of the tool you have) if your bits are like mine then the first few mm are upcut only. Learned something new.

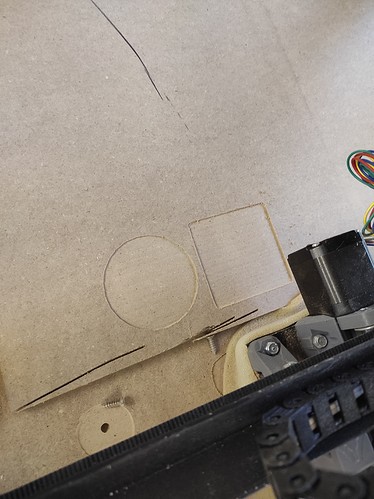

You guys are geniuses… it was the Y axis grub screw.

Now its even better than i expected … need to buy loktite

Nicely done.

I used super glue.