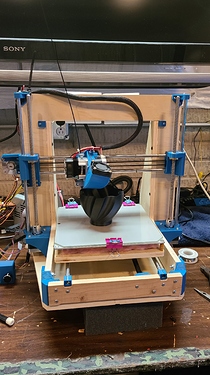

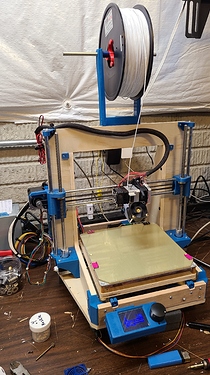

I built this MP3DP a while back

and I have now been on this kick looking to see how fast I can run it. I have posted some other threads, 1, 2, looking for guidance and have now arrived here.

The current incarnation has 84oz/in steppers for the X and Y axes and can print reliably at 150mm/sec.

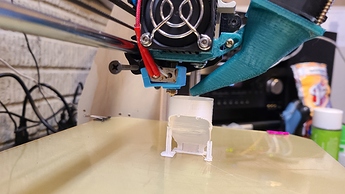

Not the prettiest, but you can tell what it is. This was .2mm layer height, 150mm/sec, 1000mm-sec/2 acceleration.

The first one I tried to print at this speed would not cool fast enough and the bow was all kinds of messed up. As I mentioned in another thread, I had the speed, cooling was now the problem. So I dug through my box-o-fans but couldn’t find anything with enough CFM to cool adequately. So I turned to my favorite online auction site and for a couple bucks a piece I found these…

Nothing short of your louder-than-God rack server fan. 12v, 1.2A, 30CFM. (and they were local so I had them in two days)

When I originally hooked it up (they are stacked but I split the fans so I’m only using one), I didn’t get any rotation until 97% on my fan slider. So I had loud, louder, louderer, and loudest. After some digging around, I found the PWM fan settings in the Marlin Configuration_adv.h. This allowed me to override the min and max PWM control and make everything work right. Here’s the lines from Marlin…

// When first starting the main fan, run it at full speed for the

// given number of milliseconds. This gets the fan spinning reliably

// before setting a PWM value. (Does not work with software PWM for fan on Sanguinololu)

#define FAN_KICKSTART_TIME 500 <-----Uncommented and changed from 100 to 500

/**

- PWM Fan Scaling

- Define the min/max speeds for PWM fans (as set with M106).

- With these options the M106 0-255 value range is scaled to a subset

- to ensure that the fan has enough power to spin, or to run lower

- current fans with higher current. (e.g., 5V/12V fans with 12V/24V)

- Value 0 always turns off the fan.

- Define one or both of these to override the default 0-255 range.

*/

#define FAN_MIN_PWM 245 <--------Uncommented and changed from 0

#define FAN_MAX_PWM 255 <--------Uncommented and changed from 128

This was after a few trial and errors, about 8-10 re-compiles, and of course, getting send errors because I kept forgetting to disconnect RH after testing each time.

Now the fan operates as it should. Although at 75-100% the hot-end heater can’t keep up and I get thermal runaway shutdowns.

But that’ll be another experiment.

But that’ll be another experiment.

Anyway, just thought I’d share thus far and pass on what I learned to anyone who could use it.