Nah, Directlaw is craaaazyyyy good.

Haha, tbh the development of how all that electrical stuff works together was not done by myself, It was developed by the creator of the OpenCNC shield

Since I needed only a few functions on my handheld, I picked the most important ones and integrated them in my drawings.

There was indeed some trial and error during assembly!! (Supplying power and sniffing carefully, you know it)

Time for an update including questions at the end.

Making it short: The dimensions were not accurate after my first tests. Moreover, the wood started smoking often even with rather low RPMs and adequate feeds. I tested several bits (6mm 4-tooth HSS; 3,125mm 2-tooth; 60° carving bit).

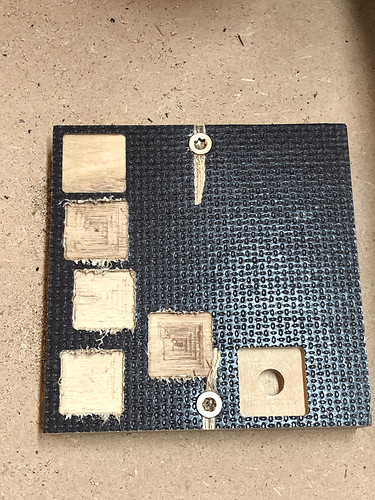

It took me three troubleshooting days checking bolts, belt tension, cutting speeds until I found out that my spindle motor was turning in the wrong direction (counterclockwise). Thats why the dimensions of the squares were not accurate in my first tests and heat built up being responsible for smoke and smell. I was sure, that the machine & step settings were right which was proven by a scratching carving operation with perfect dimensions as a result.

Have a look at my sample piece and compare that crap on the lower left with the nice squares on the top left and bottom right after I corrected spindle turn direction:

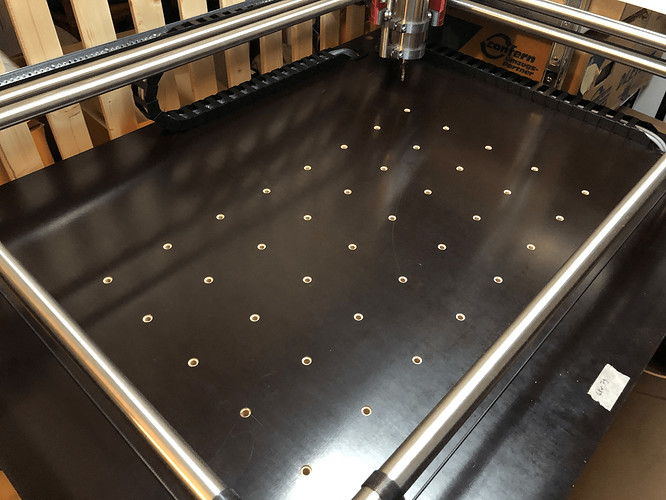

Right away, I prepared the threaded insert holes which was a lot of fun. It went through the wood like butter. I guess it was a feed of 1000mm/min, DOC of 5mm and 14000RPM with a 6mm 4-tooth HSS bit. I had the feeling that I can push it a lot more.

Any advice for the spoil board? MDF has so tiny particles and may be a health hazard (?) which is why I prefer some basic chipboard with bigger particles. What do you think?

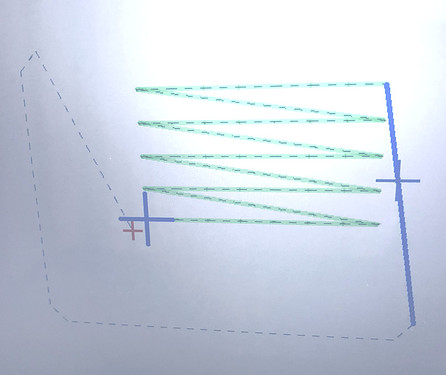

Does anyone know why ESTLCAMs “end path” has those jags? It would move outside of my workspace, so needed to stop it before ramming into the corners.