Hey All,

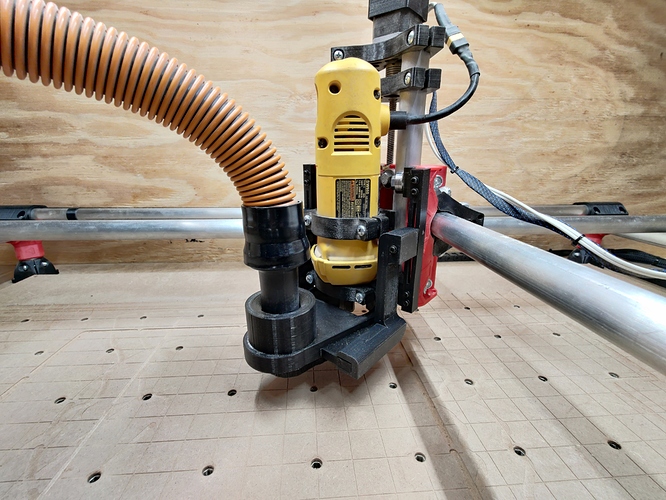

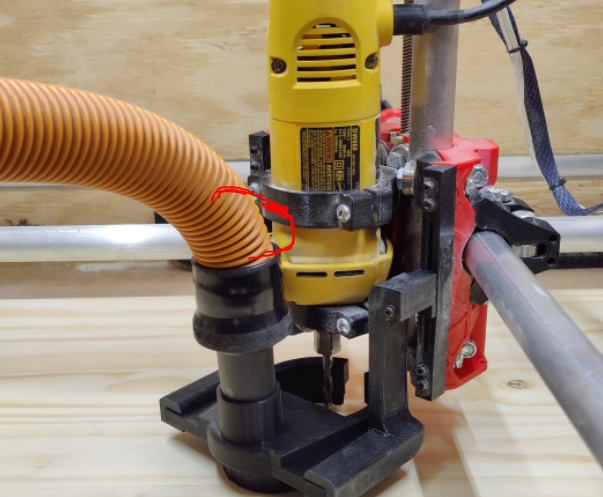

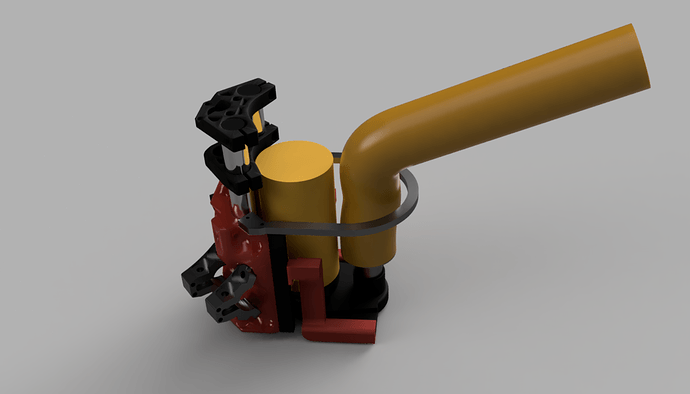

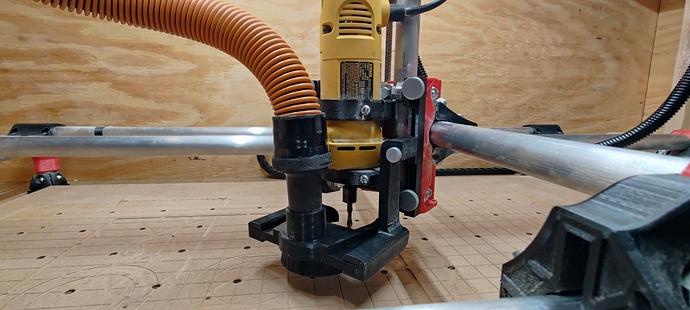

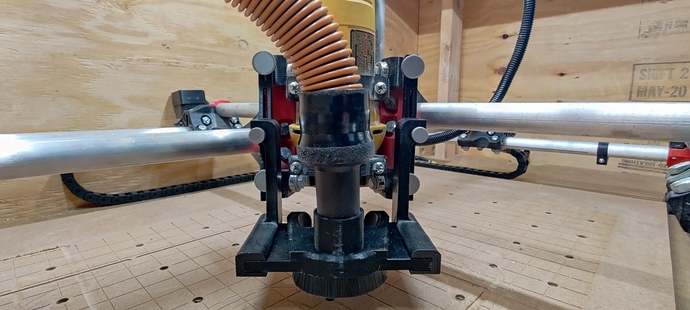

I recently was looking for a decent dust collection system that was Z axis independent.

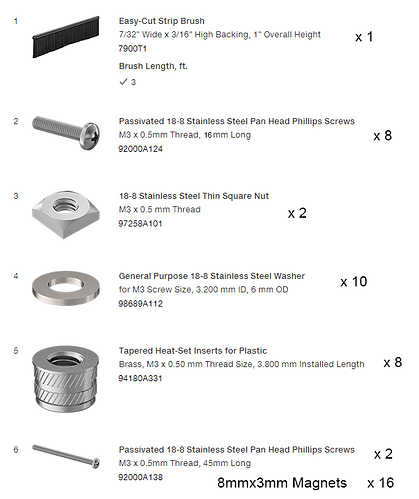

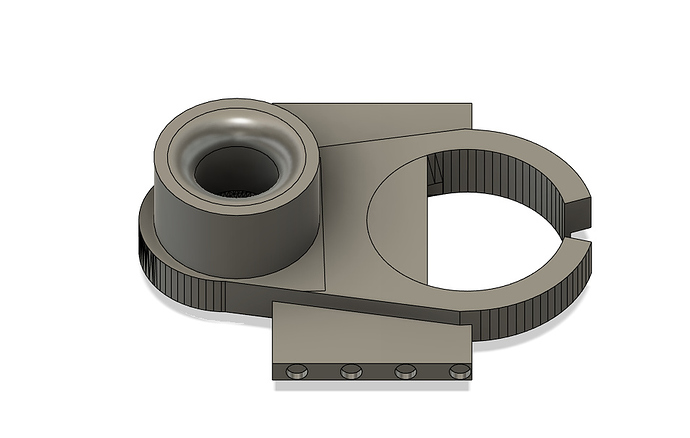

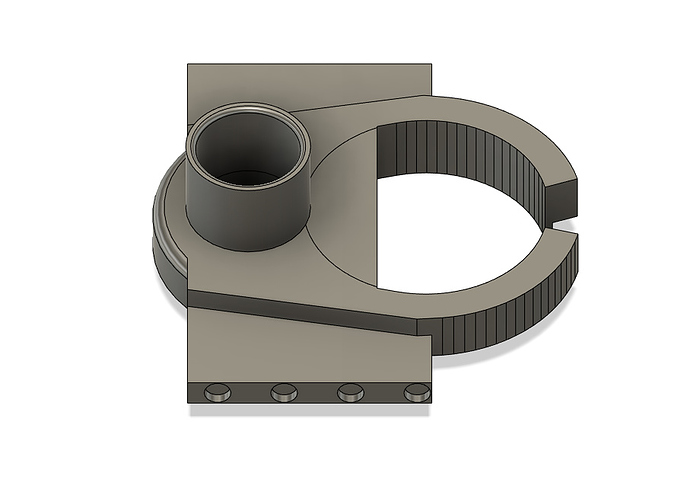

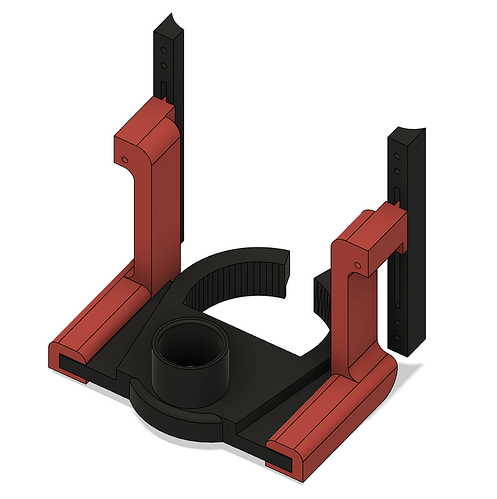

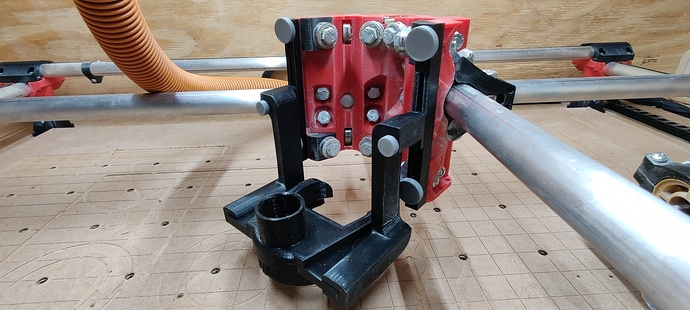

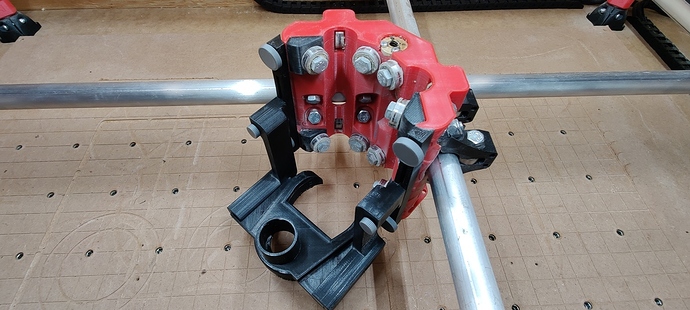

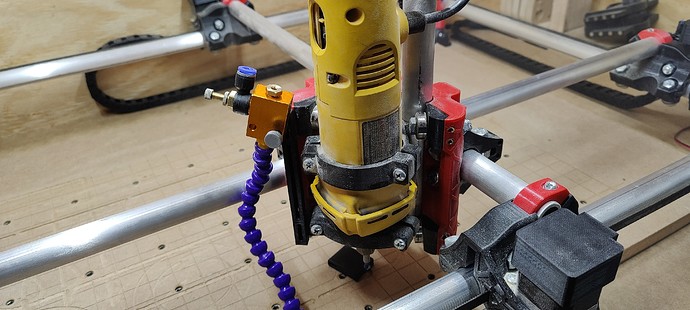

After a bit of digging, I determined I was going to design one up myself. This design allows you to set the height of the dust shoe and lock it in so it doesn’t move when running the CNC. The dust shoe is held in by 8, 8mmx3mm magnets and allows you to easily add / remove the shoe when setting up your work.

DISCLAMER: You will loose about 3inches of X Y cutting area, you will have to adjust endstops to account for this. I am trying to figure out a good way to work around this, if you have any ideas, I’m all ears.

Demonstration Video

Thingiverse Link (STEP File on thingiverse for remix / hose resizes)

My design has two “rails” that attach to the core via M3 Heated Inserts and M3 16mm machine screws. The easiest way to figure out where to place the inserts is to hold the sliders up onto the core and then to take a pick and poke through the 8 holes on the slider to mark on the core where to drill.

Once you have the holes, take off your router. I’d recommend just hand screwing the lead screw and taking the whole Z assembly off the core and setting it a side for now.

Then, take a drill bit that matches the size of the M3 heated inserts and drill into the core at the marked locations from your pick. At this point, we can take our inserts press them in using a soldering iron. I used 300C on my soldering iron to do this.

Next, take the M3 16mm screws and washers and attach the slider to the core.

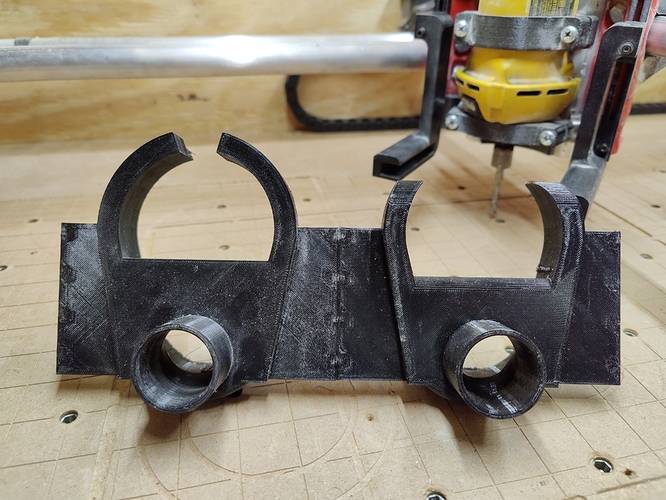

You will want to go ahead and press in the magnets into the arms and dust shoe after attaching the slider to the core. (Make sure your magnets are in the correct orientation)

Once the magnets are in, take the square M3 nut and place it into the slot on the back of the slider rail. Take an arm assembly and an M3 45mm and washer and attach the arm to the core, don’t crank it down. Repeat for the other side.

Finally, take your Easy Cut Strip brush and press it into the dust shoe. At this point, you should be able to slide it into the two arms and test it out.

I ended up cutting 3/4" MDF after attaching this dust collector and I was very impressed with how much it picked up. I’d say it got about 90% of the MDF dust.

Feel free to remix my design, I’m open to suggestions on how I can make this a better system.