There seems to be a lot of print issues these days. I am going to try and find some suitable tests to help prevent a lot of wasted time and plastic.

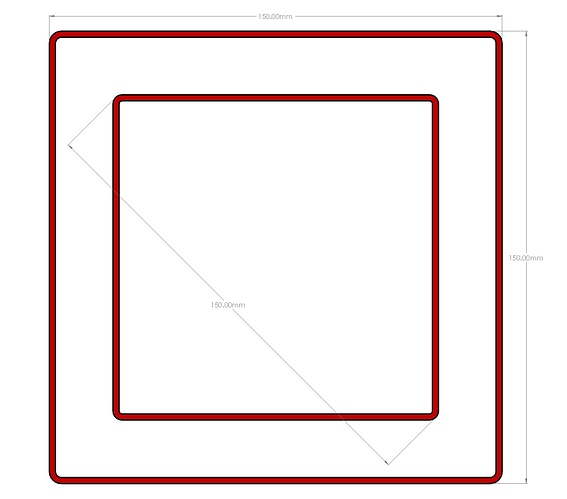

1-XY axis distance and square.

You are looking for 150mm on each side and equal diagonal dimensions.

Possible issues, Measure near the top of the print so you are not dealing with elephants foot.

https://www.prusaprinters.org/prints/36412-xy-size-and-square-calibration-print

If the outer print is not 150mm - <0.6mm+/- loose (or tight) belts can be an issue. If it is >0.6mm+/- off steps per mm should be calibrated.

If the diagonals are not equal - This means your axes are not square to each other. You will need to physically adjust your printer. There is a marlin tweak to adjust skew but you would be best to get it physically as close as possible first.

Notes- Why rounded corners, accelerations can cause bulging and mess with accuracy. Why 150mm, largest size that fits most common calipers.

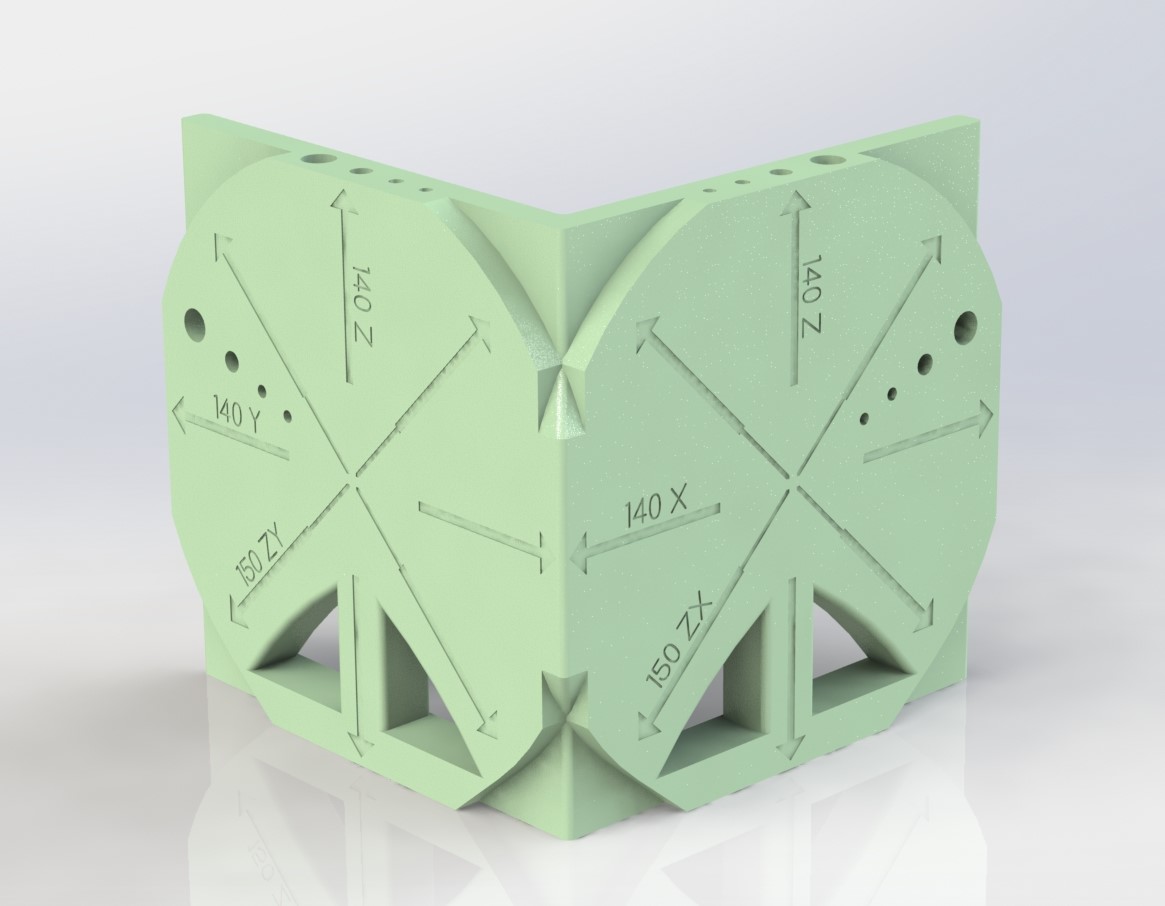

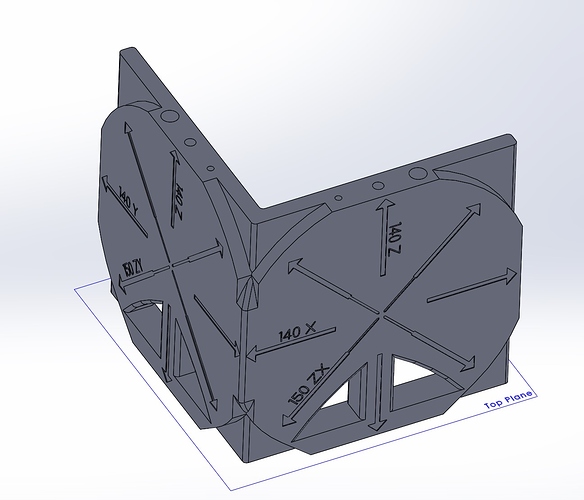

2- ZX and ZY axis distance and square.

This part is mainly made to test a printers frame for axes perpendicularity. If your printer is built without checking you can get odd shaped prints. Parts that need dimensional accuracy depend on a correctly built printer.

XZXY - main test part.

The Z dimension should be within 0.5mm. Ideally it should be within less than half your first layer thickness, to account for some layer squish.

The diagonal dimensions should be within 0.6mm. This is the meat of this test part. Note; On a Cartesian style build if you find ZY issues you should print a test part on each side of the bed to check both sides of the frame (or Z rails on a Z axis bed build).

The holes are fairly V1 Engineering specific, 8.2mm for bolt holes, 5.2mm for M5 screw holes, 3.4mm for loose M3 screws, 3mm for M3 screw threaded holes. Just a gauge really.

The overhang test should be easy, if not your print temps or print fan is off. These need to work for a V1 Design to print well.

Ghosting of the logo of other designs in the part means you are printing to fast of have harsh accelerations. Good rule of thumb is to see no more than three very subtle ghosts preferably less, any more and you really need to work on that.

https://www.prusaprinters.org/prints/38846-zx-and-zy-printer-frame-test