I will check the fuse tomorow by removing it from ther place i have the little one spair

i am not shure i will keep the marlin 1cnc rambo dual because i like more to use dual z and dual x and dual y plus the toutch probe pressure disk !

if i can make it run i will be able ttest other firmware after to see whitch will be the best for me

i just check the 3 fiuse they are all good

i will come crazy whit this

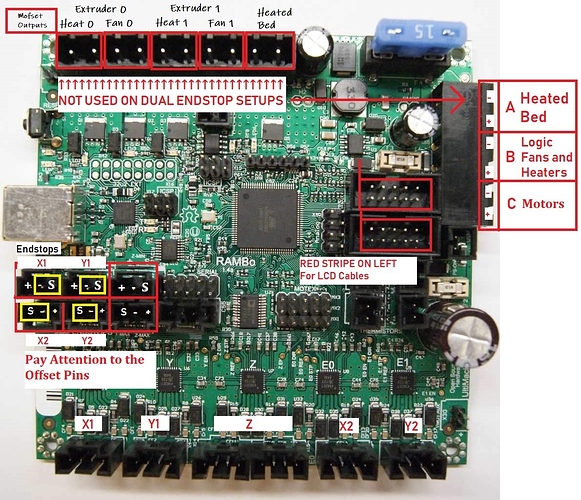

The Z2 looks like it is connected to the wrong port. There are two labelled Z, but they are wired in parallel. You either want them in series or separate drivers. The X2 should be in E0 and the Z2 should be in E1.

You’ve said none of the motors move. You also show a screen with the halted message. What exactly did you try, what did you expect, and then what happened?

Disconnect the endstops for now. We can figure out homing later.

This board is black. So I’m guessing it isn’t from ultimachine. Where is it from?

Hi Jeffeb3

the board is from amazon

https://www.amazon.ca/-/fr/gp/product/B087CN9QVV/ref=ppx_yo_dt_b_asin_title_o08_s00?ie=UTF8&psc=1

i will need to connect the 2 Z whit the cable i buy from v1engineeringbut connect on one of the 2 connecter for the halted pics i tried homing all !

card from amazon is Vaorwne Rambo 1.4 Carte mère Rambo V1.4 Méga et pas à pas à pas pour imprimante 3D Lulzbot Taz6

i build the version Lowrider2 cnc whit 25.4mm tube https://www.thingiverse.com/thing:3026040

it is not clear for the firmware to used whit this machine whit rambo 1.4 i think i should change the board and screen

there is 1 thing i dont understand i am confused i have 3 axes X Y Z

if i am in the front of the machine from picture

X = 1 stepper motor left to right 1 belt

Y = front to rear 2 stepper 2 belt

Z = 2 stepper whith 2 screw

you say X2 in E0 but i have only one X !

i thing my post is confusing people i used eather v1cnc rambo dual but i think i have the wrong firmware

everywhere in vidéo i see mpcnc for my machine not v1cnc but the problem is i dont see any configuration on mpcnc whit rambo 1.4 should i change board and screen ?

sorry for the mess on table i just finish assembly everithing !

i used this setup to plug my board

I’m getting super confused. I think some of it is just the difficulty reading. I am not the most careful when I’m writing here, but I am really having trouble understanding you. Sorry. It would really help to focus on one problem at a time, and just answer these questions explicitly:

- What did you do?

- What did you expect the machine to do?

- What did the machine actually do?

On the low rider, you can make the X or Y the double axis. If you were standing on your couch, it would look like you had 2 X and only one Y. I switch back and forth because I do not have my machine oriented the same way as the docs. If I say X2, just pretend I said Y2.

The firmware has it coded that the bed size is 200x200. So if it has to move more than 200mm, it will print that error. Let’s ignore homing for now and focus just on getting the motors to move the right way.

I think what you’re saying here is that you have a serial wiring kit from Ryan. No. Don’t use a serial wiring kit (if you have one), instead, wire the second Z motor to the E1 port.

Wire the second Y motor to the E0 port.

Don’t try to home anything. Disconnect the endstops and focus on getting all the motors to move when you jog them from the screen.

This firmware:

But that is configured for dual X and dual Y. You want Dual Y and single X, and 2 Z drivers. You will need to change the configuration_adv.h file for Dual Y and not Dual X and set the number of Z motors to 2.

sorry if you are confused i am french and i try to do my best to explain !

i just understand how to reply on the post i think

as i say from previous from this picture this pics i am in front of the cnc for the explain we have to understand first to get the information right

from my understanding the X axes it the one who moove from left to right so i need 1 X only for this one

and the Z axes is the 2 stepper whit the 2 screw one each side who is lifting the dewalt up and down on the table so i need 2 Z axes 1 left and 1 right

and the Y axes is the 2 axes driven by belt each side of the table so i need 2 Y 1 left and 1 right

is it more clear like this ?

so it means if my table have a 48inchx48inch i will have to change it to = 1219,2X1219,2 mm

#define X_BED_SIZE 1219,2

#define Y_BED_SIZE 1219,2

in configuration.h

Yes. That will work. Or, you could always jog close to the endstops before homing.

finally we start talking the same language lets continue but wil it be 1219,2 or 1219.2 or i should just putt 1219 to each one ?

It doesn’t matter.

ok i putt 1219 i will see when it work 1 day on first setup for squaring if i have to change it

to remove the 2 X is it these line

#if ENABLED(DUAL_X_CARRIAGE)

#define X1_MIN_POS X_MIN_POS // Set to X_MIN_POS

#define X1_MAX_POS X_BED_SIZE // Set a maximum so the first X-carriage can’t hit the parked second X-carriage

#define X2_MIN_POS 80 // Set a minimum to ensure the second X-carriage can’t hit the parked first X-carriage

//#define X2_MAX_POS 353 // Set this to the distance between toolheads when both heads are homed

//#define X2_HOME_DIR 1 // Set to 1. The second X-carriage always homes to the maximum endstop position

//#define X2_HOME_POS X2_MAX_POS

i will have to // in front of all X2 like?

//#if ENABLED(DUAL_X_CARRIAGE)

#define X1_MIN_POS X_MIN_POS // Set to X_MIN_POS

#define X1_MAX_POS X_BED_SIZE // Set a maximum so the first X-carriage can’t hit the parked second X-carriage

//#define X2_MIN_POS 80 // Set a minimum to ensure the second X-carriage can’t hit the parked first X-carriage

//#define X2_MAX_POS 353 // Set this to the distance between toolheads when both heads are homed

//#define X2_HOME_DIR 1 // Set to 1. The second X-carriage always homes to the maximum endstop position

//#define X2_HOME_POS X2_MAX_POS

No. It is the line above that. It should be:

// #define DUAL_X_CARRIAGE

it is already off next

i dont see anywhere the 2 other one for the Y and Z

#define DUAL_Y_CARRIAGE

and

#define DUAL_Z_CARRIAGE

is it normal ?

DUAL_Y_CARRIAGE is just a few more lines down. A few more lines after that os the Z. But Z can handle more than 2, so the parameter changed to something like NUM_Z_DRIVERS.