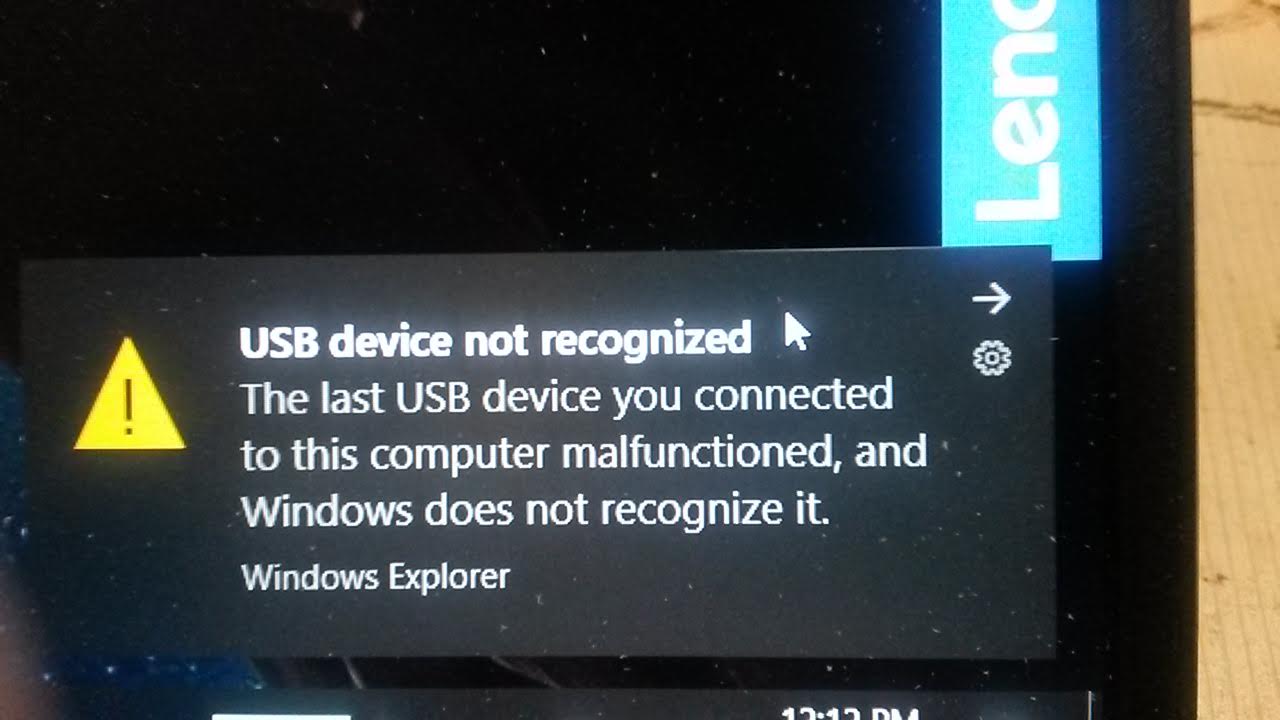

We had an accident in the shop - The MPCNC was knocked off the table and crashed to the floor. After repairing the damage, my computer will not recognize the MPCNC. There was some harness wires pulled loose and there was power on the unit .I fear that the control unit may have been fried. The message below appears on my computer. I would like to know if I can buy an updated control board from RYAN that would be compatible with the existing wire harness ? [with how to instructions ] Thanks , Joe

The boards from Ryan come flashed and will work with those wires. Since you are not using dual endstops, the minirambo is a good fit. You might also consider an LCD to do basic control without a computer and you can also run gcode from the SD card.

Hey Jeff , Thanks for the reply. I bought an LCD when I was bldg and never learned to use it. Looks complicated - are there any tutorials around ? I see Ryan is out of stock on the mini rambo. Any ideas on how long it takes to restock ? Also , I saw an article on contributing to “JEFFeb3”. How does that work ? Thanks again , Joe

There has been quite a run on the parts with the new primo kits coming, and the complicated world production issues. They were in stock not that long ago, and the contacts page shows them on order. I think the email signup in the shop is the best way to get notified when they come back.

Are you talking about contributing to me  ? I have a few options in my profile. Liberapay, or jeffeb3 on paypal or github if you have an account there.

? I have a few options in my profile. Liberapay, or jeffeb3 on paypal or github if you have an account there.

Yes I thought I’d contribute a little - You have helped me in the past & I appreciate it . Guess I’ll try Github - Thanks , Joe

Hey @jbskone, I know this is weird, but worth a shot. Have you only used USB 3 ports? Try a USB 2 or set one of the ports to 2 in the BIOS.

WEIRD, I know, but I had this problem with my Android OnePlus phone not connecting after a recent Windows update. Tried a USB 2 port and all of a sudden Windows could communicate again.

Hi Jeff, It’s been a while since we lasted talked . [ had to shut down for a while - medical problem --AOK now ]. At that time I had to replace a control board . Bought a new "Mini-Rambo. It just doesn’t work. At this point the Mini Rambo is sufficient for my needs. Should I just order another board from Ryan or is there something else that you might suggest ? Thanks , Joe

To answer your direct question, I still like the full size rambo the best.

But what do you mean it isn’t working? Is it something that was working and it broke? Or is it something we should be troubleshooting? It would be a shame to get a new one and the issue was something we could fix.

I “broke” the original board & replaced it with a new mini rambo. --. Using the same computer & the same g-codes as b-4 , I cannot get the same results. ( neither with text or images }. Will the full size rambo run with the wire harness ?

Jeff ,I miss typed - wanted to know if the full size rambo will connect using the same wire harness that I used on the mini ?

This is strange since both boards use the same microprocessor. You might want to post some examples of the issues to the forum and troubleshoot a bit before buying a new board. And yes the same wiring harness will work.

What happens is when I try to carve an image into wood using the same gcode as before , It starts cutting as before but then some of the cuts go off at crazy angles. So I started nosing around as you suggested and found an apparent anomaly – When I finish a cut , one stepper motor on the x- axis moves freely by hand , while the other 3 are still held firmly in place electronically . Seems strange ???

The free stepper is a good clue to your problem, but given your configuration, I’m not sure what to make of it. Best guess is that you either have wired your serial cable incorrectly, or your stepper is bad. In your picture of the control board, you only have 3 drivers, so I’m assuming you have your steppers wired serially. In serial wiring the current runs through coils on each motor in series. If a wire is broken, then that coil is de-powered for both motors. So either there is some sort of short or wiring problem that bypasses one of the steppers, or there is some sort of internal problem in one of the steppers that still allows current to flow. it is exceeding rare for a problem to be tracked down to a stepper motor. You could try swapping the z motor with the X motor that is not engaging to see if that solves the X movement issue. If so, then it is a stepper motor issue.

This all assumes serial wiring. If you have dual endstop wiring (a stepper driver for each stepper motor), then the stepper driver and the wiring become open game for the problem, and are more likely than a bad stepper motor.

Edit: Have you have checked the grub screw on the pulley for the motor that is moving? If the grub screw is loose, then the truck will move even though the stepper is engaged. This would account for all your symptoms, is a common problem, and is much more likely than a bad stepper motor.

GRUG SCREW IT IS !!! - Feel kinda silly, but the original problem WAS a busted circuit board . [ Which we fixed ] [ But still had a problem ]. Never considered a coincidental mechanical problem . Tunnel vision I guess . Thanks alot , Joe

As much as our robot minions want to rise up and destroy their masters (and why we need to keep an eye on them at all times), the gremlins in the grub screws are devilish and determined to drive otherwise sane men mad with consternation and impotent rage.