Swapping is fine, they can even be different types/brands. Just make sure the jumpers are correct and the firmware has the right steps.

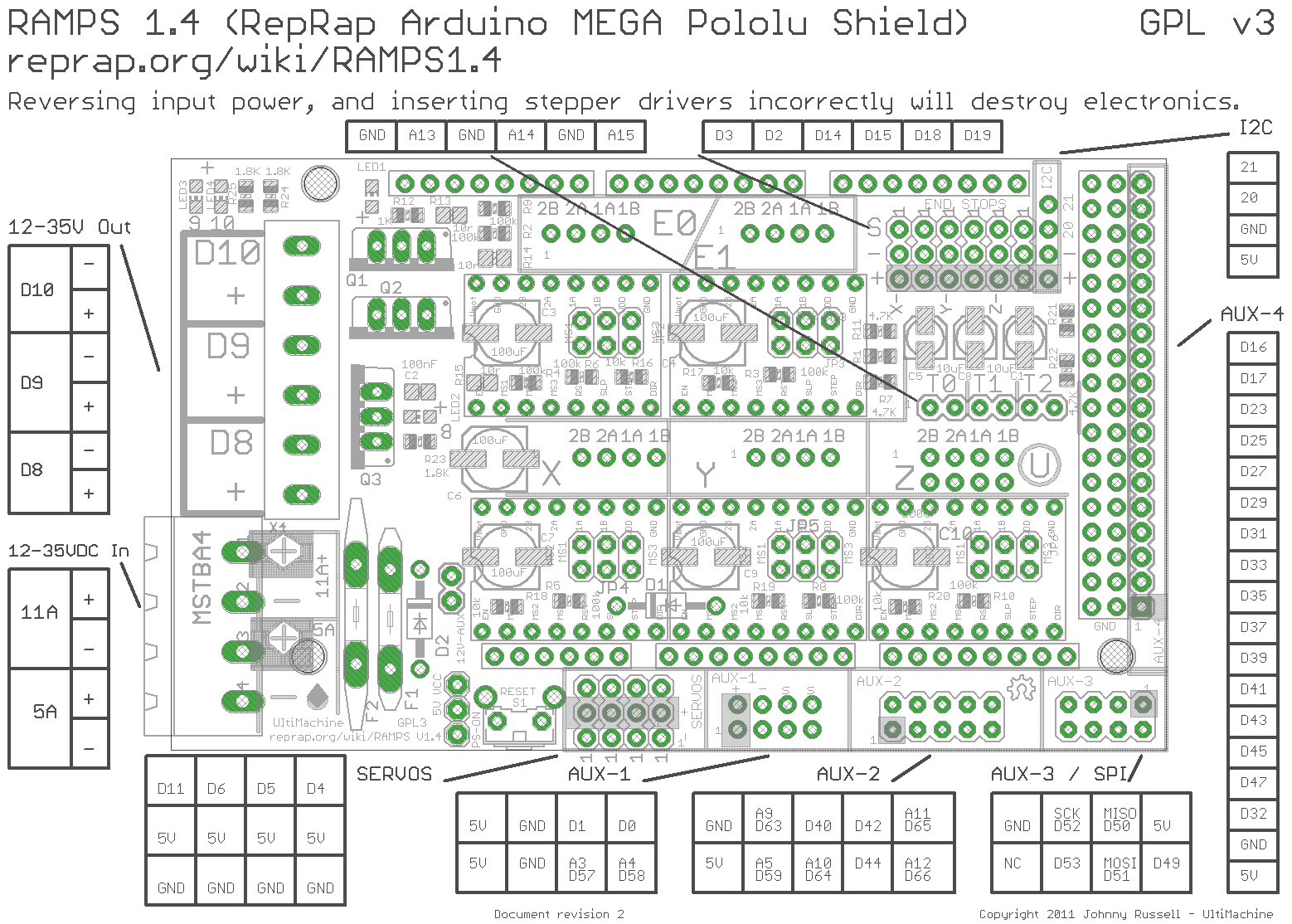

I’m about to connect the z axis to the ramps. There are 2 connections on the ramps Z axis. Do I just connect both steppers to that or do I have to splice the two steppers and connect using only one of the connectors on the ramps board? Im also looking at this (http://reprap.org/mediawiki/images/6/6d/Rampswire14.svg) connection diagram and there looks like there’s some sorta board between the steppers and the ramps that merges the two into one…do I need to do this?

Sorry still not sure which is the best approach for the z-axis on the MP3DP. When I look at the link you provided their Are 3 options.

-

order the harness. Not ideal for me…I can make my own and avoid the delay for shipping. Is the harness parallel or series?

-

Series. So this means that I do not have to change anything for amps draw on the ramps? Is this the best way to go?

-

Parralell. Do I need to increase the driver voltage in this case?

I’ve also found links on the web where the 2 Z axis are connected to the Ramps directly on the Z driver. Is this no longer valid or safe for this application?

thanks

R

The CNC needs a lot more torque. Just wire them in parallel.

W.r.t. the driver setting. If you have two motors in parallel, then the current is split between them, so to get the same limit, you would need to double it. However, I wouldn’t mess with it, because it’s probably plenty and then you would accidentally swap out with the Y and send 2x current to the Y motor.

Sorry my bad, for the printer yes, just plug them both into the board (=parallel). Sorry I was thinking LowRider…

Hi. I have a question regarding the End stop connection on ramps board I bought here. The end stops have 2 wires and the board has 3 pins. I tried googling it and I’m finding different results. Some connect to the two outer pins and some connect to the top and middle pins. Also does polarity matter?

thanks

r.

Non-powered endstops go to S and -. The polarity on the endstop does not matter but it is labeled. The firmware is programmed to use “NO” Normally open and ground or common.

I have said it in many places, endstops are not recommended.

Hi, sorry should have mentioned that this is for the MP3DP.

![]() Got him again.

Got him again.

Endstops are only recommended for printers if you plan on printing with them.

Dang it… Sorry, yup use those endstops. I guess I need to pay more attention to my own forum categories.

No problem. So back to the original question regarding the pins on the Ramps board. Which ones do I use? There are three pins colored red, black & blue and the polarity is not labeled.

[attachment file=“rampsEndStops.gif”]

No problem. So back to the original question regarding the pins on the Ramps board. Which ones do I use? There are three pins colored red, black & blue and the polarity is not labeled.

Hi…has anyone come up with an way of mounting the heated bed so that the bolt heads are not on the surface of the bed? My ANYCUBIC Mega I3 has a flush surface, and I’m assume that the leveling bolts screw into the bed itself (i.e. the holes in the bed are threaded) or they welded the leveling bolts to the heat bed. I can’t tell because the surface is covered with their priority printing surface.

Usually the glass is thicker than the screw heads, or if you use an aluminum bed you can use countersunk screws and make them flush.

Mine looks like this: (but it depends which bed you have)

[attachment file=38289]