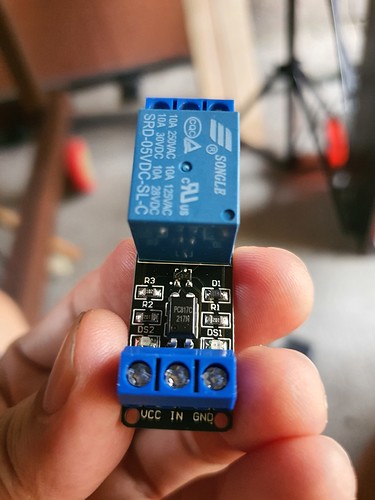

Hi! Can i use this relay to power my router?

Which router are you using?

The makings in the case show that it can handle up to 10 amps, so it should be ok.

But depending on which router you are using, it may be a good idea to use that relay to activate a larger relay to power the router.

People on this forum have used similar relays to control their router, and you probably could make it work, but there are two problems with this relay:

It is a 5V relay. The typical solution for turning a router on and off is to use a fan pin and turn it on using a M106/M107 gcode. Unfortunately fan pins are almost always 12V or more. In theory you could select an arbitrary free pin and use an M42 to toggle it, but is a less traveled road.

It has been suggested by people on this forum who know far more about electronics/electricity than I do that a router may have a high startup current and 10A is just not enough. This result is a short life for the relay. They recommend that if a person was to use this style of solution, to purchase something more like this. Or perhaps a short life is not an issue since in this use there are relatively few activations.

It may be more money than you want to spend, but I use one of these to control my router.

Just a 300w palm router

My rambo v1.4 fan seems a 5v type because i bought a 40mmx40mm 12v fan and its connector is a little bigger than the fan port of the rambo board.

You mean i better get a higher ampere relay or this 10amps is enough for a 300w motor palm router?

Unfortunately, that iot switch is not available here in philippines. I even search aliexpress for that but to no avail. Though amazon will ship here but it will be costly and will take longer time

I would put a multimeter on your fan pin. I would be very surprised if it is 5V. I have a Rambo board, and it is definitely 12V. But an alternative solution to going the M42 route to get a 5V pin would be to reassign the fan to a known 5V pin in the pins_ file. This will require compiling Marlin and reflashing the board.

According to some forum posts, MPCNC users have use similar 10A to switch their router on and off. I just don’t know if the relay will last.

That relay is more than enough to run the palm router.

Like @robertbu said, the biggest issue is the voltage that your board is putting out to activate the relay. That will take some more investigation on your part.

Because it is a relay, and not a variable speed control, you can use a digital (on/off) pin. You don’t need a PWM pin like the fans. I don’t know the Rambo well enough to point to a specific pin, but you’ll only need to define the SPINDLE ENABLE feature, assuming you don’t have a reversible variable speed spindle.

Instructions for configuring Marlin spindle/laser settings

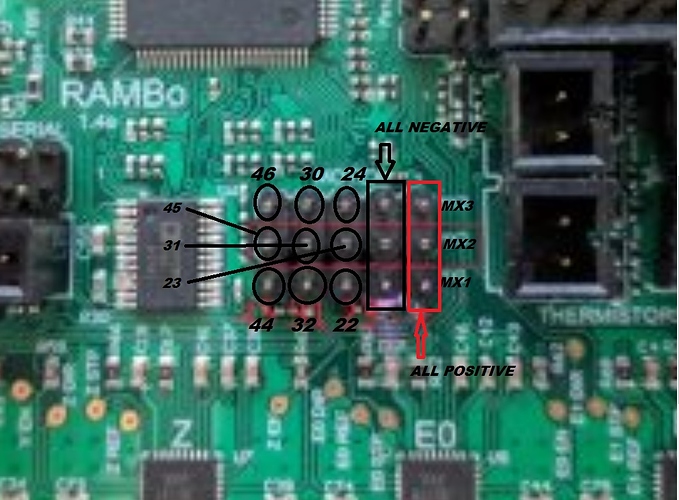

Here is a block of pins you can use:

Note that the firmware maintained by V1 has the laser enabled and uses pins 31, 32, and 45, so you may want to avoid these pins:

// // M3/M4/M5 - Spindle/Laser Control // #define SPINDLE_LASER_PWM_PIN 45 // Hardware PWM #define SPINDLE_LASER_ENA_PIN 31 // Pullup! #define SPINDLE_DIR_PIN 32

Pins 44, 45, and 46 are PWM. The other are not.

There is an easy way to make the fan pin 5V. Test this with a Volt Meter first but this is what I did for a laser that needed 5V TTL.

Connect the negative Fan pin to the Negative on the relay.

Connect the Positive relay pin to a Random +5V pin on the Rambo. I used one from a Endstop.

See the Rambo board fan pins are like this. the + pin is always +12V. It never changes. But the Negative pin switches from Ground to open. So all you need is to use a different +5 pin and you are golden.

Cheers!

Yes something like this i want, just an on/off signal port

It’s pretty common to “share” pins between spindle and laser and then choose a “mode.” Here’s my understanding of the general differences between the modes.

Spindle mode:

- Use PWM pin to control spindle RPM (only use if your spindle supports this)

- Use ENA(ble) pin to turn spindle on/off (this is where you’d connect your relay)

- Use DIR pin to reverse spindle rotation (only use if your spindle supports this)

- Spindle moves to “Safe Z” height but stays enabled during non-cutting moves

- Has a short delay when turned on or RPM changed to allow physical spindle to align to commanded speed

Laser Mode:

- Use PWM to control laser intensity/power level

- May use ENA(ble) pin to turn laser on/off, or interpret 0% intensity as “turn off” command - depends on the laser

*DIR pin gets ignored - no reversing the light flow

*Laser is disabled during non-cutting moves, but Z height doesn’t need to be changed

*No motion pauses for intensity changes

If you’re using a laser in spindle mode you end up with burned corners as the intensity stays high as the machine slows down to make the turn.