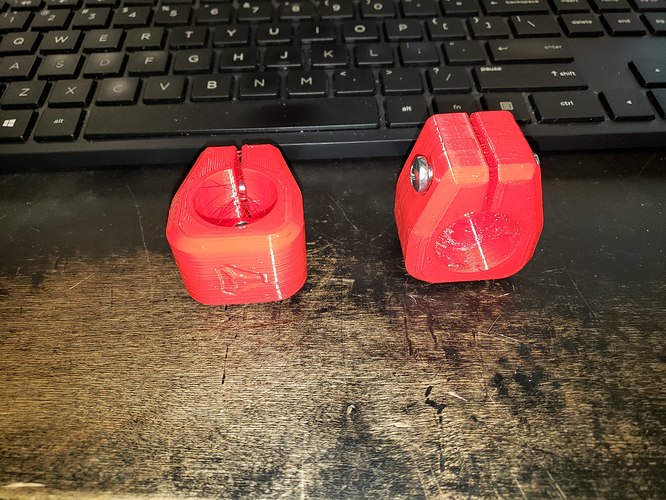

Starting my log off with screen prints from my slicer. My first two parts printed without issues. I’m happy with them. I’m sure they could be better, but they fit the EMT conduit and look pretty good.

Please feel free to murder my settings. I’m always happy to learn something new. Let me know if I’m overdoing the information.

Printer: Anycubic I3 Mega S

Slicer: Prusa

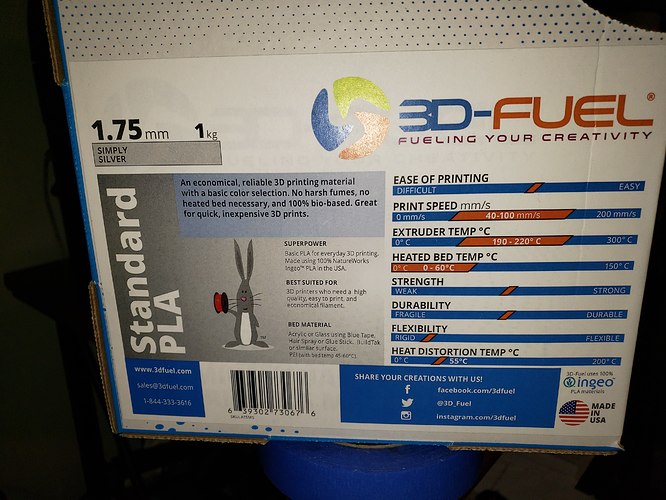

Filament: 3D Fuel (Fire-engine Red, Simply Silver)

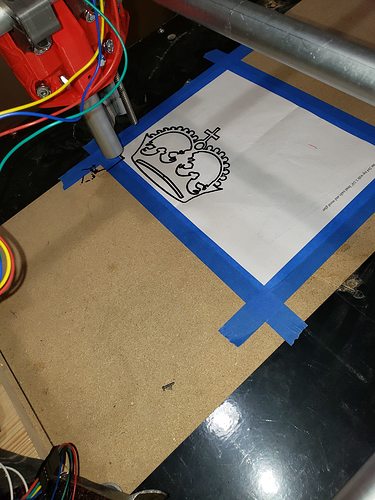

Router: Bosch Colt

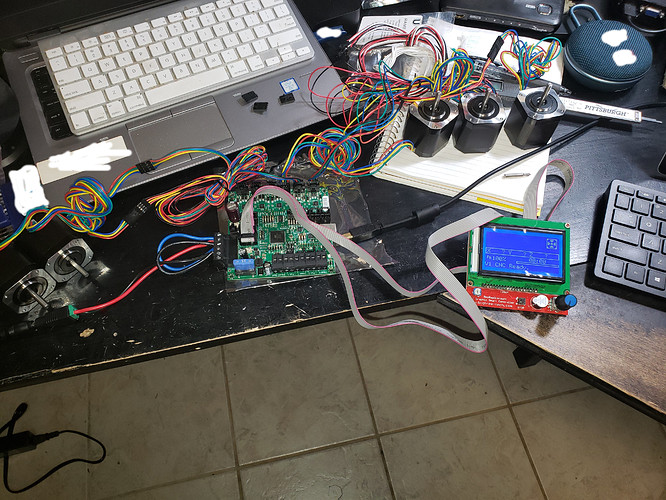

Controller: Rambo 1.4

Work Area: 24x36

EMT: 3/4 23.5mm (Lowes)

Here goes:

Prusu_Config_Export:

# generated by PrusaSlicer 2.2.0+linux-x64 on 2021-02-27 at 21:27:59 UTC

[print:PLA MPCNC Core]

avoid_crossing_perimeters = 0

bottom_fill_pattern = rectilinear

bottom_solid_layers = 4

bottom_solid_min_thickness = 0

bridge_acceleration = 0

bridge_angle = 0

bridge_flow_ratio = 1

bridge_speed = 60

brim_width = 0

clip_multipart_objects = 1

compatible_printers =

compatible_printers_condition =

complete_objects = 0

default_acceleration = 0

dont_support_bridges = 0

draft_shield = 0

elefant_foot_compensation = 0.2

ensure_vertical_shell_thickness = 1

external_perimeter_extrusion_width = 0.45

external_perimeter_speed = 50%

external_perimeters_first = 0

extra_perimeters = 1

extruder_clearance_height = 20

extruder_clearance_radius = 20

extrusion_width = 0.45

fill_angle = 45

fill_density = 70%

fill_pattern = rectilinear

first_layer_acceleration = 0

first_layer_extrusion_width = 0.42

first_layer_height = 0.35

first_layer_speed = 15

gap_fill_speed = 20

gcode_comments = 1

gcode_label_objects = 1

infill_acceleration = 0

infill_every_layers = 1

infill_extruder = 1

infill_extrusion_width = 0.45

infill_first = 0

infill_only_where_needed = 0

infill_overlap = 25%

infill_speed = 70

inherits =

interface_shells = 0

layer_height = 0.2

max_print_speed = 80

max_volumetric_speed = 0

min_skirt_length = 0

notes =

only_retract_when_crossing_perimeters = 1

ooze_prevention = 0

output_filename_format = [input_filename_base].gcode

overhangs = 1

perimeter_acceleration = 0

perimeter_extruder = 1

perimeter_extrusion_width = 0.45

perimeter_speed = 60

perimeters = 4

post_process =

print_settings_id =

raft_layers = 0

resolution = 0

seam_position = random

single_extruder_multi_material_priming = 1

skirt_distance = 6

skirt_height = 1

skirts = 0

slice_closing_radius = 0.049

small_perimeter_speed = 15

solid_infill_below_area = 70

solid_infill_every_layers = 0

solid_infill_extruder = 1

solid_infill_extrusion_width = 0.45

solid_infill_speed = 30

spiral_vase = 0

standby_temperature_delta = -5

support_material = 0

support_material_angle = 0

support_material_auto = 1

support_material_buildplate_only = 0

support_material_contact_distance = 0.25

support_material_enforce_layers = 0

support_material_extruder = 1

support_material_extrusion_width = 0.35

support_material_interface_contact_loops = 0

support_material_interface_extruder = 1

support_material_interface_layers = 4

support_material_interface_spacing = 0.4

support_material_interface_speed = 100%

support_material_pattern = rectilinear-grid

support_material_spacing = 1

support_material_speed = 60

support_material_synchronize_layers = 0

support_material_threshold = 60

support_material_with_sheath = 1

support_material_xy_spacing = 0.4

thin_walls = 1

threads = 4

top_fill_pattern = rectilinear

top_infill_extrusion_width = 0.4

top_solid_infill_speed = 20

top_solid_layers = 4

top_solid_min_thickness = 0

travel_speed = 130

wipe_tower = 0

wipe_tower_bridging = 10

wipe_tower_no_sparse_layers = 0

wipe_tower_rotation_angle = 0

wipe_tower_width = 60

wipe_tower_x = 180

wipe_tower_y = 140

xy_size_compensation = 0

[print:PLA MPCNC parts]

avoid_crossing_perimeters = 1

bottom_fill_pattern = rectilinear

bottom_solid_layers = 4

bottom_solid_min_thickness = 0

bridge_acceleration = 0

bridge_angle = 0

bridge_flow_ratio = 1

bridge_speed = 40

brim_width = 0

clip_multipart_objects = 1

compatible_printers =

compatible_printers_condition =

complete_objects = 0

default_acceleration = 0

dont_support_bridges = 0

draft_shield = 0

elefant_foot_compensation = 0.2

ensure_vertical_shell_thickness = 1

external_perimeter_extrusion_width = 0.45

external_perimeter_speed = 50%

external_perimeters_first = 0

extra_perimeters = 1

extruder_clearance_height = 20

extruder_clearance_radius = 20

extrusion_width = 0.45

fill_angle = 45

fill_density = 45%

fill_pattern = rectilinear

first_layer_acceleration = 0

first_layer_extrusion_width = 0.42

first_layer_height = 0.35

first_layer_speed = 15

gap_fill_speed = 20

gcode_comments = 1

gcode_label_objects = 1

infill_acceleration = 0

infill_every_layers = 1

infill_extruder = 1

infill_extrusion_width = 0.45

infill_first = 0

infill_only_where_needed = 0

infill_overlap = 25%

infill_speed = 50

inherits =

interface_shells = 0

layer_height = 0.3

max_print_speed = 50

max_volumetric_speed = 0

min_skirt_length = 0

notes =

only_retract_when_crossing_perimeters = 1

ooze_prevention = 0

output_filename_format = [input_filename_base].gcode

overhangs = 1

perimeter_acceleration = 0

perimeter_extruder = 1

perimeter_extrusion_width = 0.45

perimeter_speed = 50

perimeters = 4

post_process =

print_settings_id =

raft_layers = 0

resolution = 0

seam_position = random

single_extruder_multi_material_priming = 1

skirt_distance = 6

skirt_height = 1

skirts = 0

slice_closing_radius = 0.049

small_perimeter_speed = 15

solid_infill_below_area = 70

solid_infill_every_layers = 0

solid_infill_extruder = 1

solid_infill_extrusion_width = 0.45

solid_infill_speed = 30

spiral_vase = 0

standby_temperature_delta = -5

support_material = 0

support_material_angle = 0

support_material_auto = 1

support_material_buildplate_only = 0

support_material_contact_distance = 0.25

support_material_enforce_layers = 0

support_material_extruder = 1

support_material_extrusion_width = 0.35

support_material_interface_contact_loops = 0

support_material_interface_extruder = 1

support_material_interface_layers = 4

support_material_interface_spacing = 0.4

support_material_interface_speed = 100%

support_material_pattern = rectilinear-grid

support_material_spacing = 1

support_material_speed = 60

support_material_synchronize_layers = 0

support_material_threshold = 60

support_material_with_sheath = 1

support_material_xy_spacing = 0.4

thin_walls = 1

threads = 4

top_fill_pattern = rectilinear

top_infill_extrusion_width = 0.4

top_solid_infill_speed = 20

top_solid_layers = 4

top_solid_min_thickness = 0

travel_speed = 130

wipe_tower = 0

wipe_tower_bridging = 10

wipe_tower_no_sparse_layers = 0

wipe_tower_rotation_angle = 0

wipe_tower_width = 60

wipe_tower_x = 180

wipe_tower_y = 140

xy_size_compensation = 0

[filament:PLA for MPCNC]

bed_temperature = 60

bridge_fan_speed = 100

compatible_printers =

compatible_printers_condition =

compatible_prints =

compatible_prints_condition =

cooling = 1

disable_fan_first_layers = 3

end_filament_gcode = “; Filament-specific end gcode \n;END gcode for filament\n”

extrusion_multiplier = 1

fan_always_on = 0

fan_below_layer_time = 60

filament_colour = #000000

filament_cooling_final_speed = 3.4

filament_cooling_initial_speed = 2.2

filament_cooling_moves = 4

filament_cost = 24

filament_density = 0

filament_deretract_speed = nil

filament_diameter = 1.72

filament_load_time = 0

filament_loading_speed = 28

filament_loading_speed_start = 3

filament_max_volumetric_speed = 0

filament_minimal_purge_on_wipe_tower = 15

filament_notes = “”

filament_ramming_parameters = “120 100 6.6 6.8 7.2 7.6 7.9 8.2 8.7 9.4 9.9 10.0| 0.05 6.6 0.45 6.8 0.95 7.8 1.45 8.3 1.95 9.7 2.45 10 2.95 7.6 3.45 7.6 3.95 7.6 4.45 7.6 4.95 7.6”

filament_retract_before_travel = nil

filament_retract_before_wipe = 1%

filament_retract_layer_change = 1

filament_retract_length = 2

filament_retract_lift = nil

filament_retract_lift_above = nil

filament_retract_lift_below = nil

filament_retract_restart_extra = nil

filament_retract_speed = 70

filament_settings_id = “”

filament_soluble = 0

filament_toolchange_delay = 0

filament_type = PLA

filament_unload_time = 0

filament_unloading_speed = 90

filament_unloading_speed_start = 100

filament_vendor = (Unknown)

filament_wipe = nil

first_layer_bed_temperature = 60

first_layer_temperature = 200

inherits =

max_fan_speed = 100

min_fan_speed = 35

min_print_speed = 10

slowdown_below_layer_time = 5

start_filament_gcode = “; Filament gcode\n”

temperature = 200

[printer:anycubic]

bed_custom_model =

bed_custom_texture =

bed_shape = 0x0,210x0,210x210,0x210

before_layer_gcode =

between_objects_gcode =

cooling_tube_length = 5

cooling_tube_retraction = 91.5

default_filament_profile = “”

default_print_profile =

deretract_speed = 0

end_gcode = M104 S0 ; turn off temperature\nM84 ; disable motors\nM204 S4000\nM205 X20 Y20\nM107\nM104 S0 ; turn off extruder\nM140 S0 ; turn off bed\nM84 ; disable motors\nM107\nG91 ;relative positioning\nG1 E-1 F300 ;retract the filament a bit before lifting the nozzle, to release some of the pressure\nG1 Z+0.5 E-5 ;X-20 Y-20 F100 ;move Z up a bit and retract filament even more\nG28 X0 ;Y0 ;move X/Y to min endstops, so the head is out of the way\nG1 Y180 F2000\nG90\nM300 P300 S4000\nM82 ;absolute extrusion mode\nM104 S0

extra_loading_move = -2

extruder_colour = “”

extruder_offset = 0x0

gcode_flavor = marlin

high_current_on_filament_swap = 0

host_type = octoprint

inherits =

layer_gcode =

machine_max_acceleration_e = 10000,5000

machine_max_acceleration_extruding = 1500,1250

machine_max_acceleration_retracting = 1500,1250

machine_max_acceleration_x = 9000,1000

machine_max_acceleration_y = 9000,1000

machine_max_acceleration_z = 500,200

machine_max_feedrate_e = 120,120

machine_max_feedrate_x = 500,200

machine_max_feedrate_y = 500,200

machine_max_feedrate_z = 12,12

machine_max_jerk_e = 2.5,2.5

machine_max_jerk_x = 10,10

machine_max_jerk_y = 10,10

machine_max_jerk_z = 0.2,0.4

machine_min_extruding_rate = 0,0

machine_min_travel_rate = 0,0

max_layer_height = 0

max_print_height = 200

min_layer_height = 0.07

nozzle_diameter = 0.4

parking_pos_retraction = 92

print_host = http://192.168.10.4:5000

printer_model =

printer_notes =

printer_settings_id =

printer_technology = FFF

printer_variant =

printer_vendor =

printhost_apikey = xxxxx

printhost_cafile =

remaining_times = 1

retract_before_travel = 1

retract_before_wipe = 0%

retract_layer_change = 1

retract_length = 3.2

retract_length_toolchange = 10

retract_lift = 0.6

retract_lift_above = 0

retract_lift_below = 209

retract_restart_extra = 0

retract_restart_extra_toolchange = 0

retract_speed = 40

serial_port =

serial_speed = 250000

silent_mode = 0

single_extruder_multi_material = 0

start_gcode = G28 ; home all axes\nG1 Z5 F5000 ; lift nozzle\n

thumbnails =

toolchange_gcode =

use_firmware_retraction = 0

use_relative_e_distances = 0

use_volumetric_e = 0

variable_layer_height = 1

wipe = 1

z_offset = 0.15

[presets]

print = PLA MPCNC parts

sla_print =

sla_material =

printer = anycubic

filament = PLA for MPCNC

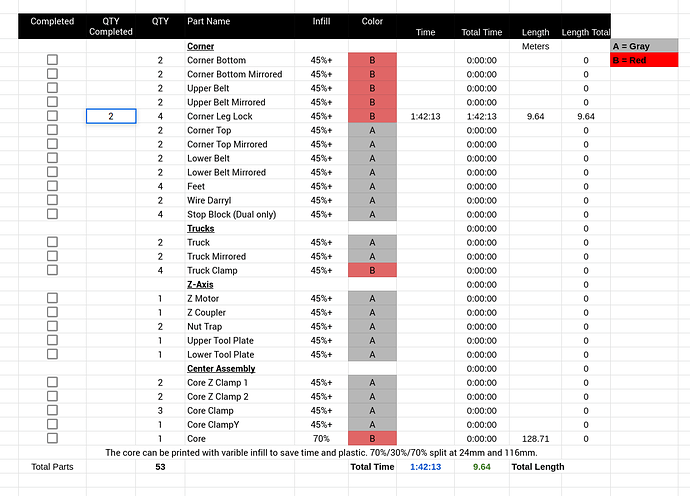

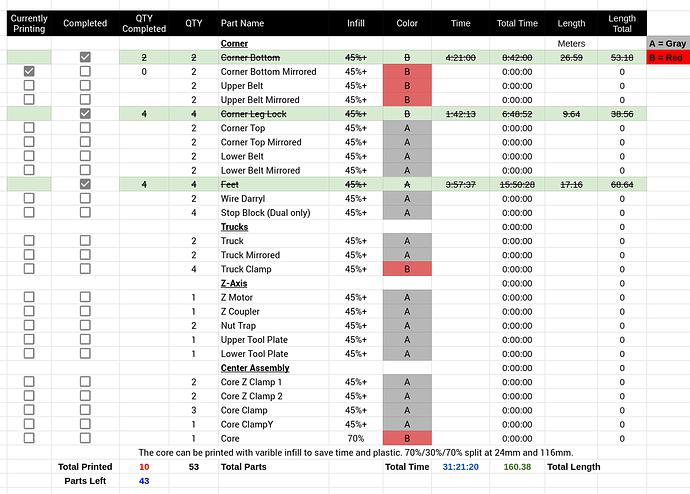

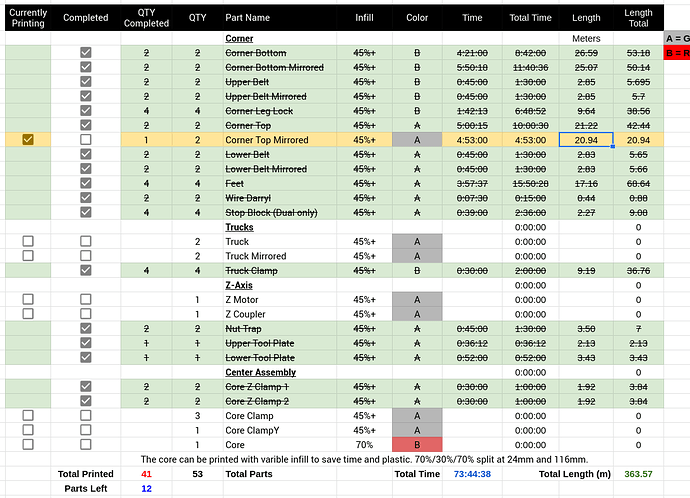

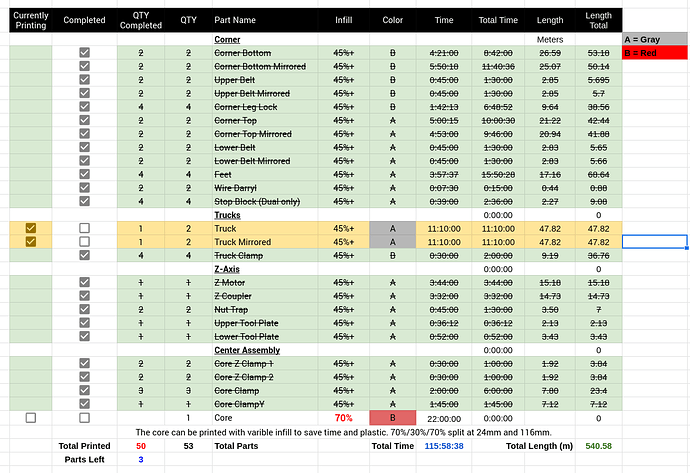

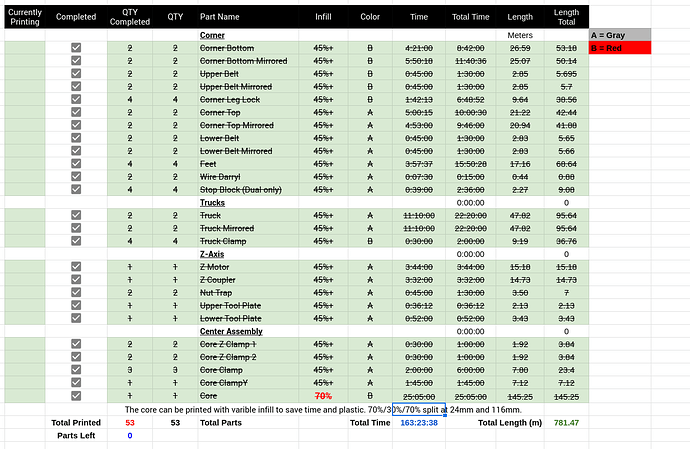

Keeping track of things:

Printer and Filament:

Printed Parts (I’ll keep adding some here as I go).

Electronics Tested good: