Another addition to why we watch our machines…

Last night, cutting small job had vacuum disconnected (shop vac was in the basement and I didn’t feel like going to get)

Mistake #1

Had loose end of vacuum nose dangling over edge of / near MPCNC (

Mistake #2

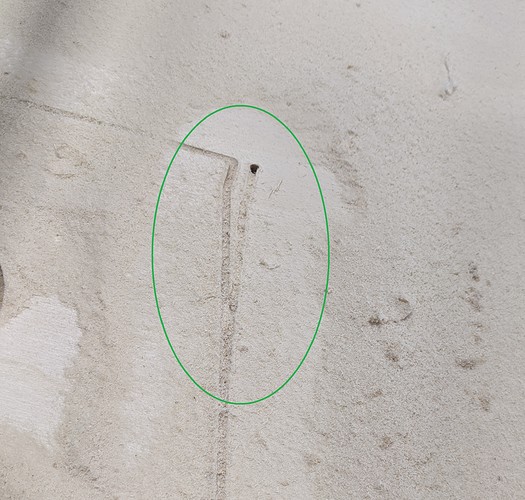

I was two feet away from the above photo, reading an email on my phone and thinking only two more passes around and this cut is done! And then I detected a change in tone from the router, it didn’t hit me at first but the stepper clicking sure did.

MPCNC had deviated from cutting path and was cutting a a fresh route at .405" depth.

On one hand I was proud of the little sucker plowing thru and valiantly trying to complete the task at hand.

On the other, what the heck is going on here?

Loose grub screw? Nope

Broken belt? Nope

Controller / Wiring glitch? Nope

That loose dangling hose had gotten trapped, compressed and wedged between the perimeter tubing and the x-axis, hindering any change in direction along that axis. But the y-axis was unhindered so the MPCNC, like a good soldier, carried on to the best of it’s ability.

Now since I was right there, I was able to abort and put the dewalt out of it’s screaming misery and access the damages. (It’s funny to me that at times I think the MPCNC cuts slow, but it sure cut an inch long path pretty quick here!)

Ok some deviation on the cut, but good news it veered outside the path of the cut, not inside, so as long I could re-zero I might be able to salvage the piece (I could, and I did - not perfect but close enough that a little sanding took care of it).

One bit who’s tip was blackened, but surprisingly completed the cut in the 1/2" baltic birch stock. (Have not tried any new cuts with the bit to see if it truly is still usable).

One big slap on the forehead for not moving the hose completely out of the way or not hooking up the vacuum before beginning (I attribute that to being excited about getting started cutting early on a Friday night while the wife was out of the house)

One very big sigh of relief on how LUCKY I was that:

A) I was right near the machine where I should be

B) I was cutting baltic birch and not MDF

C) There was NO burning of the plywood at all (Due to one of Ryan’s fantastic bits? maybe…)

D) I was able to shut down quickly and avoid any serious damages to project, machine or house.

What could have happened had I NOT been right there? (Those thoughts took over after I re-zeroed and completed the cut. As a result, I shut the MPCNC down after the cut, counted my lucky stars and called it a night).

Now is there any long term damage to the MPCNC?

Dunno, streched belt? maybe…

$5 bit burned to toast? maybe…

Shortened life on gears, steppers etc due to trying to cut damn near 1/2" deep in one pass? I’ll know sometime or I won’t.

Bottom line to this little tale of not so much woe?

Stay near your machine when cutting because you NEVER know what could happen.

(Link chosen at random as an example - not an endorsement of this vendor.)

(Link chosen at random as an example - not an endorsement of this vendor.)

(Or source it from someone here…)

(Or source it from someone here…)