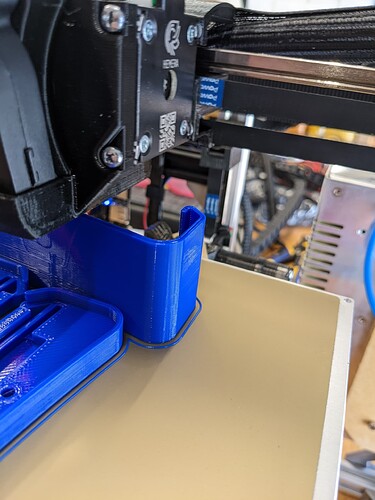

I’m guessing here that I’m looking at a Z motor on its side?

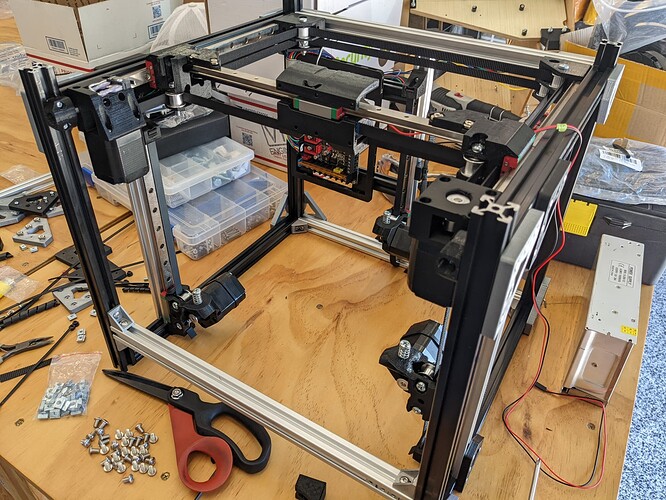

Now I’m kinda torn. I have all the pieces and printed parts for a Repeat printer sitting here, finally got my heated bed in Thursday for a regular sized 220mm square build…

Well hopefully I will have this up and running in a couple days so maybe wait and see how the rail goes vs the CF tube.

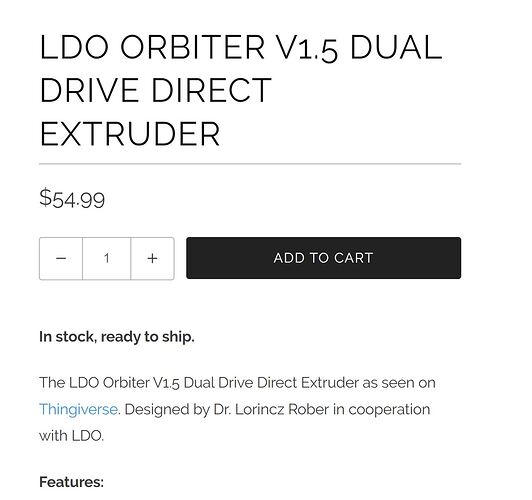

Ryan any progress? I would like to see how you build using the extrusion. If your still looking for an lite extruder look at the orbiter.

Lemme get a snap. I think I will have it printing today unless I take a half day jet ski getaway…

I am set up for the hemera’s I have but the orbiter is on the short list if I swap.

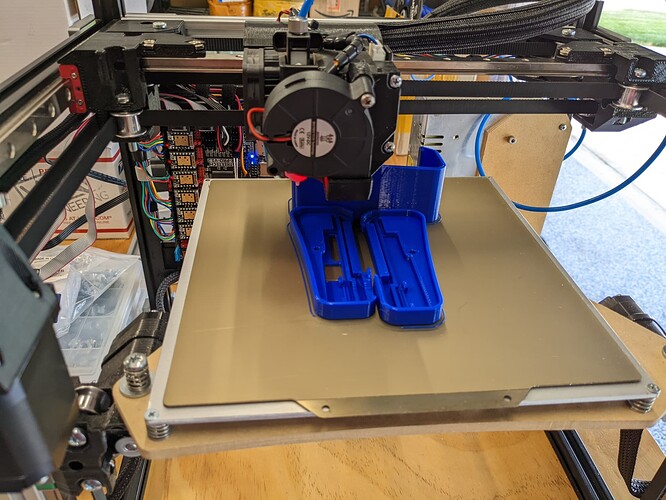

All the parts are pretty rough but it makes it more likely to rework them. So if it works well I’ll make them look a bit fancier. There is room to add a CF tube if needed, but I don’t think it is.

So are you going to look at refreshing the v2 anytime? I really do not want the expense of a core xy printer, but sometimes I just see that v2 and want one.

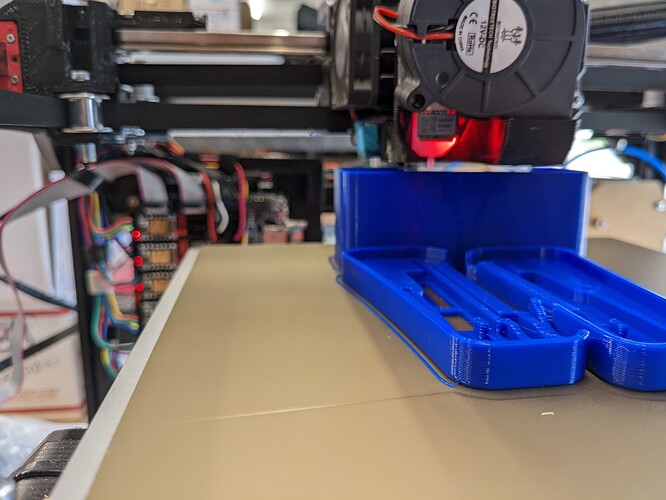

No, I don’t think so. The CoreXY far outperforms the V2 bed slinger. It is a pretty huge step backwards. The speed, print quality, and ease of use are just much better. To the point I feel weird not use some sort of high flow extruder. I am easily constrained by max flow and to a lesser degree part cooling.

Thanks Ryan. It looks awesome can’t wait to for new parts. Did did you end up making a 300 x 300?

Not yet. I did the CAD in 300 and made sure it works with 200. I have 5 printers with 200mm parts left to convert. The ones with PCB beds I will probably swap out to 300’s

Glad you left provisions for the cf tube! I ended up asking for a refund on those stupid linear rails i was waiting for so now I get to find more to order. Got half a sheet of half inch prefinished ply laying around. Orbiter 2.0…so light!

I really gotta catch up the honey do list, so I can get some fun stuff done!

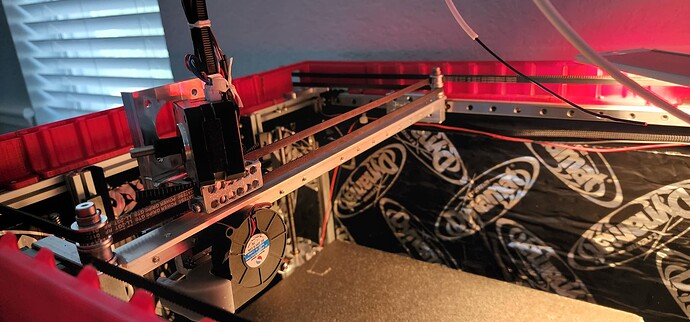

These are the new X/Y steppers I put on my printer. Soooo much torque!

Also, I don’t think I’ve seen a printer that has the Z motors ride with the build plate yet.

It saves so much space! This one has a much smaller footprint volume than the last one with actually a bit more build volume. Can’t wait to show a side by side picture.

The extruder to rail mount is night and day better than the wheels and CF tube mount. Much more rigid. And if you where to do a bowden or ultra light setup it has lots of room to do stuff on the side instead of just out front.

I think I am starting to see signs of my CF tubes cracking on the Repeat, I am getting odd printing artifacts.

I have a nice wire routing loop that seems awesome.

I have yet to work out a great filament loop, but I do think I have an idea for that.

Printed extrusion brackets are no good. Any of the metal ones are good. I think I want to swap some out for wood or plastic milled ones to add some flair.

So far this can be build in a box and does not have to be extrusion based, but I really want to mount that “B” stepper on top of the rail to solve my one issue. If I did that an alternate version would be super easy to make for a “in a box” version.

Just throwing this out there, probably alright on your smaller build, but the rail might need a backer for a 300mm printer. My printer’s rail is rotated 90deg from yours and it gets “floppy” at high speeds. A few of us are using aluminum angle as a backer/stiffener.

I did leave that possibility open. The center extruder mount can be made taller, easily in my CAD and mounting to the ends just requires longer screws.

I did see that printer and wonder why they would mount the rail in that orientation. I chose the weak direction to only have to support the extruder weight, not the insane accelerations. The other thing about that one that strikes me a bit odd is those idlers screws not being supported. Has anyone looked to see if they flex under high loads? The tiniest of supports will easily make those screws 4x more rigid, and there is plenty of room to add a strap from the tops on all of them. Other than that, that printer is seeeeexy!

The shoulder bolts are pretty beefy. A few of the guys did do double shear mounts for them. Ends up being a bar across the Y (same as the stiffener) axis. You couldn’t do it like this with printed parts, but the milled aluminum parts help. Back when Steve and Craig designed this printer 100mm/s was travel speeds. Now a couple of the guys are printing at 1m/s!

Yeah those accelerations multiply the loads seen, at least it is linear. F=ma. It really really makes you take a second look at it all. A lot of those super speed print videos are starting to look a lot like paint shakers.