Hi guys,

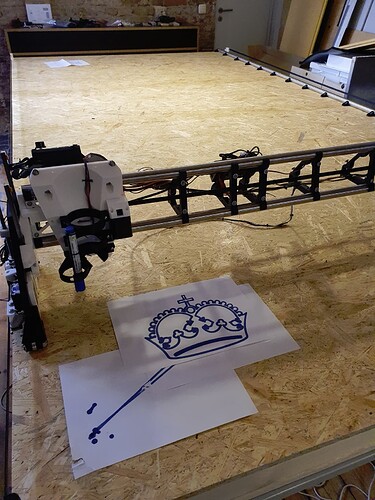

I have my build set up so far, large 3050mm x 1505mm cut size + table. Came to some little things like snapping Y belt endstops, maybe the lenght is a problem, just printing some new parts with 100% infill of the base. Maybe these need to be improved somehow or I have to build some metal holder.

Anyways, I have some troubles getting the machine up and running.

Everything is assembled, I’m using the proposed SKR Pro 1.2 with Touch TFT in its specific cases. I dont yet understand how to connect the closed cases with my PC, I guess its through the USB slot of the TFT? This was not very deeply covered in the setup instructions, nor the use of the TFT. What does it mean that “TFT is in listening mode”? As I cant control any movement with the TFT at all.

Connection issue:

I have some connection trouble with Repetier, therefor tried to set the baud rate in the TFT settings menu, with no luck.

I ordered a new 10m USB A to USB B cable as my old one might be too old, I’m given a 115000 baud error in Repetier Host. I could connect once but the machine wouldnt move, now I cant connect at all anymore. I guess I will wait for that cable which should arrive today to see if that works.

Z-Homing:

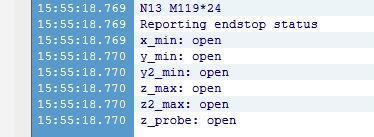

X and Y homing does work properly, Z does not. I found the proper pins (I guess), namely X2 and the empty PIN. Z is shown as +200 in the lowest position, I have to lower the value to +120 max (top position) which looks strange to me (but default settings in the LR dual firmware). If I reverse the motors its wrong, obviously. If I start HOME Z it now moves up but does not stop when hitting the Z endstops.

→ sounds kind of correct to me as its not going up in numbers but down and therefor might not expect any endstops??

Z-Probe:

I tried setting up the Z-probe by adding a touchplate (those round ones, maybe 15mm high) to the touch pin. I raised the Z axis (lowered the value to sth like 140) and started HOME Z. The axis went down and I closed the Z-probe by touching the plate with the clamp - no result, no stop.

Any ideas what I’m doing wrong?

As I dont have a proper PC connection I tried to use the SKR / TFT terminal with some G code snippets but with no luck  Guess its not working this way

Guess its not working this way

Looking forward to your help

Niko

The only opening is in the TFT case, for TF card or USB A…

The only opening is in the TFT case, for TF card or USB A…