Thanks Ryan! (@vicious1). I wasn’t aware you started to flash them, and I keep lurking here, so it is good to know.

So i should either buy the wiring set offered on V1 or get longer 4-6 pin stepper cables? Also only tried the LCD once and it would flash and then beep very loudly, never showed any sort of menu.

I know the wiring kit from Ryan works great. But you should be able to get the same results with another cable.

Maybe the gray cables are wired backwards? That can lead to beeping and a blank screen in marlin mode.

So it would be X and E0 for X, Y and E1 for Y, for instance? Thanks for all the tips and ill try swappi g the cables for LCD but Im pretty sure they were right…

Yep.

Again, thanks for all the help. I got everything wired with the v1 wiring set up that worked with my last board and now it seems motors are moving independently or something…? Both axes just grind and dont move anywhere. I flip the the black molex(?) comnectors and still the same issue. Machine moves more or less ok when powered and moved by hand. This was a working machine the onyl thing Ive changed is board and now spindle.

It sounds like maybe the motors are wired wrong still? Don’t trust the colors. Each stepper has two coils and each coil has two wires. The most important thing is that you get the two coils separated so if you have an A coil and a B coil, they are wired AABB.

One easy way to tell if two wires are part of the same coil is to unplug them from everything and connect two wires. If the motor is much harder to turn (by hand) then those two wires are part of one coil. The other two are part of the other coil.

I do think its wiring as well. Mind simplifying what you mean by disconnecting and then only connecting 2 out of the presumably 4 wires? Total layman with electrical but trying to get better. Also, have 4 pin connectors so I cant flip them on the controal board side. Each axis has 2 6 pin connectors and a molex to splice them together, for what its worth…

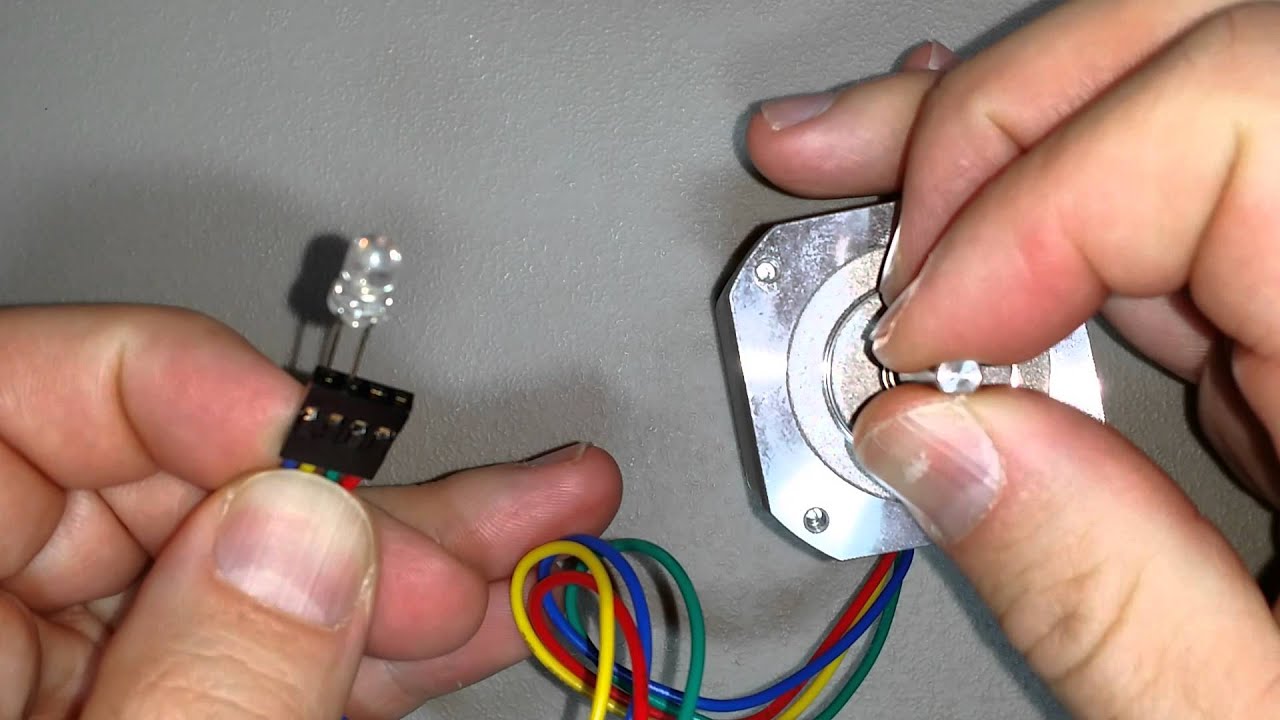

It is kind of like this, I couldn’t find a better video of it:

Except, instead of using an LED, you can use any wire to short or connect the blue and yellow.

If you got two wires in the same coil, instead of an led lighting up, the motor will get harder to turn.

If you didn’t get two wires on the same coil, then it will still be easy to turn.

You want them wired just like this, with two wires from one coil on one side and the other two wires from the second coil on the other side.

I will try that. Just unsure of how it couldnhave gone wrong from the last board if I didnt change anything…hmm. i dont suppose the difference in 6 pin connectors to motors matters? Ie. Swap them out per axis?