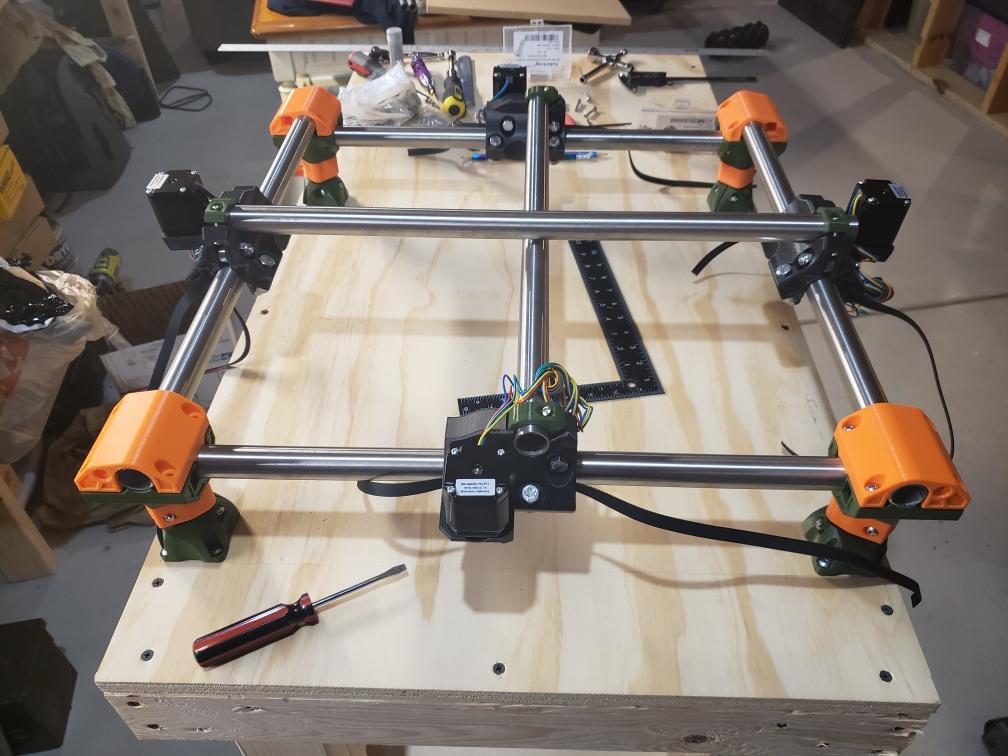

Oh yeah!!! Ready to build!! Still have to cut the legs. That’s the last thing I gotta do oh and finish the table lolz. Another trip to depot for me today.

Made some head way on my build tonight!

I got the legs installed and about as perfectly squared as you can get.

I used some CA glue to keep the nuts.

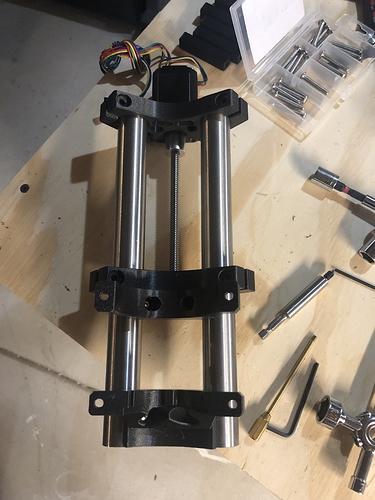

Beginning of the trucks.

Installed the idlers and belts.

It’s coming along! Got the rails and trucks installed and called it a night.

Got my new z axis rails today so I’ll be working on that tonight.

So I’m on the squaring step. Y axis is within 1 mm. X axis is around 5. So I’ve been tightening and playing with tensioning the clamps to adjust this, however, I notice I have play in the gantry. See video:

Is this normal? Is there something else I’m suppose to tighten?

That seems like a lot of play!? Are you sure all your tube sizes are correct? Otherwise I would back track to the truck squaring and make sure all bearings are making contact on the trucks. I’m not a professional but seems like a good place to start.

It looks like it is all in the trucks to me.

Yes and no. You can tighten the trucks up a bit, but it really is not an issue as they drive independently. If we only used on stepper it would be a huge issue, but this is why we don’t need nema 23’s.

As long as you the bearings are all making good contact you are fine.

Cool! Thanks for the responses! I’ll work on it tonight.

When I was checking for bearing contact on the trucks I followed the directions as best as I could. I’d hold the tubing at about a 45 degree angle and see how the trucks would roll. I tightened them so that they would roll at a slower steady pace for all 4.

Pretty sure I solved the issue. The clamps holding the tubing on top of the trucks were definitely not tight enough. Once tightened appropriately, a lot of the slop was gone. I then systematically checked each bearing had contact with the tubing. Now the only play I have is if I were to force it really.

On to the belts!!

Yes. As long as the heads aren’t large enough to cause any shorts. The vias and the little pads around screw holes are ground.

Awesome thanks!

I started wiring everything up to the Rambo v1.4. Here’s a photo. I am new to this so if you see something off, please let me know.

I read and then reread everything. Seems simple but at the same time easy to over look if not paying attention.

I am using dual end stops. Also does it matter which x or y stepper motor is plugged into x1 and y1? I haven’t plugged in Z yet as I need to shorten the wires by a lot.

Also is my power input correct?

I feel like maybe I should rewire and just do series wiring for now…

I have the harnesses so shouldn’t take much to Get her going…

Pretty sure it only matters during homing. X1 stepper has to be coordinated with the X1 endstop, etc. I’m PRETTY sure that as long as the stepper you want pushes back, it doesn’t technically matter which is which, but it will be a lot easier to keep track of if it matches the documentation.

Started rewiring and using series kit

Is there a pen mount for the primo version yet?

The pen mount should be attached to the universal mount.