Today I was thinking about a way to obtain precision in the range of 0.01-0.02mm (0.0005" to 0.001") while taking as many sources of inaccuracy into account as possible. That includes skewness, belt stretch, skipping steps, etc.

I thought about delta 3d printers (like a Kossel, Rostock, etc). There are three towers. Each has a carriage that is moved up and down by a stepper. Together they position the extruder at any point in 3 dimensions. Then I thought, what if I could do the reverse? Attach the ends of the arms (that normally hold the extruder) to the router. By moving the router, the arms will move up and down. If you replace the steppers with rotary encoders, you can measure the position of each of the carriages, and then compute the exact position of the router in 3 dimensions.

The towers would have to be pretty far apart and pretty tall probably. Everything would have to be built really accurately. So it’s probably not feasible to build it exactly like a reverse delta printer.

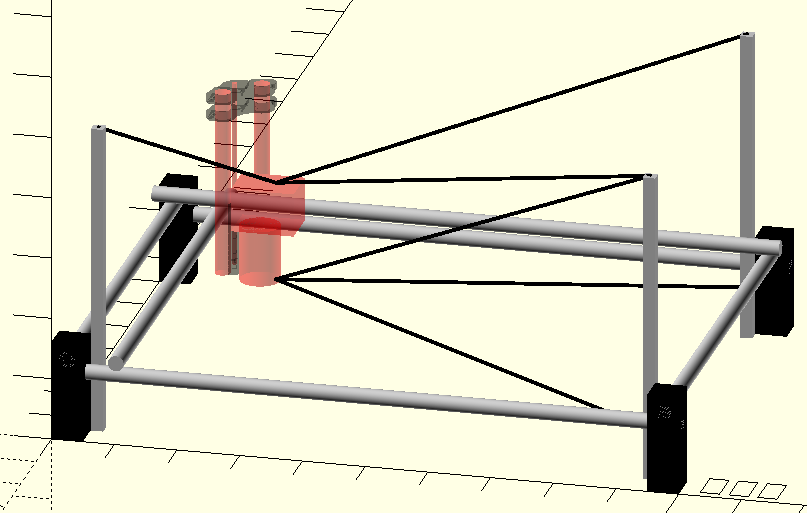

So then I thought, what if I attach a GT2 belt to the router, and attach the other end to a tape-measure-like spring loaded pulley and put the rotary encoder on the belt close to that pulley? When the router moves, the belt rolls up and unrolls as needed. The encoder measures the distance from itself to the router. Put three such belts on the router and you can measure in 3D.

This system works like a closed-loop stepper system. But it has the advantage that it can be completely independent from the MPCNC (or whatever you attach it to). It is not affected by sideways force on the end mill. Belt stretch doesn’t affect it (aside from a slight stretch in the measurement belt, but the tape measure would hold it at a similar tension at all times). Frame and gantry non-squareness are automatically corrected for.

If you have a aluminum block of known dimensions, you can probe it and that would allow you to accurately convert the measurement system’s orientation to your workspace orientation.

One thing this system would not “see” is tilt of the gantry (and therefore end mill) due to sideways forces.

What do you guys think? Is there any merit to the idea? Any obvious problems I have overlooked?