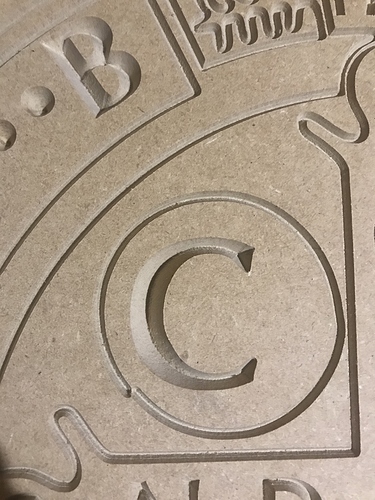

Would you guys say these sloppy circles are due to having “Use arcs” checked in post processor? Running tests later but thought someone might have some input

This is very unlikely to be arcs. It looks like backlash in the x direction. Backlash of this magnitude (making certain assumptions about the size of the cut and workpiece) are likely to be loose grub screws on one or both of the motor pulleys. That would be the first place to check.

Aint you a wizard??

Workpiece is 18 square inches and the circles pictured are roughly 3in in diameter. I’ll pay attention to my X axis tonight. I’m thinking my Y plates could be creeping and not rolling perfectly straight? (Lowrider 2 machine)…

UPDATE: I tried a smaller version at 12 square inches and the problem got even worse!! Finished piece isn’t even usable. Material is just 3/4" MDF. I know plenty of people have awesome working machines but I’m so close to throwing in the towel. This build was a great challenge and launched me into learning so much, but maybe I’m just over my head.

Don’t! There are so many extremely helpful and knowledgeable people here, who are more than willing to aid you.

Check those screws, they bite us more often than they have the right to.

Getting worse when it is smaller is even better evidence that it is backlash. Hopefully it is those grub screws and you will be cruising soon.

Wow, how the hell did you guys nail it on the head like that?? Sorry for the sob story earlier, but looks like somehow the grub screws were in fact a little loose on my X stepper pulley. Dang, if any of you are ever in Kansas City (KS), I owe you a beer!

I have had it bite twice lock tite is my friend

We know a thing or two, because we’ve seen a thing or two.

Happened to me too. I did myself some files in FS 360 to test it.

Spent an entire weekend on it until this threw up an answer.

test files for x axis grub screw.zip (42.8 KB)

Glad it’s only backlash because everything else looks great. What are you using for CAM? Nice v carving

Thanks! I’m using Fusion 360 and a 60 degree bit (well, taper angle is really 30 degree).

Darn, I was afraid of that. I am avoiding Fusion 360. I use Onshape so much for my 3D printing, I don’t want to give up that for the CAM of Fusion 360. I have worked through a whole part and was successful in it once, but I’m just not ready to invest the time yet.

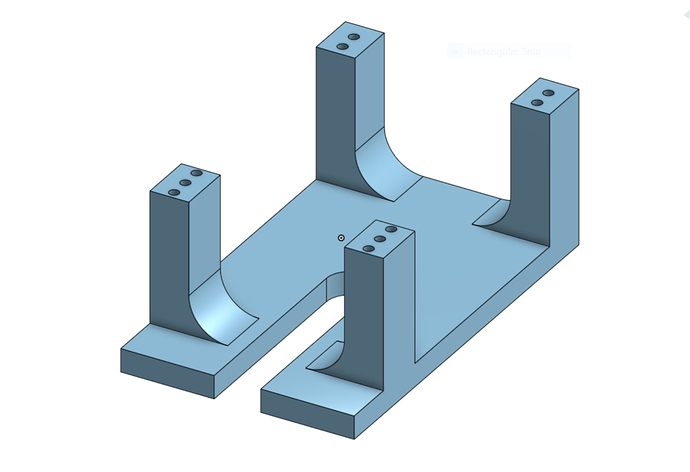

Right now I’m doing a lot of electronics work and use my laser cutter/engraver and my 3D printers to make parts, like this ESP32 microcontroller socket.

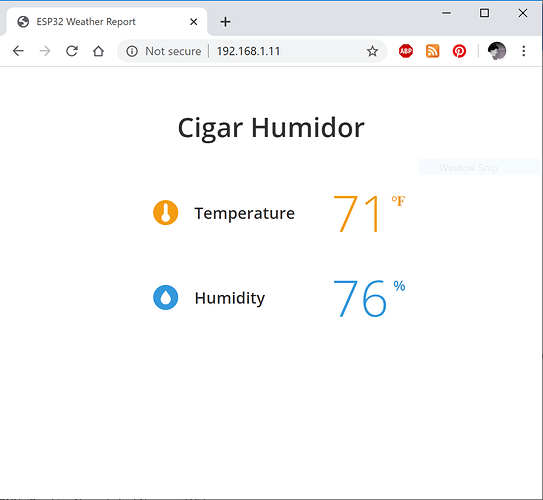

I’ve been working up temp and humidity sensors to remotely monitor a cigar humidor and for my filament dry boxes for PETG. Once I have the electronics all set, I’ll go back to the CNC to make the actual humidor box.

Just recharged the cartridge so is hasn’t balanced out yet.

I can get some decent v-carves with EstlCAM, but I still haven’t gotten it totally worked out with size of lettering and depth of cut in respect to the bit. I just have used the 3mm bits, but I have a 6mm bit that I want to check out. Takes work getting it dialed in, but once you do, you can really make some nice stuff like yours.