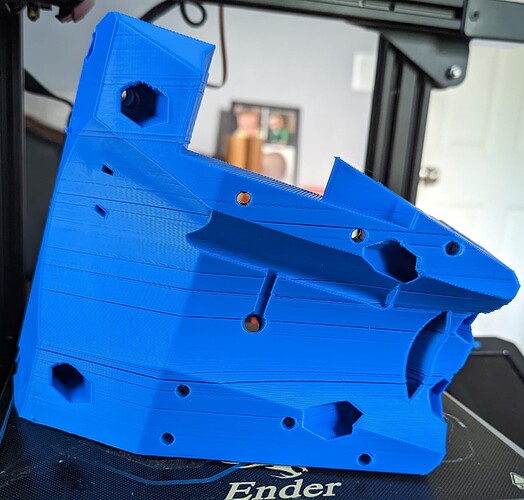

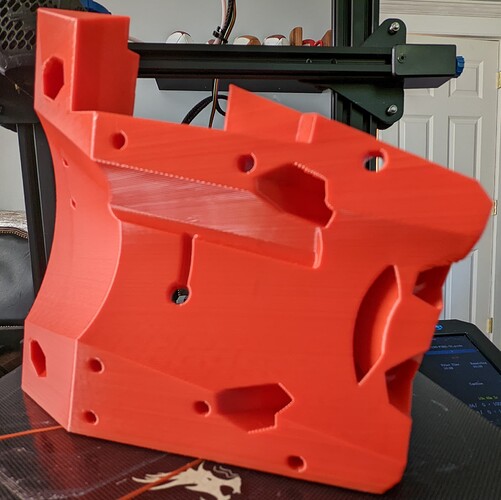

Well core finished. To make a short story long, it came out being a cross between pretty & ugly. In other words, pretty ugly. And my comment earlier in the day was going to come back and bite me firmly in my Tuchus. With yesterday being a work day, although the printer was 6 feet from my desk, I really wasn’t focused on it, other than to look over at it now and then. By the time I noticed the problems, I figured what the heck, might as well finish, boost the temp, slow down a bit, let’s see what happens, what’s a little more wasted corn starch. Besides I wanted to hold in my hands what many have said is a fantastic piece of engineering. They were right.

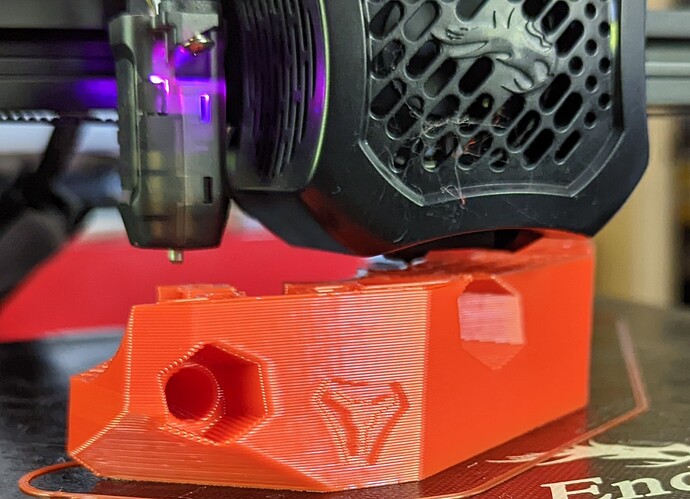

Like most catastrophes, a simple issue the other night, lead to the demise. While printing something goofy, that needed supports, even though the designer said no it didn’t, my heat sock got knocked off by the spaghetti. Now mind you, my first ender had no such thing to my recollection, so after trying to put it back on, only to have it fall off again, I paid it no mind. Wrong answer kemosabe.

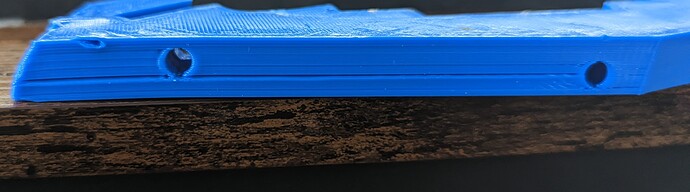

17 hours in, and 20 minutes from completion, I got my first ever in my life thermal runaway warning. After shutting down, and restarting, the print finished (wasn’t expecting that, thank you professional firmware), flaws and all. I tried flexing it a few times, no pop, crackle, snap sounds, “seems” solid, I told myself. I tried to break it, really I did, couldn’t, maybeeeeee it will be ok. This morning I went searching for answers, with the knowledge that no, it won’t be ok you idiot, and yes, we will be trying this experiment again. Shout out to @Ryan over how many cores must you have printed while developing the LR3, patience of Job, that man.

- Underextrusion

- Too fast printing speed

- Abrupt Temperature Changes

- Thermal Runaway

A rubber sock? Most of this can be attributed to the darn sock? (or so I hope). I must admit that after the thermal error, I backed off the speed by 10% and sent the temp back to what it was, and the print looked a tiny, tiny bit nicer and a whole lot more uniform, either that, or I am good at lying to myself. Thanks to amazon, new socks and nozzles (going up to .5 or .6) will be here today. I’m telling myself I really didn’t want a blue core anyway, and everything is going to be all right. Nothing wrong with learning a lesson and a dry run. Anyone want a deal on a never used, might be ok, probably won’t, core?

![]()