I had a couple of problems working with hard aluminium (AW-7075) using my PRIMO. During miling the spindle/z-axis lifted in steps of ca. 1/10mm and depending of the deepth sometimes up to 0, with normal miling but also trochoidal.

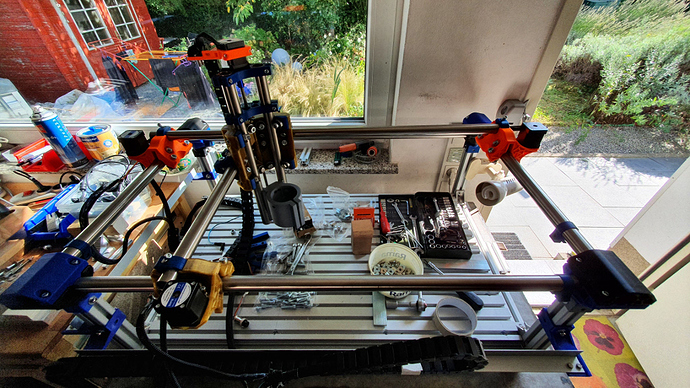

So I have modified a couple of things at my PRIMO.

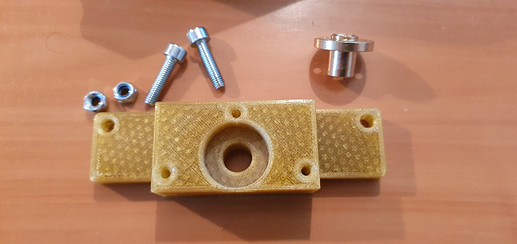

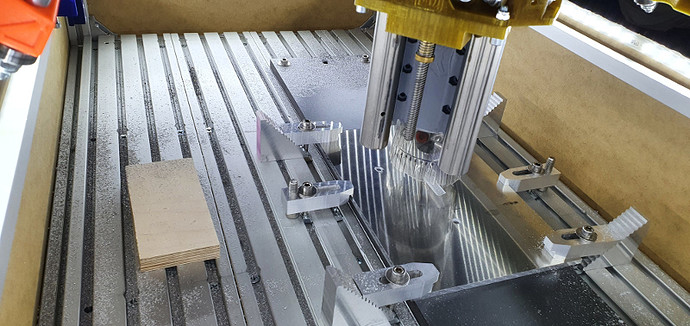

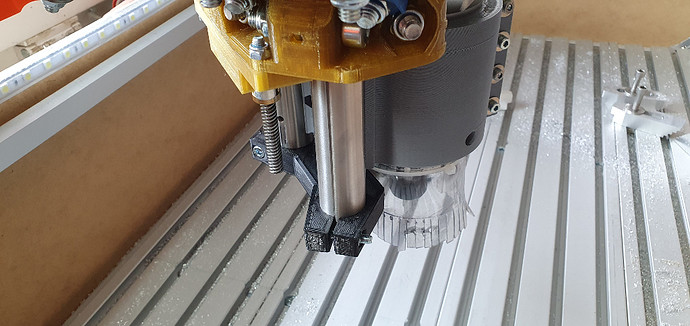

Additional stabilizer / clamping block for thread rod nut

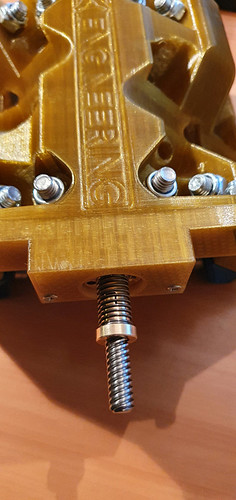

First I realized a new stabilizer or call it clamping block for the thread rod. Mine is a T8x8 2mm, so standard!

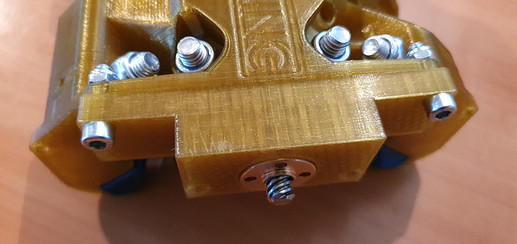

This clamping block will be installed at the bottom of the core and keep another nut.

I have designed the block in a way to use the standard holes at the core bottom for screws but also added some holes for other screws (3x30mm) to fix the block at the core. The position of the holes are chosen in a way that there is enough material at core side.

With that 2nd nut you are able to fix the thread rod in a very flexible way that it will not “dance” or “swing” while working with hard materials or if your feedrate in x- or y-direction or even worst in z-direction is too high.

Especially in z-direction e.g. diving into aluminium, I had problems using feedrates of more than 100mm/min. With this addition, I dive into the material with 300-400mm/min (Helical drill with a 3mm drill) without any problems and you can hear that the spindle is not going to vibrate anymore!

I also changed from the normal nut to a anti backlash nut which is even better to handle vibrations.

Really, it is a completly different/new/enhanced way to work, I couldn’t imagine that such an easy addition would have such impacts.

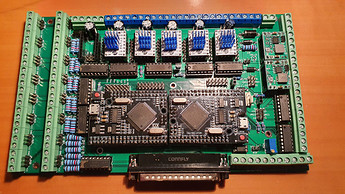

New drivers for my board (TMC2209 V3)

I am using a board based on Arduino Mega with drivers for each stepper. I started with DRV8825 and changed the drivers to TMC2209 V3 (256 Microsteps, 2A).

The TMC2209 have Vref of 1.0V to 1.1V but they work extremly silent and they do not get hot! Even the steppers keep really cold after working for hours!

Difference to the DRV8825:

- the steppers will run invers, so turn your cable at the driver or change config “revert direction” (typically) Estlcam

- the driver starts at 1/8 so min. config is 1.600 steps per revolution

Only disadvantages: Price is even higher than DRV8825 and the driver is really sensitive. Disconnecting the stepper on a running board will directly kill the driver! No chance!

That’s it!

Alltogether … I can really recommend using it.

And it results in NO lifts and NO losses.

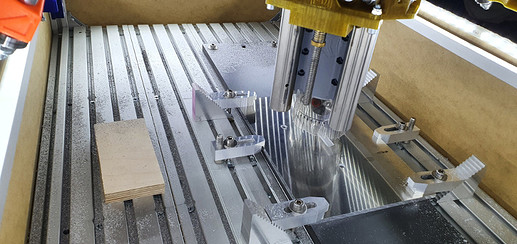

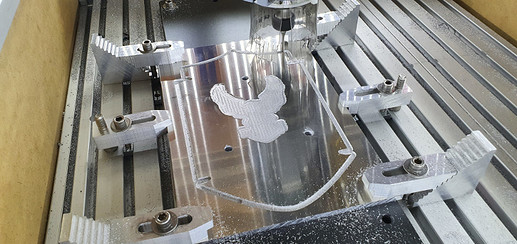

And here the “Final” at a “cool bike”

Ciao

DJ