Hello I’m new to the whole CNC world. I just ordered the kit to begin my build. What is the largest cutter for flatting and spindle size in kw that will that work on the low rider.I want to go with a spindle and not a router (noise) I building one to work on live edge wood. Oak, Maple, Walnut. I want to flatten and then carve on it. Slabs are 2.5 to 3.5 inches thick.

Thanks for any advice.

In terms of physical size, the “finishing routers” like the Dewalt and Makita are most common. To use a larger router you simply need to adapt the mount plate design.

In terms of mass, I have used a 3 kg full-size router without issue but more weight means more work for all of the steppers to move around that mass and its inertia. I’m much happier with my little Makita.

In terms of power, that’s up to your power supply.

For flattening I use a 40 mm slotting mill that does the job nicely and quickly.

The noise from the small finishing routers isn’t bad. Most of the noise comes from the integrated cooling fan blades. If you use a vacuum it will be much louder.

First welcome aboard. I think you’ll have a lot of fun here and with your new cnc when it gets going.

Short of enclosing everything, the cnc’s going to make noise one way or another. Less is less granted but it’s never going to be quiet. I’d be surprised if there weren’t some sound level tests comparing 611 vs spindle to give you something more empirical. We all seem to like details and info around here so I’m sure someone’s covered it in the hobby cnc space. The trim routers are cheeeeep!

Not to dissuade you from using the LR2 for planing but if I expected to be doing a lot of planing I’d be looking around for a planer to use in conjunction with the cnc. The main reason I say this is for speed, it takes a long time to cover every square mm of a board with a 40mm bit, where a planer could handle it in seconds. The piece size you don’t mention but what you’re intending to do for slabs may be beyond the typical 12-15" width of lots of the common planers though.

Just some ideas.

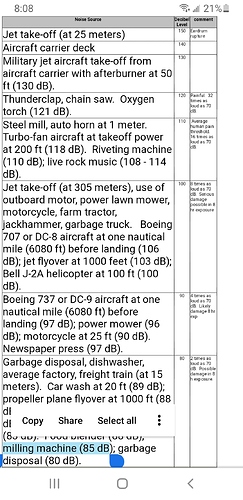

I second the thoughts on Spindle vs Router for noise. When cutting, both the spindle and router would make you want to wear hearing protection. Most of the noise produced is high frequency thus doesn’t penetrate/travel far.

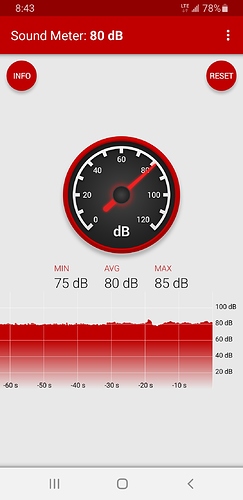

I’m cutting right now and figured I’d help quantify a bit, a free sound app suggests cutting with my lr2, Dewalt router and shop vac dust collection is 80db on avg.

I was looking at spindles and they don’t seem to post the weight of them. I’m worried about overloading the rails. If anybody is using a spindle on the LR2. What setup are you using?

I find that number difficult to believe. I’m hard of hearing due to heavy scarring of the ear drums and loud music (turn it up so I can hear it over the scarring), and my LR2 alone is loud enough to hurt without hearing protection. Add my shop vac, and I can’t be in the garage while they run unless I wear my over ear protection.

I have a true dB meter and my router and vac together are between 100 and 110 on average. It’s the primary reason I am switching over to a 500w DC Brushless spindle. What speed do you run your router at with the variable speed control? That can make a big difference.

The environment will make a big difference as well, if the walls of your garage reflect sound rather than absorbing it, that could account for 20db.

With no point of reference to argue with 100db seems extremely loud, and I would not characterize the lr2 that way. It’s completely subjective so consider the measurements simply as what they are. The app was called sound meter and i ran it from my android phone standing directly in front of the machine. I run my cnc inside an insulated and wood pannelled space.

I do remember testing my shop vac alone before with a different sound measuring app and if I recall it hit in the '70s as I made an enclosure for it at the time that was short lived.

I usually run my 611 around 2-3 depending on the noise it’s making.

That’s fair. I’ll do some app testing alongside my dB meter today just to see if there are any discrepancies.

My space is uninsulated and does not have drywall/paneling. I recognize that this may be part of the issue. I also tend to run my router at a higher speed setting which increases the noise.

So if anybody is using a spindle on a LR2 what kind are you using

I am curious as quieter is always appealing. I’ve been around enough of these maker forums and garage guy things to have heard all the pleas from old timers with hearing loss to quite happily always protect my own ears. I don’t imagine there is a way around that with my setup short of having the vacuum in another room, and the cnc in an enclosure. Neither would be things I’d look at doing now.

My vacuum is one of the worst offenders in this case. I will be building a plywood enclosure for it with an air baffle and foam filter exhaust. I run a mini cyclone collector above it, but with the vacuum enclosed it would definitely be quieter. I would ideally prefer a true dust collector setup as it would be considerably quieter.

I recently plumbed a full dust collection system in my shop, including to the Lowrider.

The sound level is so much more bearable than the shop vac. While I certainly wouldn’t call is quiet:

- It is much quieter. Even standing next to it you can have a conversation without yelling.

- The dust collector is in the corner of the room, so its further from me.

- Most importantly, the quality of the sound is much better. The shop vac emits many high-pitched frequencies. The dust collector emits a couple of low frequencies.

Nonetheless, I always wear hearing protection. I’ve already lost a lot of my hearing, don’t want to lose more.