Anyone use any of those plaining bits on a mdf spoil board. Just having my spoil board laying against the wall as I started my build for table, it’s already curved to all hell. I’m sure with screws and my support brackets it will tie down. Seeing as a 4x8 isn’t going through a plainer that I have access too. I figure any squaring issues on my work surface spoil board could be plained to the 2x4 imperfection by planing with a plaining bit just let it run on Gcode through its full axis. Any suggestions ?

I use one of these.

https://www.amazon.com/Amana-Spoilboard-Surfacing-Rabbeting-Flycutter/dp/B016O7U97G/ref=sr_1_6?dchild=1&keywords=amana+tool+spoilboard&qid=1591012418&s=power-hand-tools&sr=1-6

I am in Canada so should be cheaper in the US. Also, I am certain the you get what you pay for but I used this on MDF and it was okay. I cant remember my DOC but I am always cautious (like maybe .20 mm every pass).

-

I bought (Bottom Cleaning Router Bit 1 Inch 1/4 Inch Shank, for CNC or Table, Carbide Tipped, Surface Planing, Flattening, Grinding - Woodworking Milling Cutter). Of course, no longer available but I paid $8.00 for it.

-

I see amazon “suggests” (MeiBoAll Spoilboard Bit, CNC Spoilboard Surfacing Bit 1/4 Inch Shank 1 Inch Cut Diameter 3 Flute Slab Flattening Router Bit Carbide Planer Surfacing Router Bit Edge Treatment Grooving Router Bits)

Not sure that helps. I have only surfaced once and thought that a cheap bit (even if I use it once) should do fine on MDF. However, I have very limited experience on this. Others may disagree.

Awesome, that is exactly what I was looking at. Well the 25 version 😬. I’m all about spending on the right tool, and maintaining it. But might as well go for a cheapy, until I get the hang of feeds and speeds. Don’t want to snap 100 bucks on the first pass.

Tracking order, got the variety pack Of bits from the shop, series cables and the little v1 z homing sensor arriving today, my 1/8 collets arrived yesterday from amazon.

Using the dremel bit to cut out the wood plates by hand really struggled. Going to call up a local source today for the Stainless tube today. We just got out of corona lockdown today , but now we got an even worst curfew with all the protesting going on… couldn’t even order a pizza after 7:00pm yesterday .

Thanks guys

I’ve never tried one on wood but have used a similarly configured (minus the center drill) tool on aluminum (mill, not the MPCNC) and it worked great.

Of course something with two cutting bits equally spaced from center would be much better for balance, a router at full speed with only one cutter would likely shake itself apart.

The following came up in a search, I have no idea why it’s labeled a ‘wrench’ as the pic sure looks like a flycutter with 2 replaceable bits: https://ballewsaw.com/onsrud-91-136-spoilboard-wrench.html?utm_source=google_shopping&gclid=EAIaIQobChMIuefTmOHg6QIVCrbICh27Bwu7EAQYBSABEgIKy_D_BwE

I’ve been using freud 16-106

I can’t remember if I got that one off amazon or home depot, but it’s cost effective and sturdy.

My spendy one had replaceable cutters, there’s four cutting surfaces per blade. So far I haven’t hit any metal, but I can see accidently surfacing off a broken screw or something. You can’t really sharpen the other kind, so when they wear out you have to buy the whole thing over again.

@B-26 No way in hell I’d put somehting like that in a router! I barely like putting one in my drill press!

I might try it in a hand-held router first as long as it had speed control. Sometimes things surprise you.

Make sure you’re wearing a kevlar vest if you do.

That second one is called that because of the shape I think.

I’m going to have to agree with @barry99705 that circle cutter will be dangerous in anything handheld, as well as in a router in any configuration. Quote from the HD listing…

For use in a drill press only - 500 RPM max

I don’t know, I’ve heard trying to obtain a Kevlar vest attracts black Suburbans to your driveway. ![]()

Yeah, that was a bad example, it’s really a hole cutter. I was thinking of a fly-cutter that generally has two bits equidistant from the center and no center drill. I have a friend who made one with an aluminum bar holding two cutters about 5"-6" apart that he uses to resurface aluminum cylinder heads, does a beautiful job. I was thinking something similar if smaller might work well on wood.

That sounds like the wrong scale to me. We are talking about surfacing wood, and anything bigger than an inch is enormous. Keep in mind, you don’t want the spoil board perfectly flat, you want it perfectly equidistant from the XY plane. Spinning up a 6" fly cutter is a good way to have a bad day, and the result will be a big stair step in your spoil board (if you stay out of the hospital).

Wouldn’t it have to be perfectly flat to be equidistant from a plane?

What I’m calling the XY plane is where the bit would travel if it kept the same Z, but changed its XY. Just imagine a really heavy router and it sagging in the middle. You want that sag in the spoil board so a piece of MDF that settles onto the spoil board will have the top surface at the same Z.

When I imagine that I imagine that sag shifting its location as the XY changes, but if the spoilboard was flat it would remain equidistant from that sagging router, wouldn’t it? Or are you saying when we plane the spoilboard we automatically plane it to conform with that sagging router path? I missed that concept first time around.

https://www.amazon.com/gp/product/B071748JQN/ref=ppx_yo_dt_b_asin_title_o02_s00?ie=UTF8&psc=1

Here is the bit I purchased and finally used today.

Since you’re using the router to surface it, the flex due to the router weight will be compensated for (it really is pretty small, in general, but it does get compensated for). As the router moves closer to the corners, it will raise up, because it is stiffer there.

Didn’t Jamie measure his in the center and it was like a thou or two? For wood, that’s really not a lot.

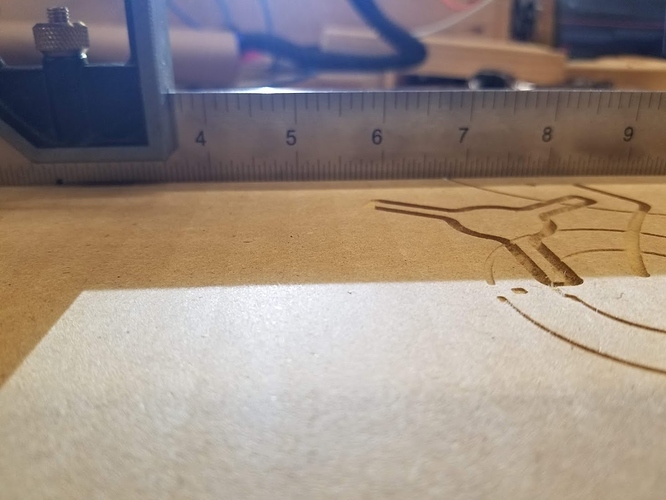

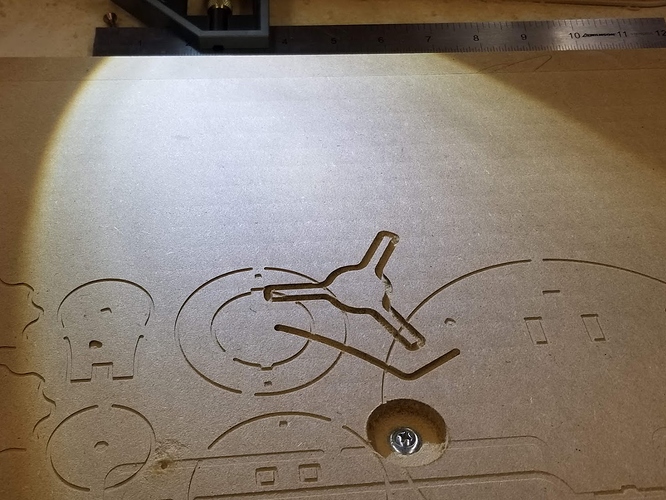

Here’s my spoilboard after I got primo put together and surfaced with the cutter I linked to up top. There’s a bright flashlight behind the steel ruler. I figure if I can’t see any light, it’s flat enough.

You can see the swirl, but can barely feel the lines. I think it’s mostly just the texture of the mdf is different depending which direction the cutters traveled over it.

Here’s the video. Had to run it past Ryan first.