All of this information is in my build thread also, but I’m getting questions and thought others would like to have some answers in a more easily located place.

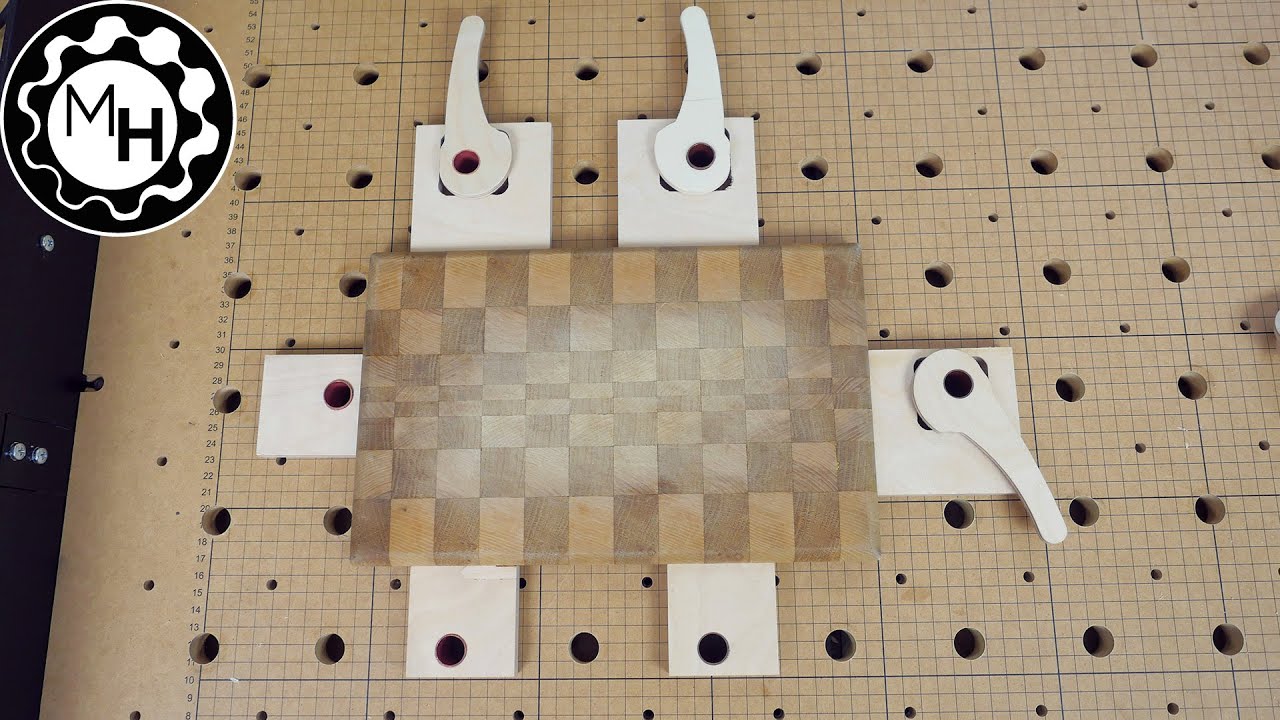

My camlock hold downs are based off of the Hornberger clamps from his youtube channel here:

I modified them to accept 1/4-20 bolts. I did this in Fusion360 by importing his dxf file and filling in his holes and putting in new smaller ones. I only did this on the camlock part. After cutting the parts out on the CNC and gluing the camlock part to the handle, I used a drill and forstner bit to copy the hole from the camlock through the handle.

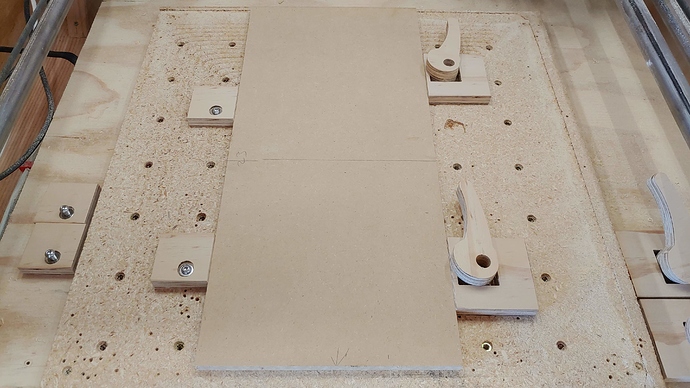

My spoilboard has matching 1/4-20 threaded inserts mounted in a grid 80mm x 80mm. This allows me to fit 48 hold down points on my 23"x23" cut size.

So far it appears to be working pretty well. I’m still only cutting my first cut with it, but everything seems to be holding pretty steady. I’m not hearing any chatter from the material moving.

For other F360 users, my design is here: