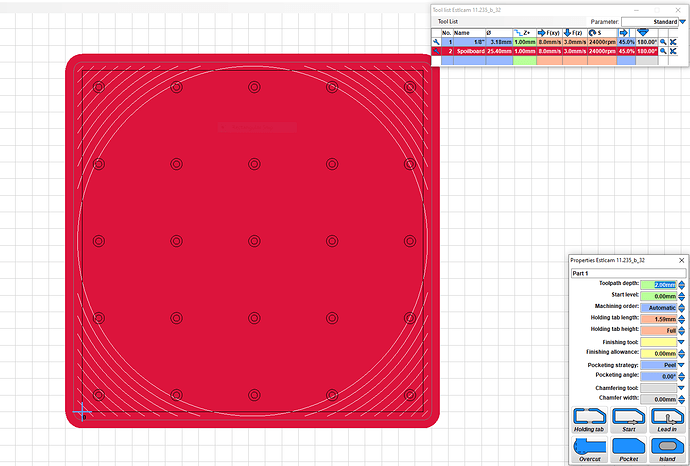

Hi guys, trying to wrap my head around the whole feeds/speeds/stepover tool settings.

I’m trying to surface my spoilboard (3/4" MDF) with this bit:

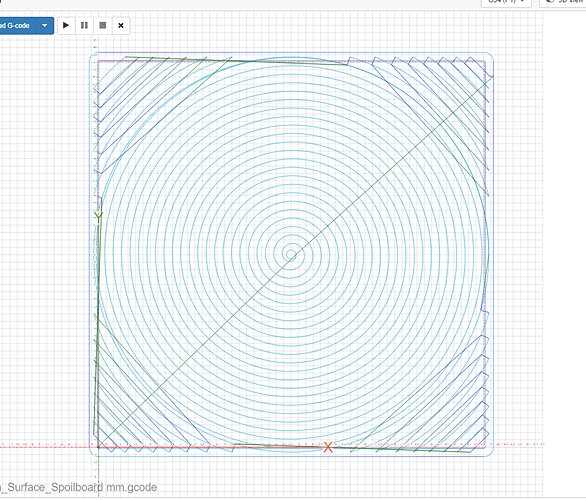

You can see that when I separately run a rectangle around the perimeter, the finish is perfect. Using the same bit/settings, when I try to pocket out, there are a couple things I notice. I stopped the job and what you see is only during the first pass (so -1mm on the Z):

-

The upper left side (MDF is uneven and this area is deeper), the bit is just skimming the surface and it looks like it is burning.

-

The right side has noticeable rings. This would be an issue with my stepover setting?

Both of these issues are easily solved with a palm sander and light sanding with 80-grit, not the ideal solution

Here is a photo of my issue, my setup in Estlcam and what the toolpath looks like in CNCjs.

Thank you for any help with understanding the tool settings – or something else I may be misunderstanding/doing wrong!