Hi everybody. Since a couple years I have set a stop in building my sailboat model to organize my workshop. The main reason I am slow are my health problems. But impacting is that working to improve my workshop has become a purpose by itself.

The start of this work was due to my tower mill getting damaged and the chaos in my workshop made it impossible to make the repair by myself.

So I did purchase the table saw Bosch Professional GTS 10 XC and did expand it by building a router table using the Triton tra001. These machines generate so much dust and chips that I decided to build a dust absortion system that uses a cyclone and an industrial vacuum cleaner.

The calibration of the circular table saw and the router table extension used a lot 3D printed stuff, that I decided to buy a Creality Ender 5 Plus printer. Watching videos from Kersey Fabrications and others and trying to educate myself abot 3D printing becoming 3D printing a hobby by itself and I have purchased 2 BTT SKR PRO V1.2. I have purchased these 2 boards because I found out for myself that both, 3D printing and CNC work using G-Code to do their jobs.

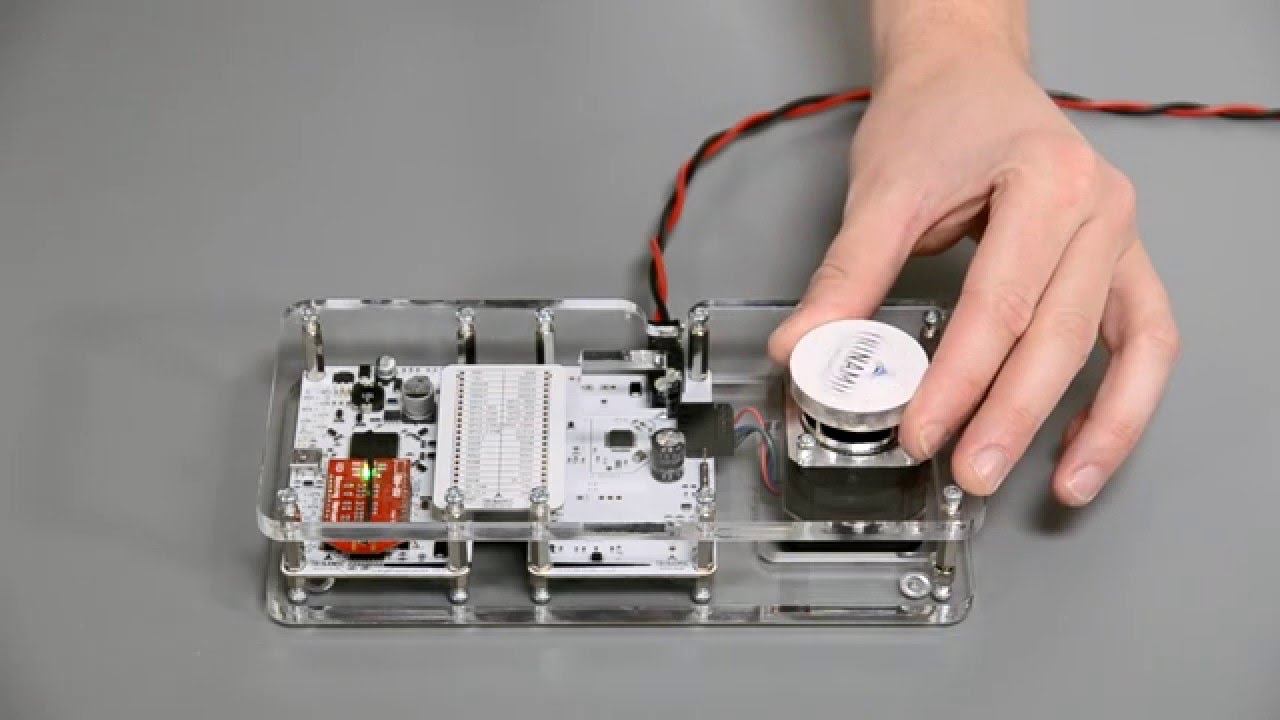

During my years working in the semiconductor industry making and using electronics in my hobbies to do the things my way. So, close to a decade I decided to use stepper motors instead of winches in my model sailboat and driving them usinc Trinamic stepper motor drivers. Their evaluation kits and their IDE enable you to learn a lot about the inner workings of stepper motors and how the Trinamic ICs provide valuable functionalities.

So studying the details of 3D printers I did notice that the 3D printer ecosystem shows an incredible amount of ignorance about stepper motors and an incredible arrogance. I know this a pretty hard judgement and I have received valuable responces from a few.

I know and you have the full and justified right to demand my justification.

The issues show themself in many topics:

- Stepper motors used in 3D printer do not have the plate that shows the nominal values for current and voltage. Also missing is the value for the holding torque. Stepper motors usually show this important information. It seems that NEMA17 sized stepper motors share this. Only going to the websites of serious manufacturers of stepper motors show this data. Why is this information so important.

The maximum torque of a stepper motor is exclusively there when the nominal current is flowing through its coils. This current flows only when the applied voltage is the effective voltage and this only true when the value of the induced voltage is ZERO.

Veffective = Vapplied + (-Vinduced)

The absolute value of the induced voltage is the higher and the faster the voltage changes that makes the current flow through the coils.

So, the faster a stepper motor makes its steps, the shorter is the time the voltage changes its values. This is why I decided to buy, additionally a Meanwell 600W 48 VDC power supply to be fed to the stepper motors driven by the SilentStepSticks driver boards.

You might not believe the aggresive and personally offensive responses I got in all 3D printing forums. But you might also not believe huw fast this incompetent aggressive forum membeds disappeared when I quoted an entry from the FAQ section at the Trinamic website explained why stepper motors are usually operated by applying a voltage of up to 20x the value of the nominal voltage value.

When applying voltage, as I will do, 48 VDC, the effective voltage will not drop due to the induced voltage. A stepper motor driver will limit the current value to nominal current using PWM.

-

A more performant stepper motor is one that achieves its nominal torque with the lowest nominal voltage. Why. Because this means the cables in its coil can handle more current. In my sailboat model I use stepper motors with a nominal voltage value of 3.6 VDC. The stepper motors are fed from a battery pac that has 12 LiFePO4 battery cells connected inseries and that fully loaded supply close to 40 VDC and when they have to be recharged still 24 VDC.

-

When studying the videos from Kersey Fabrications 2 aspects become evident to me. Please, I am aware of that speed of printing are the result multiple factors that have interdependancies. In another forum I read the analogy to dancing.

One fully self explaining is that a controller board has to be able to process all G-Codes that are due between steps and that stepper motors need to have the torque required to move from one step to the next for step loses not to take place.

.

.