Hey all.

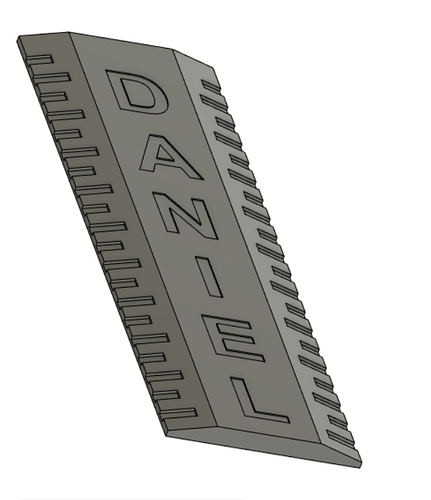

I’m looking to make the attached design its 120cm tall and 25 cm wide ruler that I want to use as a decoration for measuring my nephew. As you’ll see it’s tapered on the edges and also I’ve got the stepped marked. Is this something that ESTL cam can manage or will I need a more powerful post processor like Fusion?

Estlcam can handle that, but I’m not certain how to make it skip the parts that don’t need to be milled.

Honestly though, that is going to be like a 40 hour job and I don’t think it will turn out that great.

Can you split it into 3 parts so the angled face can be done on a bandsaw or table saw?

Can you make the letters embossed out? Then you could cut them out and glue them down.

Depending on the depth, it might even be possible to make it out of sheet goods and have it come out looking a lot better.

I’m wondering if you could cut the side bevels on a table saw or other tool (as @jeffeb3) suggests, then build a fixture that would hold those sides parallel to the router to carve them. You’d do the carving as 3 jobs, the center, then each side. Since the side angle is the same a single fixture should be able to hold for both sides, maybe mirroring the cut job?

Yea I thought of making a triangular piece of timer that would lift the workpiece at the angle the taper is at and then I could just mill it flat and do it as 3 seperate jobs. If the jig was square it would allow me to do the two tapered pieces and the metric/ imperial sides of the ruler and then just a flat milled surface and as suggested add the pieces on as embossed pieces or maybe a carve.

I’d just love to be able to do it all in 1 job instead of multiple where possible but I do agree the cut quality of the taper would be WAY better.

And the job time is proportional to the distance the bit has to move, which is 120cm long, but also several passes to reach that depth and 20-30 passes to cover that area. I would be interested to see the job time estimate. I bet it is over a day.