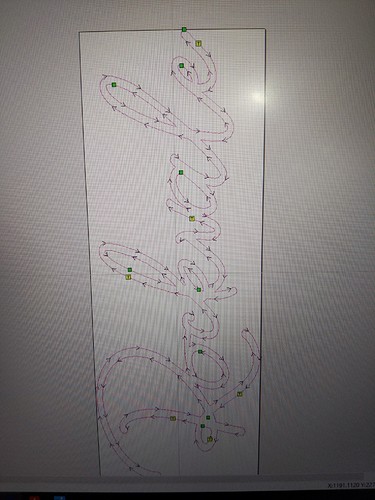

So I am doing a sign in some fancy cursive for a friend. I was wondering about tabs in loops like in the O, K, L, etc. Do you guys add tabs in those sections even though those pieces are going to be completely cut out? I didn’t know if it would be prudent to add tabs there or not.

I wasn’t sure if the waste piece inside the loops would cause issues when finishing that part of the cut out. I am attaching the picture. Thanks!

How big is this going to be? If you use the painters tape and super glue hold down method, you don’t need tabs. But it might be too big? Or perhaps not?

Much like Turbinbjorn said, if you are otherwise securing those cutouts, you should have no problems. If it’s really big, you could even drive screws through those pieces to secure them to your spoilboard. If it’s small enough, run a pocketing job first to remove the cutouts as chips, rather than just a single channel cutaway. If it’s somewhere in between, maybe consider a mix. I’d also be concerned with the inside of the R getting loose and wibbly-wobbly. You probably want to make sure it’s secured.

That looks like you might just be vcarving the line? I say that becuse the tool path is on the line, carving is typically inside it, parting is outside it.

If you are trying to “part” that it will give you options to pocket or use holding tabs.

If you are trying to “carve” it should give you options to either sink in the letters or leave them raised and sink the exterior of the sign. Either way not cut all the way through.

It’s a risk to let those pieces loose. They usually don’t cause a problem, but they can get stuck and make the router lose steps, which would probably ruin the piece after it has done almost all the work  . If it is secured another way, like with tape across the bottom (the tape needs to be held down in that area, or you’re likely to cut through it and still have a problem). The suggestion for a screw in those parts is also a good one. On one project I made the screw holes in CAD first, and just let the machine tap them 2mm down, and then I came back with the drill/screws in those exact places before starting the job.

. If it is secured another way, like with tape across the bottom (the tape needs to be held down in that area, or you’re likely to cut through it and still have a problem). The suggestion for a screw in those parts is also a good one. On one project I made the screw holes in CAD first, and just let the machine tap them 2mm down, and then I came back with the drill/screws in those exact places before starting the job.

But I would probably just do the lazy thing and make short tabs, about half the thickness of the material. It takes two mins to clean up with a chisel and some sand paper.

Personally I’d check the time difference between hogging them out and cutting them out, then subtract some estimate of the time to clean up the tabs. I usually have enough to do in the garage that it makes sense for me to hog them out and save the manual time in favor of machine time because most of the stuff I need to do is NOT more cutting on the cnc…so it’s not in the way.

Sanding and finishing other stuff that the cnc can’t do is where I spend the time instead. Of course, this is specifically for the insides of letters and such. Cutting out a part is a little different.

Anyway, just how I think about it, and I’m not that smart.

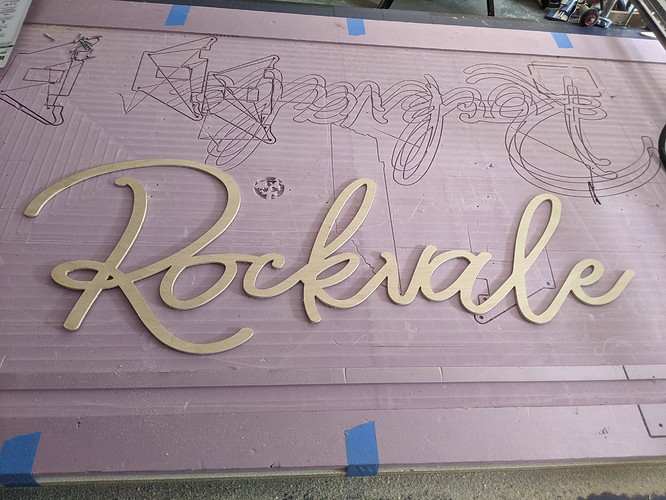

Thanks for the responses guys. I was doing a cutout. It did give me the option of tabs, but I just didn’t know how necessary they were in certain spots. I ended up using the tabs and spending the time sanding it down after it was done and it turned out great. I think the next time I am going to try pocketing the loops vs parting like I did this time just to see the difference in times as suggested.

That came out great!!!

That is a huge sign. The only one I might consider pocketing is the inner “e”. I would focus more on the smallest tabs possible. I tend to clean most of mine up with a sharp razor knife. 3mm high 4mm wide is what I used yesterday on 1/2" particle board.

I might give an eyeball to the short loop in the ‘k’ as well, maybe the small backloop in the ‘R’. And I concur, that is a sweet looking sign!

Good Call I didn’t even notice those!

Now, who tells him it was supposed to be “Rockdale”?

That turned out nice!