Mine is estimated at 28, but my machine runs faster than simplify3d’s estimates.

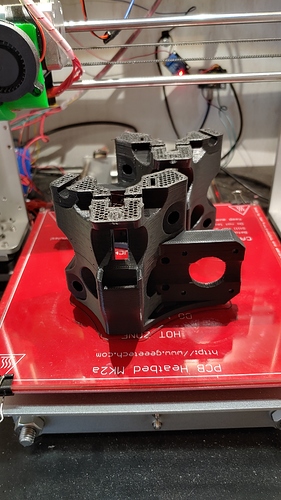

It’s all about the settings. I print at 0.2 (for hole size accuracy), with 4 perimeters (for strength) and 70% infill (as per instructions). One of the main things is that I use gyroid infill, which adds 10-15 hours more than if I had used rectilinear.

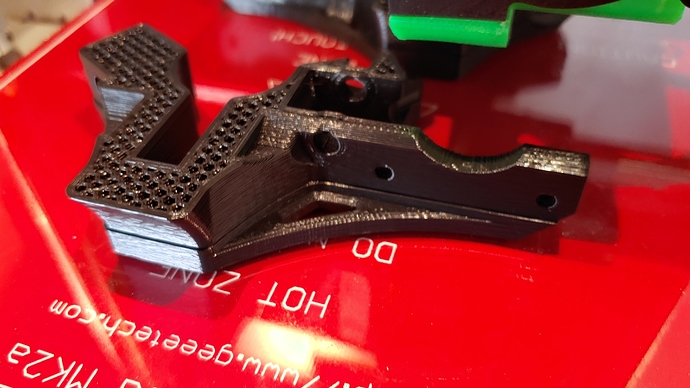

Failed print number 2.

Two upgrades I occasionally wish I’ve done to my printer are a bed leveler and a filament sensor.

I even considered swapping filament before starting this job, but then I was like, “nah, there’s enough bro.”

I feel your pain! That’s why I now have two printers, one with filament sensor and power loss recovery and one with nothing. I print small parts only on the second one. I have not had filament run out on me yet, but I did accidentally knock the power plug loose on a big print about 2/3rds thorugh the print. Power loss recovery worked like a charm.

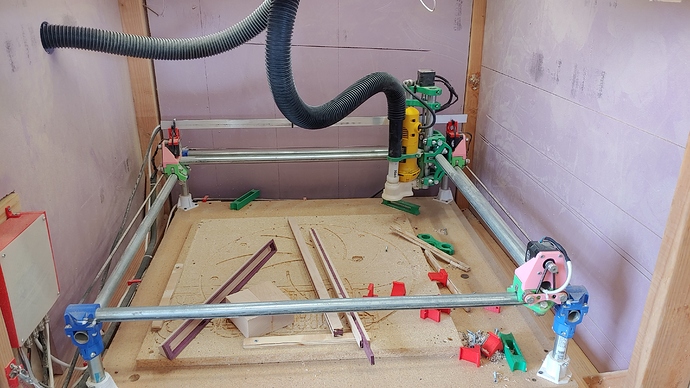

Last picture of the 525/burly hybrid.

525 trucks and corners, burly “core”

You’ve served me well my friend.

Curious if your enclosure walls were simply foam and if so, how effective were they for noise reduction?

1.5" foam layered on 1/4" ply. It didn’t help much with noise since I never put a door on it. I would occasionally rest another piece of foam on the front and that would help a little.

Looks like I might have had a small layer shift in the latest print. I don’t think it’s in a spot where it will affect anything.

Thanks for the reply! I’ve tabled my enclosure plans for a bit, still learning the machine and for the small cuts I’ve been doing I can live with ear-muffs and a handheld vacuum nozzle for the time being. I need to get more up to speed with software.

With gyroid you can cut the infill percent in half for the same strength. 70% gyroid is practically solid.

My tubing from jegs is in.

It could have been straighter. This is a picture with the other end held down.

Unfortunately that’s not how steel works. That is a bummer though.

- Octoprint

- CancelObjects and ExcludeRegion plugins

I get my jegs pipe tomorrow hoping it’s not to bent or banged up

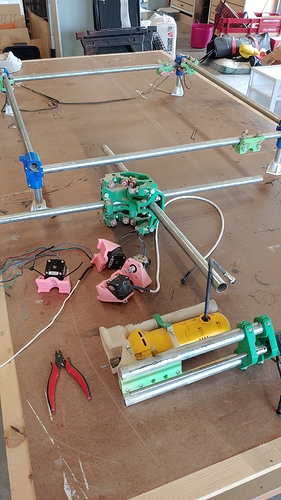

First set of trucks finished

we’re at 61:30 of total print time so far

If you look in the picture of the last post. You can see where the layer shifted.

I started the second set of trucks this morning and the layer shifted in the same spot again. This time worse.

I re-sliced the file, although I don’t think that’s it as the first set of trucks were perfect. I also disabled timeplapse and octolapse on the printer. Octolapse injects extra g-code to send the print head and table to a certain location to take the picture. Since the error happened in the exact same layer on both prints, I’m wondering if there’s something funny about the location and octolapse isn’t sending the print back to the exact same spot it left.

We’ll see if this set of trucks comes out better.