I’ve completed my build (at least for now) and it was a really engaging project. I’m really impressed with the overall design of the gantry. I added my own designs for the electronics enclosures, created brackets for implementing the “tape measure trick” to manage the wire routing, and designed my own version of a vacuum system NOT mounted on the ‘Z’ axis.  In addition, because of my limited space, I built a fold-up, roll away table for it. During the process, I was amazed to find answers to all of my questions on the forum. How cool is that! So, thanks to everybody that contributed. Now I gotta go make some stuff.

In addition, because of my limited space, I built a fold-up, roll away table for it. During the process, I was amazed to find answers to all of my questions on the forum. How cool is that! So, thanks to everybody that contributed. Now I gotta go make some stuff.

Awesome build! Do you have any plans for the table? I would love to emulate it on mine!

That is beautiful man😍

I absolutely love the Murphy table-like setup. Really good job with the wire management too!

I have always wanted to do a folding table to store it out of the way, but I worry that storing the MPCNC like that will misalign the gantry.

Very nice! I love the fold-up table too.

Sorry, no plans. It was just from mind to wood. I should have made plans because I ended up doing several things twice.

It has been surprisingly resilient. I did need to re-square things after it took a hard fall during an unstable phase of the process.

Sounds like my “design” process.

I’m in the middle of printing parts for the MPCNC. I too am interested in vertically storage due to space. I could dedicate a part of the garage to a horizontal only but I love the idea of putting it away like i do my table saw. I always wondered how the 3D printed parts would hold up in that position.

My back-of-non-existent-napkin-pseudo-math ponderings leads me to believe that the weight of he steppers won’t be much of an issue, but the router/spindle might be. This can easily be mitigated by a quick-disconnect of the Z-Axis motor cable (and any other connections), and simply removing the whole tool mount for storage. This is already the preferred method for many who have multiple tools (spindle, laser, drag knife, needle cutter, plasma torch, etc.); they just have different tool mounts (complete with Z-Axis steppers) for each tool.

I think it would be fine. I wouldn’t want to drop it, but it will be ok. If you wanted to be extra careful, you could clamp the horizontal axis in place so it doesn’t sag in a funky way.

If the motors are unpowered and one axis moves quickly when you tip it, it can generate voltage and damage the electronics. So either move to the end before tipping or clamp it in place somehow.

I would think the mechanical parts should be plenty strong as long as it doesn’t fall.

The fall isn’t the problem (well, except for the generated voltage), it’s the sudden stop at the end…

My 10c worth, Great idea by the way and one I imagine we all face, well I know it is a big issue for me at any rate.

Why not make a flip up panel that pivots on the back and can then be secured to each side of the table and make a cradle on it with half circle cut outs to go around the back stainless pipe. This will support the structure before you tilt it. My worry was always how the printed feet would handle the sideways stress if turned 90 degrees. Supporting the lowest (when vertical) tube should support everything else enough.

Great Idea and one I am going to play with as well.

How have you fixed your dust extraction? Closer photos please. i am playing with a motor mount version to keep the height regardless of cutting depth, but i think I may be making a rod for my own back. Maybe fixing to the XY assembly is the better way to go.

Nice build ! Your foldable table table is dope as well.

How long did it take to build the whole setup ? What did you start to mill with ?

Hi Mark,

I considered all sorts of things, but in the end, I concluded that the gantry with router really isn’t very heavy. The parts are relatively “burly” and I over built the table. It seems that the loads from the belts in operation are likely higher than the weight. Thus, in my opinion, hanging sideways shouldn’t be an issue. Obviously, I’ll see long term, but so far, I have checked the squareness each time I get it out and I can’t see any change.

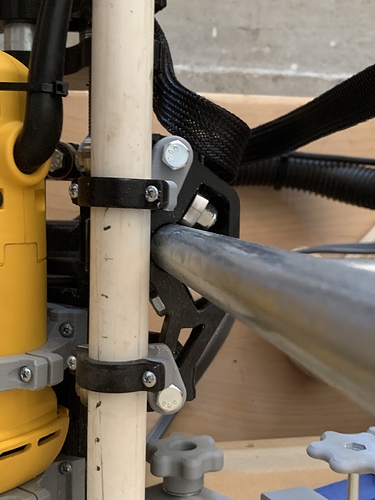

Here are a couple of pics showing how I mounted the Vacuum Tube. I’d be happy to share the STL files.

Hey Felix,

Thank you. It took me about 6 weeks to complete the build. The first thing I made was this nameplate which was made out of a pine 1 x 4. (Seemed appropriate ). Then I tried to make a box w/ lid but that didn’t go well. I learned a lot though.

Yes please! And curious what you’re using for a dust shoe?

And oh, BTW, GREAT looking build!

Thank you Flynt. My MPCNC is 1400mm x 1400mm in total to give me a 980 odd work area so a lot heavier I guess. You have inspired me to try and do something similar but I think I will try my idea and support it just in case. I have a mix of burly and non-burly feet at the moment. Thanks for your clear thinking idea though.

I see perforated angle in use for your legs. Got to be one of the most versatile materials to keep available in the workshop. All my shelving is made of that and one of the CNC cabinets as part of the dust containment. That and self drill screws. Great stuff.

I am trying to work out which is the least of the evils as far as mounting the vacuum tube. Yours is a similar solution to one of the other guys and seems logical but I really like the idea though of the nozzle moving with the Z axis for some reason, not sure why I am stuck on that. I will definitely give your idea a try and yes please, would love to share your stl’s. Time for you to open a Thingiverse profile.

Hey Mark,

Putting the vacuum on the Z axis would be better in the sense that the vacuum moves with the chip maker. The draw back according to “the man” Rudy, is that any drag on the Z axis will distort the accuracy of the machine. Mine does not collect all the chips (maybe 90%). I have posted the parts I designed to Thingverse under "MPCNC Vacuum system. It may not show up until tonight 5/20 because they have a 24 hr hold policy for new posters.