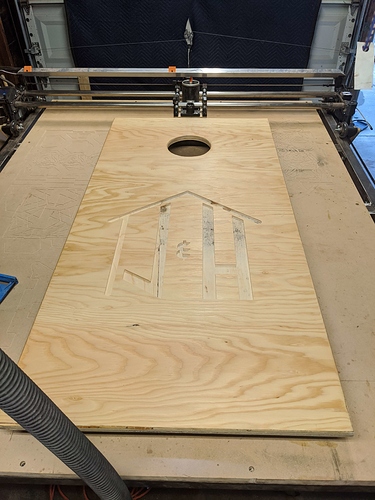

So this is the difference between an upcut and a downcut bit… From now on I’m using a downcut for plywood.

Caveats: chips need help clearing. If you make through cuts, you may get tear out on the bottom, although not as much, since the fibers are supported by the spoil board.

As long as you’re not doing a lot of channels or straight plunges, you’ll probably be ok. Just keep an eye on the chips to make sure they aren’t packing up in the cut.

For sure. I guess I could’ve clarified, if I’m doing wide (more than the endmill width) pockets in plywood I will go for a downcut bit. I had heard that the quality of the bottom of the pocket would suffer with the downcut but this came out the same. Maybe I misunderstood that and it meant exactly what @kvcummins was referring to.

It suffers if the chips build up under the bit. If you can prevent that, you’re good.

I haven’t had trouble with the downcut in slots. Just drilling exact holes. Even 1/4" holes with the 1/8" bit have been fine. For 1/8" holes, I just go down 2mm and then finish later on the drill press.