The MPCNC has been a great introduction to CNC routers and a fantastic hobby for over a year now . I’ll soon be taking the leap to a significantly larger machine that uses ISO30 tool holders! I decided to make my own tightening fixture for the new tool holders instead of purchasing one. I already had some 3/4" 6061 Aluminum in the scrap bin that was well suited for the job.

My build: 29x29 burly bruh from NC

What we’re making.

3/4" aluminum cut to rough size and marked for pre-drill.

Pre-drilled a 1/2" hole to avoid needing to plunge endmills.

Drilled a few more holes and screwed the work piece down onto the table.

Lots of adaptive clearing paths to match the profile of my tool holders.

1/8" single flute endmill with 17mm LOC

2d adaptive toolpaths

27000rpm, 2mm doc, 10% woc, 0.001" ipt

I ran a lot of separate programs while creating this part. The part hole was off by about .2mm but I was able to compensate in CAM and re-profile the pockets until I had the fit that I wanted. I was pleasantly surprised that the combination of dual end stops and g38 routines were repeatable enough to give the accuracy I needed. No visible steps when repeating a program, etc.

The air blast lower mount worked well enough to keep chips from piling up in the pocket.

The rest of the part required an end mill long enough to reach down through the 3/4" stock. I could have flipped the part and used the same 1/8" tool that I used the first go around but I didn’t want to have to re-indicate things. Picture shows test cuts with a 1/4" single flute cutter that could do a 1" DOC. This is the first time I’ve used a 1/4" tool on the MPCNC for anything other than chamfers. I probably wouldn’t try running plunge or slotting toolpaths with them but it seemed to work well enough for the 2d adaptive paths required here.

single flute kyocera 1/4" carbide endmill, 25000rpm, 2mm doc, 5% woc, 0.001 ipt

Yea can hear a the slightest bit of chatter between 9 and 6 o-clock. Never could figure out why.

Lots of tool stick out…

Ran a few quick chamfers to break the sharp edges and it’s dood enough to start using it. I’ll clean it up on the new machine when it’s complete.

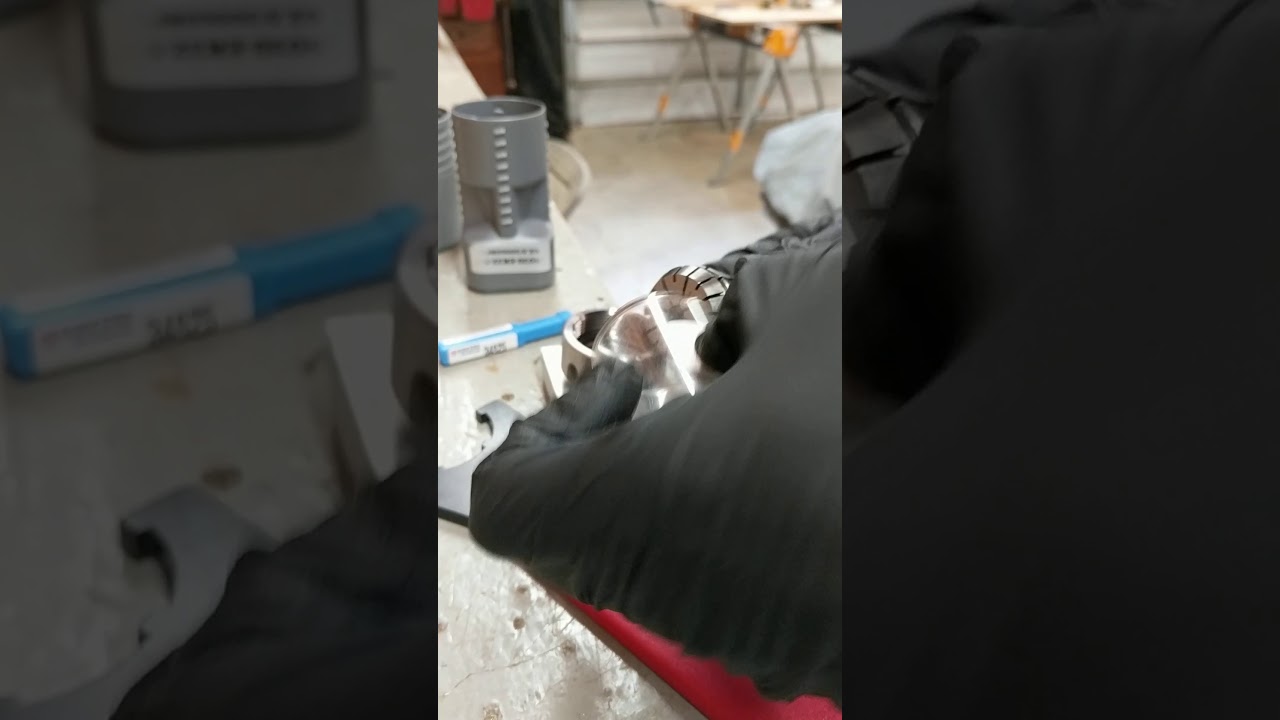

Using the fixture to load a tool:

If you don’t mind me asking, what will something like that set you back?

If you don’t mind me asking, what will something like that set you back?