Trying out different air assist options for this 2.5w engraver I have, but it’s just too weak to cut through anything. Got the ok from the wife to order a 15w to upgrade since she can’t make her jewelery ideas with this one.

25 mm/min at 100% with 4 passes to cut out this 20mm circle with the 2.5w diode… I’m hoping the 15w will be quicker

Be wary of the power output claims, especially from Chinese sources. Almost universally, for the higher output units, the Chinese now quote power as Input power, so a module quoted as 15Watts is actually around 5 Watts output power. AFAIK the most powerful single laser diode is 7.5 watts output power. If the advert claims more than that they are either pulsing the diode with a current much higher than the maximum current for that diode, which it is widely accepted will shorten its life, or there is more than one diode in the module (like this example, the cost of which is around $250, if you are looking at a substantially lower price then alarm bells should be going off! Many of the advertised as 15 watt modules will have around 3.5 Watts output power and cost around $50.

Looking at the burn marks at the start of your cutting operation, they could be down to Z commands in your gcode causing the XY axis to wait while the un-implimented Z axis to move, or perhaps you are not using GRBL’s dynamic laser power mode .

Which air pump did you go for?

Thanks for the advice, the input power on the one I bought is listed at 40w with the output listed as 15w, it was $200. I don’t like to abuse return policies but if this doesn’t seem to be much of an improvement over what I have I’ll return it. I think the out of place burn marks at different points were from me nudging the air assist around which was shifting the laser mount just a bit. I know a diode won’t cut like a c02 laser but just looking to cut through 1.5 mm basswood up to hopefully 3mm at a reasonable rate.

I considered buying the neje one from that video. I saw that video posted in another topic a few days ago and it got me inspired to try to do through cuts, I was kind of modeling what I did with my air assist after his in the video.

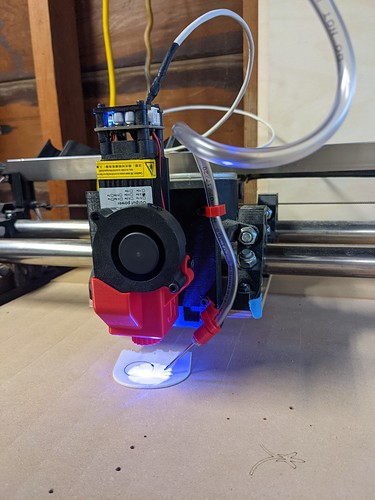

As for the air assist, I’m using my shop air compressor regulated down to 20psi for now, if I stick with this style I’ll have to look into what air pump to get.

I use about 50psi with a needle valve to throttle it, and one of those vertical ball style flow meters to keep flow around 3-20 L/min, depending on etch or cut, and cut speed. The air travels in a 1/4 tube to a 6” long 1/8 alum tube, which is bent so it is almost parallel to the laser beam, and centered on the dot. Getting parallel to the beam makes the air a lot more effective… digs deeper into the narrow kerf. Also getting it perfectly centered on the dot is not easy, but is important to do since with a small nozzle the flow area is tiny. I like to use an etch to aim the nozzle… look where the sparks and smoke stains go, and move the nozzle until it sprays evenly (not staining one side of the cut).

At the end of the day even with great air assist, cutting such thick hardwoods is going to take some passes and time, even with a legit $200 laser. Really diodes are best for etching, or if cutting is a low priority and lot sizes are around a few parts a week maybe… more than that and I would just invest in co2. Also $200 is the big chunk towards a $500 co2 machine.

You shouldn’t have a big issue cutting 1.5mm or even 4mm solid wood with a 2.5W laser. If your using ply try buying a different brand as the glue is what will limit your ability to cut ply and different manufacturers use different amounts and different types of glue.

I have cut 4mm ply with a 1.8W laser, key is higher speeds more passes and make sure you are not doing a step-down (doc) change. I think what was working for me was around 70mm/minute 100% power with 5 or 6 passes.

I don’t really agree with this. Diodes are better for engraving than co2 but you can’t directly compare different laser types. An 7W blue diode laser should cut wood as well as a 15W co2 because the higher power density of the 445nm wavelength vs the ~1000nm of a co2. Also the diode laser will be more compact, require less maintenance and last longer than a cheap co2 tube. (Keep in mind some of the cheap co2 tubes have been shown to loose as much as 50% of their output power within the first year). Also co2 uses more power and lacks the ability to do fine detailing (direct excitation of Glas tube co2 lasers do not pulse well & the larger wavelength results in a larger burn point)

You are right about the idea that if you plan on mass producing parts you should go with co2, but if that is the goal I wouldn’t recommend a cheap Chinese glass co2 laser machine.

Sounds to me like the op wants to do jewelry and general laser cutting, because of the fine details and small lot sizes and (if it’s a hobby where they may not laser anything one month and 10 things the next) I would recommend the dependability & quality of a well built diode laser over a cheap co2 machine. But that is just my $.02

This seems fishy to me, generaly a 40W input will not allow for 15W of output power. To get 15W of true output you would need 2 7.5 W diodes with good optics to join the beams and $200 seems too cheap for that. That said I’m sure it will be several times more powerful than your 2.5W.

If you want to check the quality you can remove the optics and point it at a wall about 5’ away and power it up (make sure to have good eye protection on) if it is a good quality laser head with 2 diodes you should see what looks like a square of very bright light on the wall with very few inconsistencies. Cheaper designs with two diodes with have two distinct rectangles. Single diodes will have one rectangle.

The more round and consistent the output the better results you will have, so circular>square>rectangular.

I should have the new laser sometime next week. I’m looking forward to seeing how it stacks up against my current one.

The 2.5w I have now has been great at engraving so far but taking over 10 minutes to cut out a 20mm circle from a popsicle stick is too slow to produce anything even if it is just for a hobby.

In the video I linked 2 days ago the NEJE 40 W laser module is dissected and shown to contain two laser diodes, with the specs claiming 7.5W optical power each. The video also showed the capabilities of the module, which were quite impressive, so I can believe the claimed 7.5 Watt diode spec.

The video also showed the square dot output from the module.

40 W in and 15W out is apparently possible. but I agree that $200 sounds too cheap, much more likely to be like this 40 Watt input laser…with a single 5.5 Watt diode.

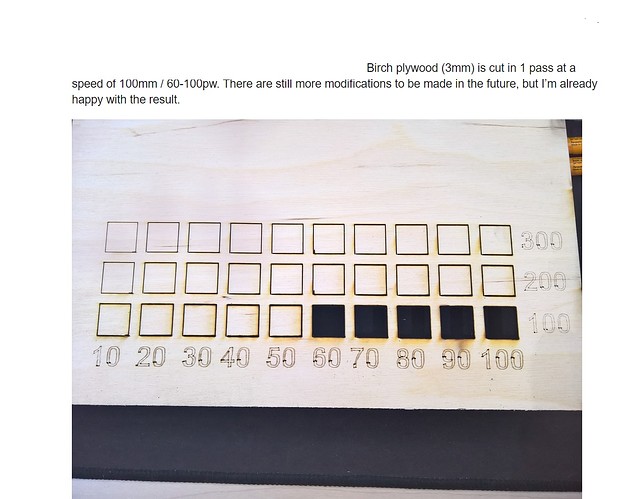

@Basstone18 Lifted from the Lightburn forum, someones test on 3mm birch plywood using a Neje 40 Watt laser - cut through in a single pass, 100mm/sec (presumably) and 60% power

Needs air assist to blow away the smoke to reduce the staining on the wood and dynamic power mode to remove the burning at the start of the squares though!

Great info. But I am reading that image to say 100 mm per minute. Aka 1.6 mm per second.

And now for info you didn’t ask for and could be wrong… aka this is my experience and understanding. Take it with salt.

When I bought my 15 watt and my 5.6 watt they both used the same kind of optic lens. They are extremely common for diode lasers so you probably have the same ones on both of your lasers. They are called something like 3 element lenses. They have an optimal focal length that is about 63 mm away from the lens. But they can work +/- 15 mm with less optimal focus. Bad news about these lenses. They only allow about 75 % of the diode power through. Ready for more bad news? Your new laser with a bigger diode will most likely have a bigger dot. As an example my 15 watt laser has a dot size roughly three times bigger than the dot on my 5.6 watt. Meaning my extra 10 watts are getting spread out over a bigger area. So I don’t get any more cutting power with my 15 than I do with my 5.6. That is part of why so many people on here can cut so well with 1.8 watt lasers.

You can buy other lenses that allow more power through. Like the G2 for metal engraving or the G8 for wood and deeper cuts.

Here is another fun concept. If the diode is getting over powered (ie. pushing 2.5 watts through a 1.8 watt) then your dot size stays small but your cutting power goes up. Also it is easier to cool an over powered small diode than it is an over powered big diode.

Also as the beam is only emitting about 2 watts you can safely use lower grade eye protection. (Hint the goggles you probably have are not likely rated for a 15 watts. Be careful).

One more tip. For deeper cuts keep your wood warm. In my experience cold wood doesn’t cut as deep.

Good luck.

Thanks for the detailed info. I’m really looking forward to seeing if this new one ends up having any benefits over my current one. I did invest in better eye protection than what usually comes bundled in with these lasers. While I’m sure they’re not industrial grade, they’re od6+ suitable for wavelengths 190nm-550nm / 800nm-1100nm, I spent $50 on them.

Whatever you do, just be sure to keep your lips away from the laser beam. And try not to spit too much on the workpiece (unless it’s on fire, then spit away). Also, high-proof alcohol consumption should be avoided for many reasons, including the inability to react fast enough to the laser changing directions, the general anesthetic properties allowing more damage to your lip(s) before your brain registers the pain, and the general lack of judgement that should preclude the partaking of said beverages when using robot-controlled lasers (or spinny hunks of metallic death, or super-heated electro-gas of destruction, or even draggy sharps of owie-ouchies). And flammable fumes emanating from your face-hole… That’s also bad…

That explains why I am always getting hurt in the shop! I will try it your way… but I’m not sure I will function any better sober.

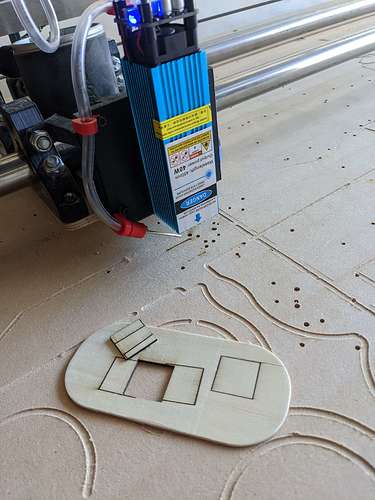

New laser just got here. So far it’s looking good, cut through 1.5mm popsicle stick material with 2 passes at 300 mm/m at 85% power. While I am concerned about duty cycle since there’s nothing in the product description, this does seem significantly more powerful than my other laser.

1.5 mm basswood 300mm/m 60% one pass. Definitely will keep dialing it in. Wife is giving me her list of jewelry making requests.

Happy wife, happy life!

That’s a serious Co2 setup. I’m not confident enough in my abilities to safely set up a tube like that. That’s awesome though.

It’s not as scary as it looks , I need to create a cover round it now I have it working though , it has some power , will cut 3mm ply in two passes on 50% power